Reverse osmosis water purifier

A technology for percolating water and leveling, applied in water conservancy projects, waterway systems, sewage removal, etc., can solve problems such as easy blockage of the water filter layer, collapse of the wall, damage to the water filter layer, etc., so as to improve the drainage stability and prevent the wall body collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

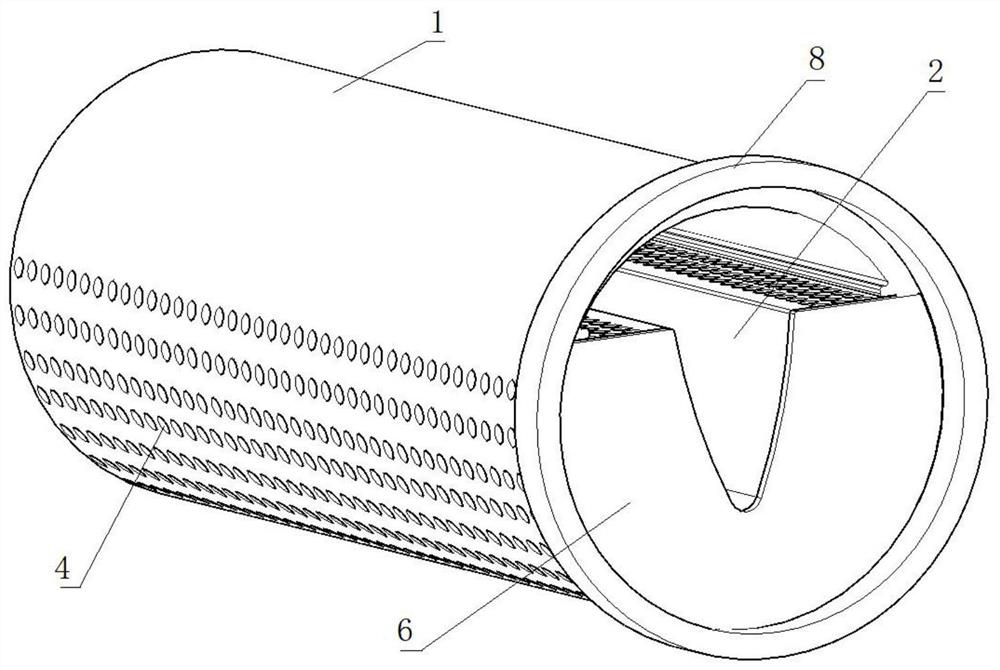

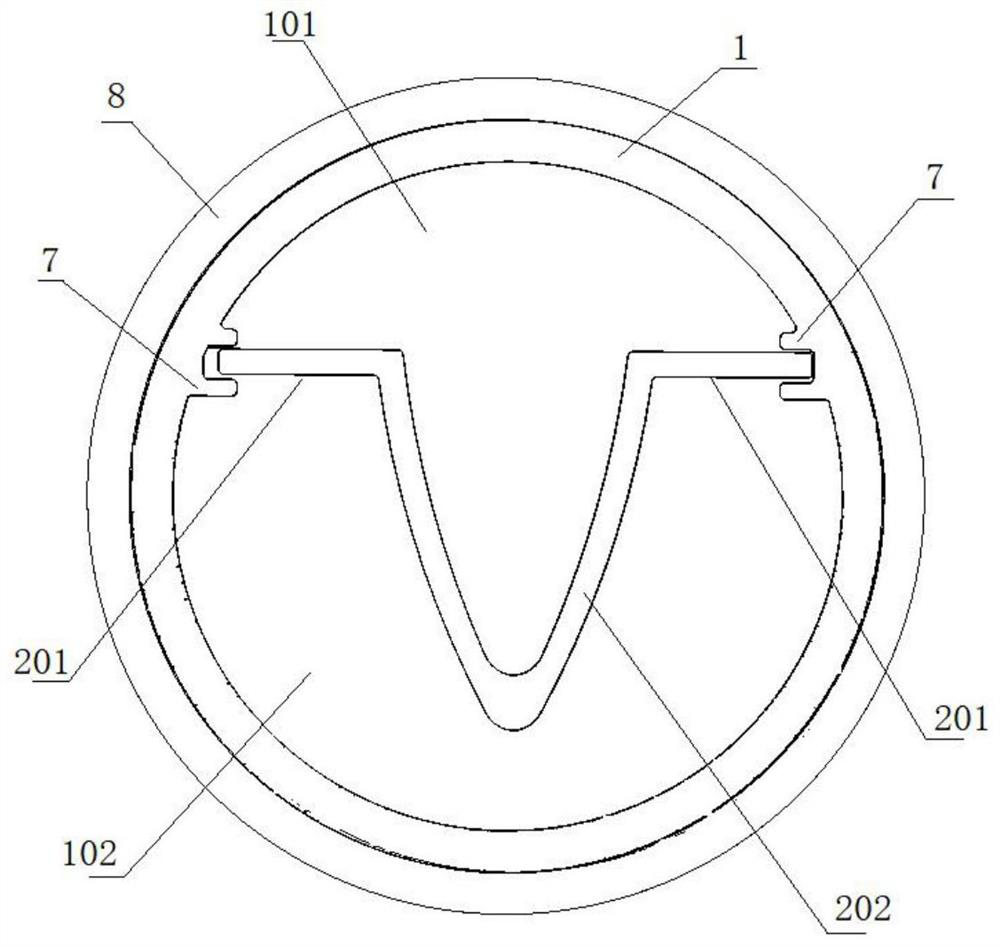

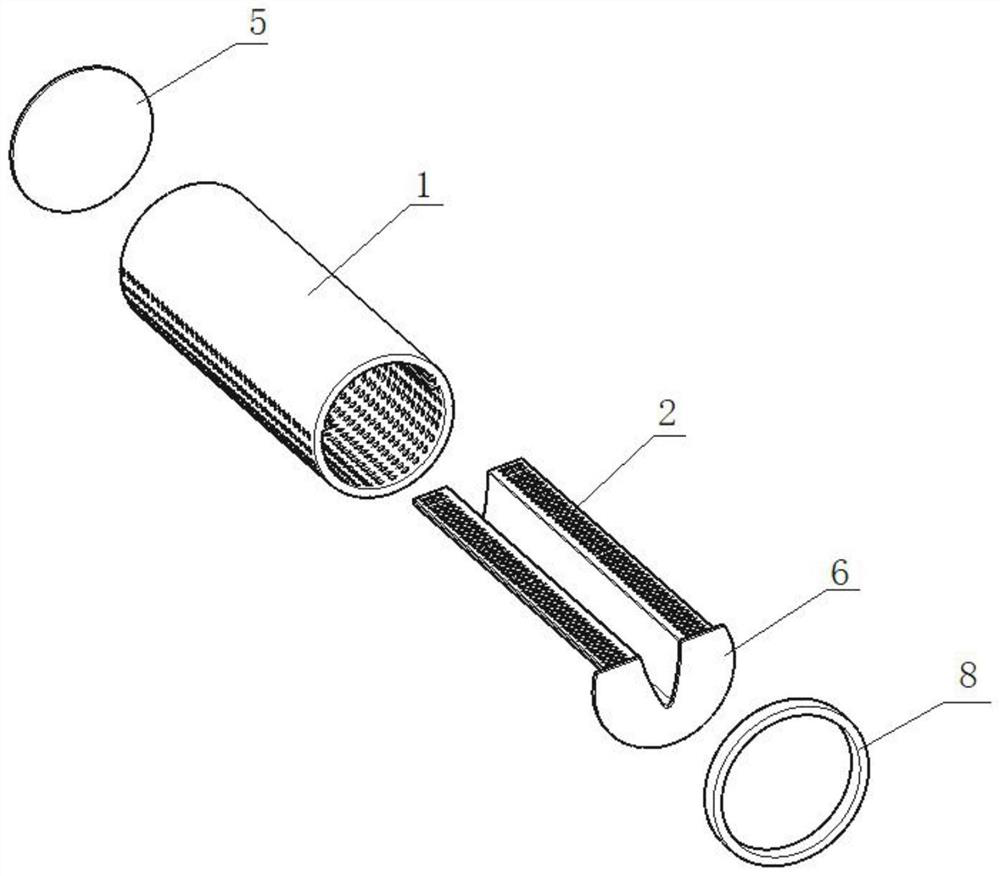

[0026] This embodiment is applicable to the scenario of drainage facilities on retaining walls, such as Figure 1-2 As shown, a reverse osmosis water filter includes a drain pipe 1 and a diverter plate 2 whose length is adapted to the drain pipe 1;

[0027] The splitter plate 2 is horizontally arranged in the drain pipe 1, and the two ends of the splitter plate 2 are connected to the inner wall of the drain pipe 1, and the splitter plate 2 divides the inner cavity of the drain pipe 1 into an upper drain chamber 101 and a lower water accumulation chamber 102;

[0028] A plurality of first filter holes 3 are uniformly arranged on the splitter plate 2;

[0029] A plurality of second filter holes 4 are uniformly provided on the pipe wall of the lower water collecting chamber 102;

[0030] One end of the drain pipe 1 is provided with a first sealing plate 5;

[0031] The other end of the drain pipe 1 is provided with a second sealing plate 6 , and the second sealing plate 6 is pr...

Embodiment 2

[0055] This embodiment is suitable for farmland irrigation scenarios, low-lying water seeps into the reverse osmosis water filter, and when the land is dry and needs to replenish water, pump water from the main outlet of the drainage pipe 1 of the stand-up water filter to flow into each The branch pipe of the reverse osmosis water filter is discharged into the soil, so that the roots of the plants can absorb water, forming a combination of supply and drainage, and avoiding the inconvenience of digging pits on the surface of the land for agricultural machinery.

[0056] Further, the reverse osmosis water filter provided by the present application can be cleaned, and can be reversely flushed from the outside of the water outlet to the inside by a water pump at regular intervals, and the silt will not be washed away due to the blocking of the diverter plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com