Device, control system and control method for solidifying fly ash

A technology of fly ash and power system, which is applied to the program control of sequence/logic controller, chemical instruments and methods, electrical program control, etc. Qualified and other issues, to achieve the effect of solving the uneven distribution of heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

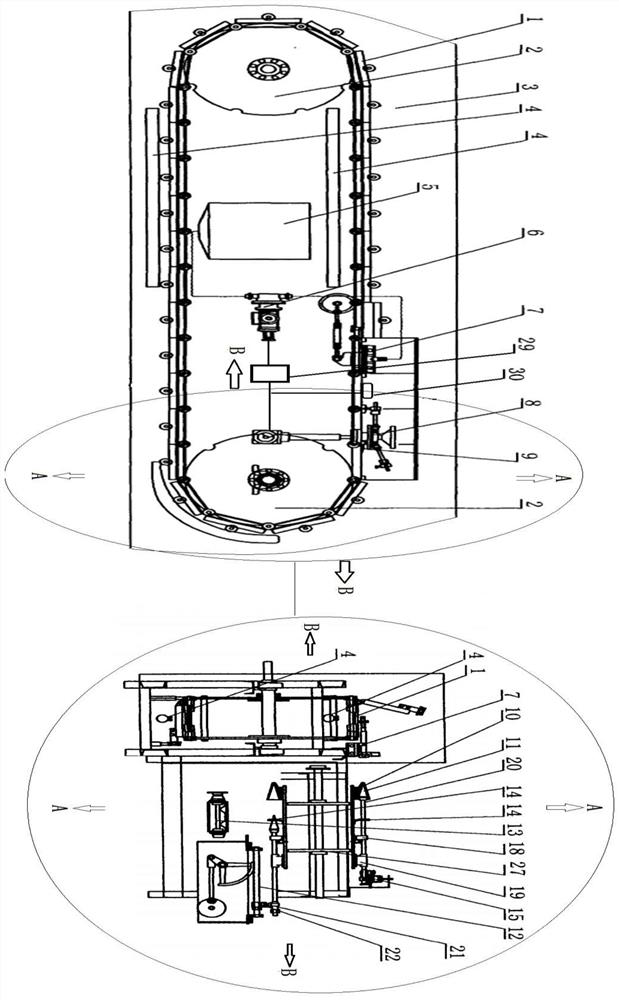

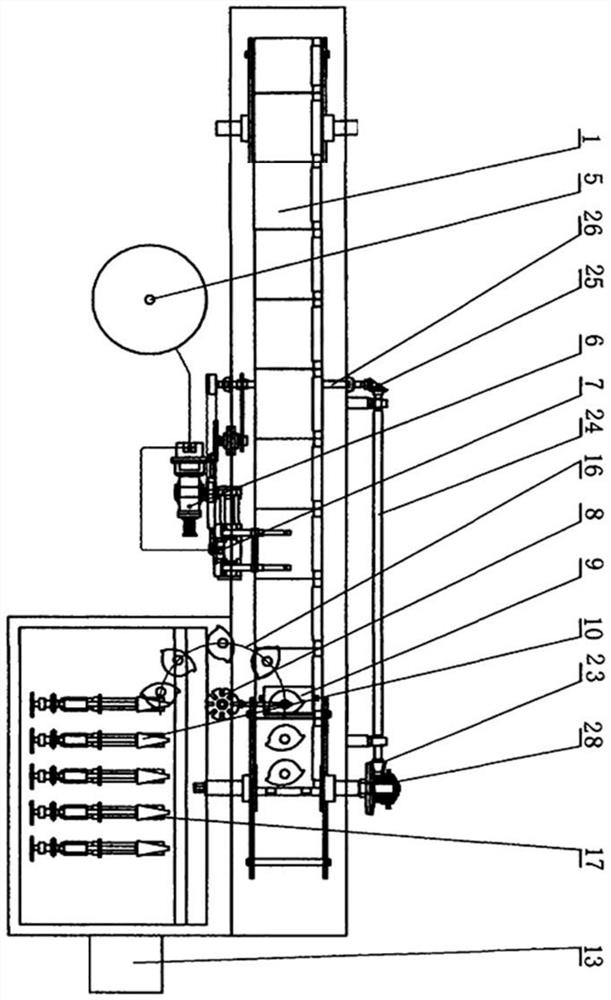

[0024] In specific implementation, as Figure 1-2As shown, the device embodiment of the present application includes a transmission power system, an electric heating system, a flake roll forming system for shaping the fly ash liquid mixture, and an electromechanical control system; wherein the transmission power system is placed by a water-cement mixed mud material connected by a pipeline Cylinder 5, mud mixing and conveying pump assembly 6 and mud conveying spray pipe 7; electric heating system is composed of transmission segment 1, transmission power runner 2, closed shell 3, formed electric heating plate 4 which are mechanically connected to each other; The roll forming system is composed of a mechanically coupled slitting member 9, a rolling forming roller control assembly 8, a screening channel 16, a mud flake roll forming assembly 10, a tapered end 11, a movable adjusting member 12, an ash solid block separation device 14, The ash solid block output device 13 is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com