Industrial chemical waste liquid copper recovery device

A technology for recycling equipment and waste liquid, which is applied in the field of industrial chemistry, can solve the problems of low copper recovery rate and small volume, and achieve the effect of avoiding cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] For example figure 1 -example Figure 5 Shown:

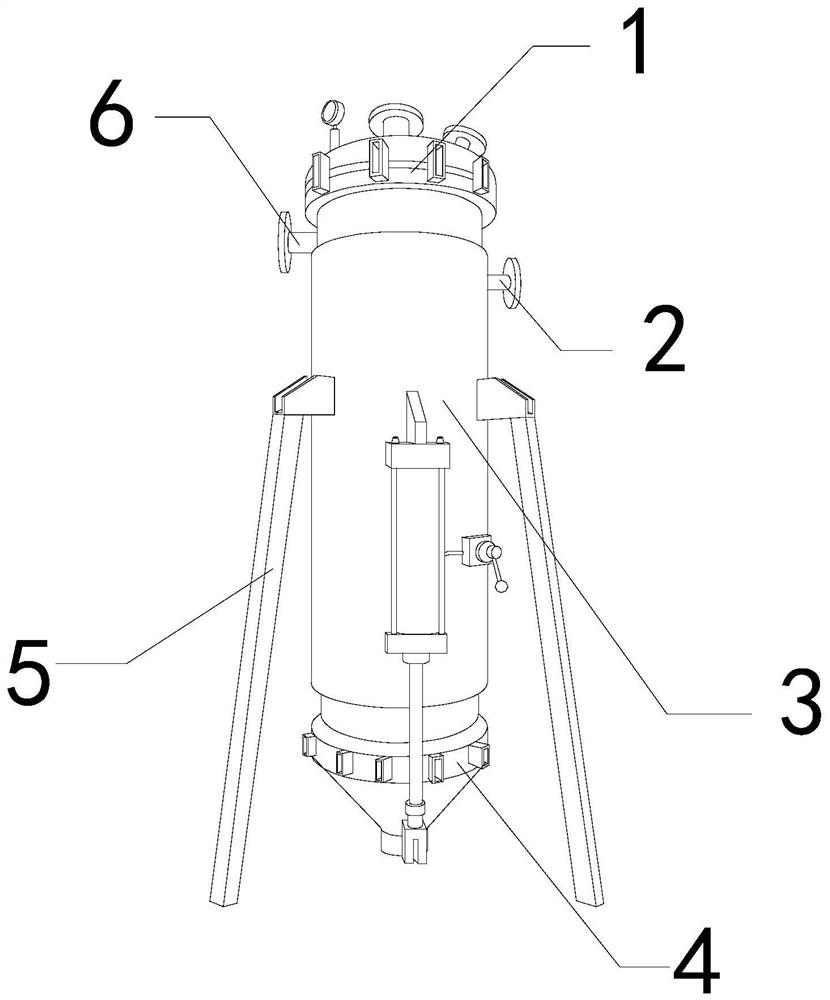

[0028] The invention provides an industrial chemical waste liquid copper recovery equipment, the structure of which includes a top cover 1, a waste liquid inlet 2, a reaction chamber 3, a filter end 4, a bracket 5, and a reaction liquid inlet 6. The waste liquid inlet 2 is installed in the reaction The right side of the chamber 3, the filter end 4 is fixed at the bottom of the reaction chamber 3, the bracket 5 is welded to the reaction chamber 3, the reaction liquid inlet 6 is connected to the internal position of the reaction chamber 3, and the reaction The cavity 3 is embedded in the lower end of the top cover 1 .

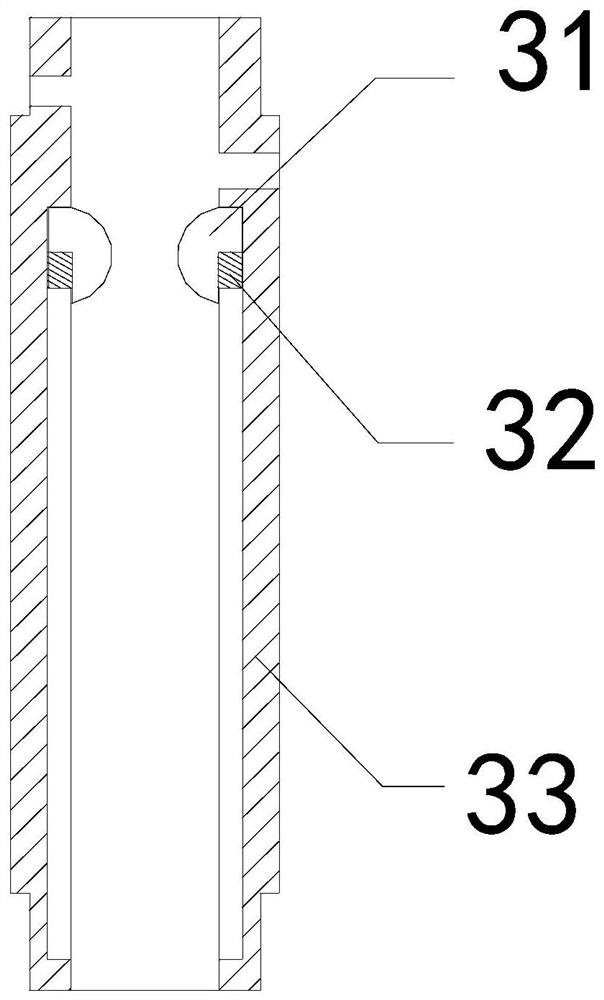

[0029] Wherein, the reaction chamber 3 includes a scraper mechanism 31, a buoyancy block 32, and a frame body 33, the scraper mechanism 31 is matched with the inner wall of the frame body 33, the buoyancy block 32 is embedded and connected with the scraper mechanism 31, The buoyancy block 32 is made of fo...

Embodiment 2

[0036] For example Image 6 -example Figure 8 Shown:

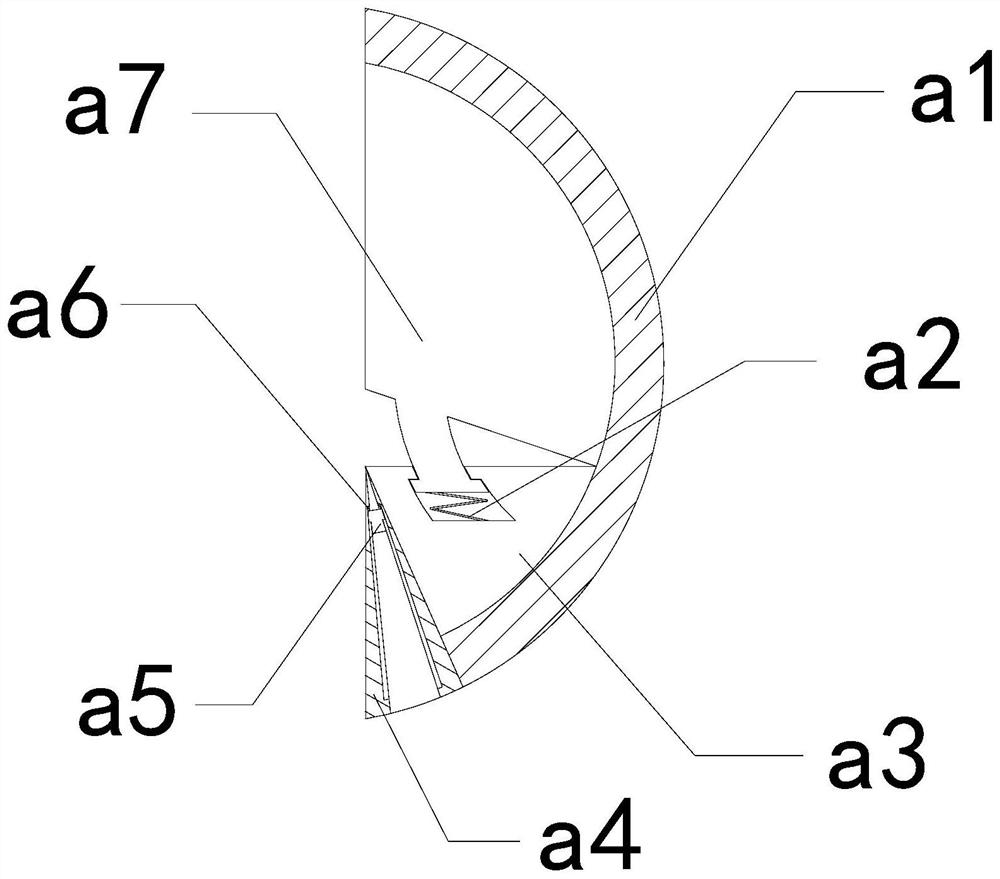

[0037] Wherein, the deformed surface a1 includes a rotating roller c1, a baffle c2, and a board surface c3, the rotating roller c1 is movably engaged with the baffle c2, and the baffle c2 is embedded and fixed on the left and right sides of the board c3, There are seven rotating rollers c1, which are evenly distributed in an arc shape between the two baffles c2, and the rotating roller c1 can be rotated by flowing on the plate surface c3 when the water level inside the mechanism drops.

[0038] Wherein, the rotating roller c1 includes a cleaning surface c11, a movable piece c12, a protective piece c13, and a joint ring c14. The cleaning surface c11 and the movable piece c12 are of an integrated structure, and the movable piece c12 is hinged to the joint ring c14. The protective sheet c13 is installed between two adjacent movable sheets c12, and there are twelve movable sheets c12, which are evenly divided into circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com