Sand box structure for lost foam casting

A technology of lost foam casting and sand box, which is applied to casting molding equipment, casting molds, mold boxes, etc. It can solve the problems of low casting efficiency and cannot be improved, and achieve the effect of improving casting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

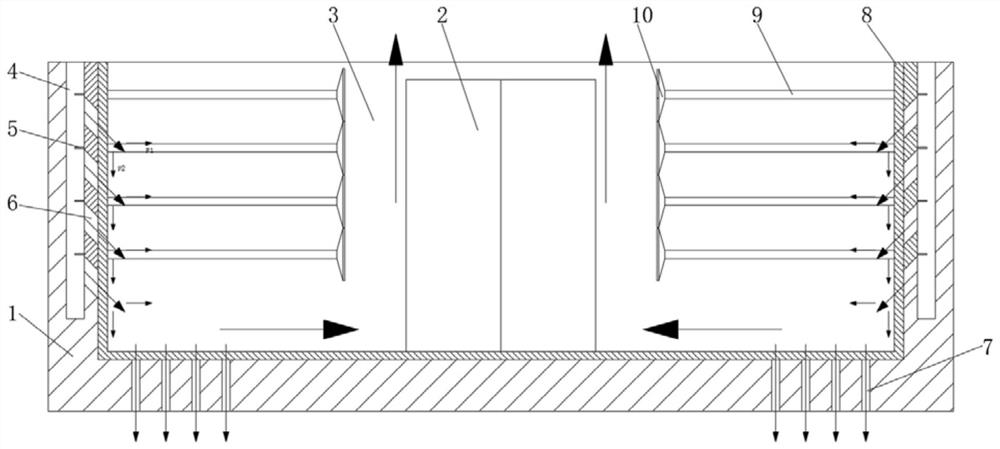

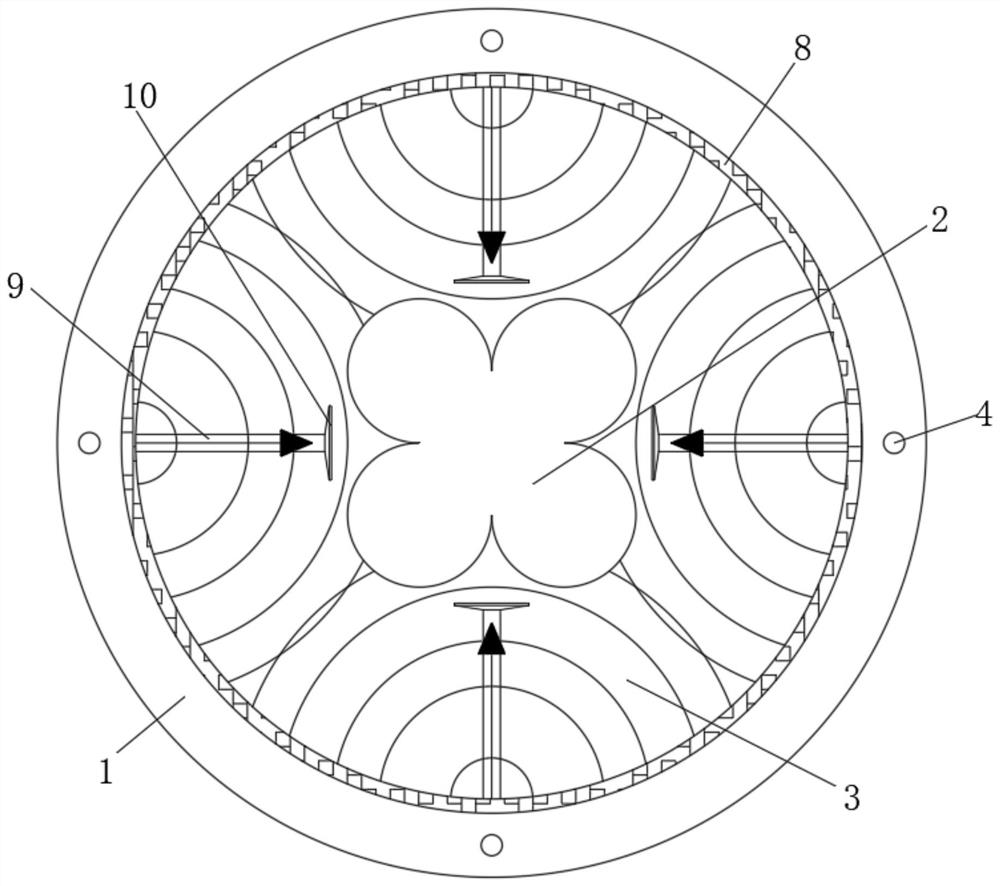

Embodiment 1

[0027] Fix the model 2 into the inner cavity of the sand box 1, fill the sand box 1 with dry sand 3, provide a certain amplitude to the sand box 1, so that the sand box 1 drives the dry sand 3 to shake, and at the same time pass into the air hole 4 The high-speed airflow, the airflow hits the vertically distributed vibrating diaphragm 5, the vibrating diaphragm 5 vibrates and produces sound waves, and part of the sound waves are directly transmitted to the dry sand 3, so that the dry sand 3 has a moving force towards the center, making the dry sand 3. The surface of the model 2 is first compacted, and a part of the sound wave is directly transmitted to the vicinity of the model 2 through the sound transmission rod 9 and the sound reinforcement plate 10 to act on the dry sand 3, so that the dry sand 3 near the model 2 is under the action of the sound wave The compacting effect is better. At the same time, the high-speed airflow circulating in the airflow hole 4 passes through th...

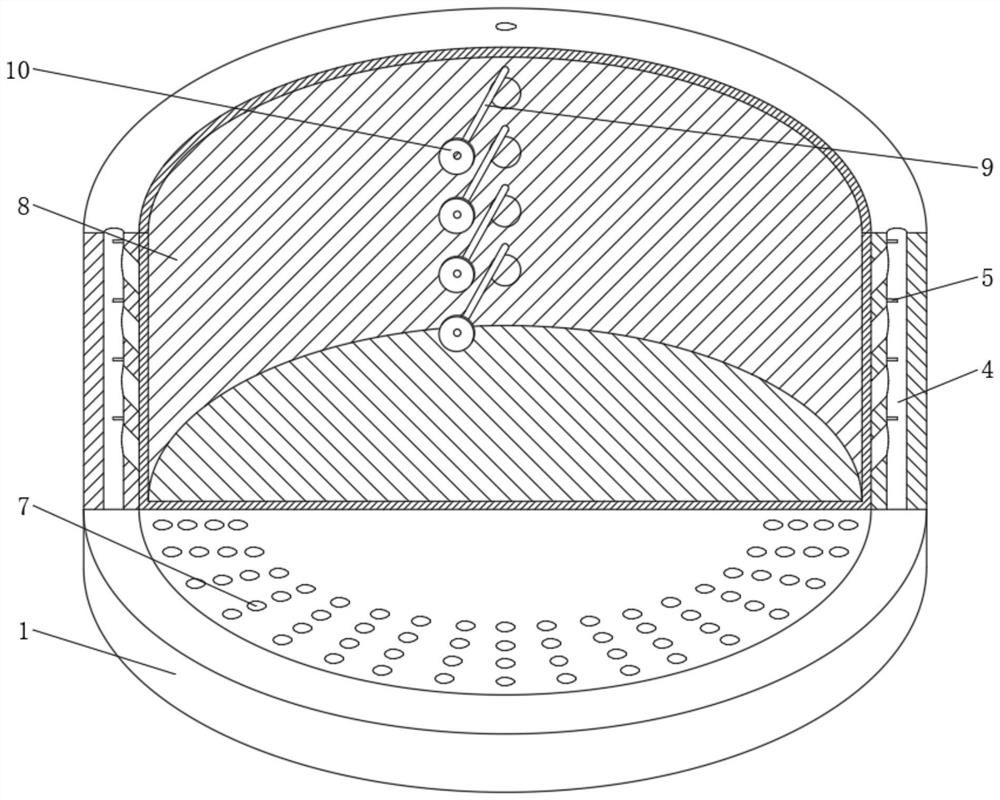

Embodiment 2

[0029] When the model 2 is of a regular shape, the compaction of the dry sand 3 can be achieved by placing a compaction plate 11 above the dry sand 3 near the outer surface of the model 2. The dry sand 3 has a pre-compression effect, and the compressed dry sand 3 shakes smaller under the vibration of the sand box 1, so that the vibration amplitude of the sand box 1 can be increased, and the compaction plate 11 After the dry sand 3 below is further compacted, the vibration amplitude of the sand box 1 can be increased again, so that the vibration and compaction efficiency of the remaining dry sand 3 is higher.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap