Method for increasing metal recovery rate of waste circuit boards

A waste circuit board, recycling rate technology, applied in chemical instruments and methods, electrostatic effect separation, solid separation and other directions, can solve problems such as environmental pollution, unsatisfactory recycling effect, etc., achieve efficient recycling, ensure continuity and effectiveness, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

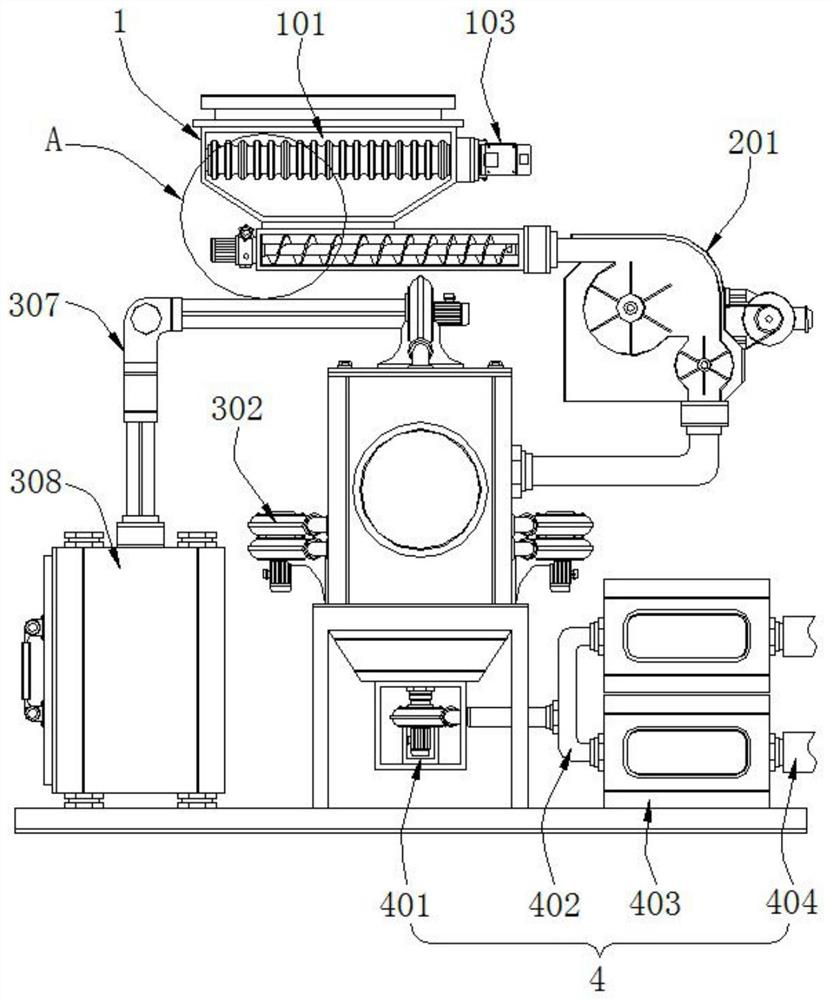

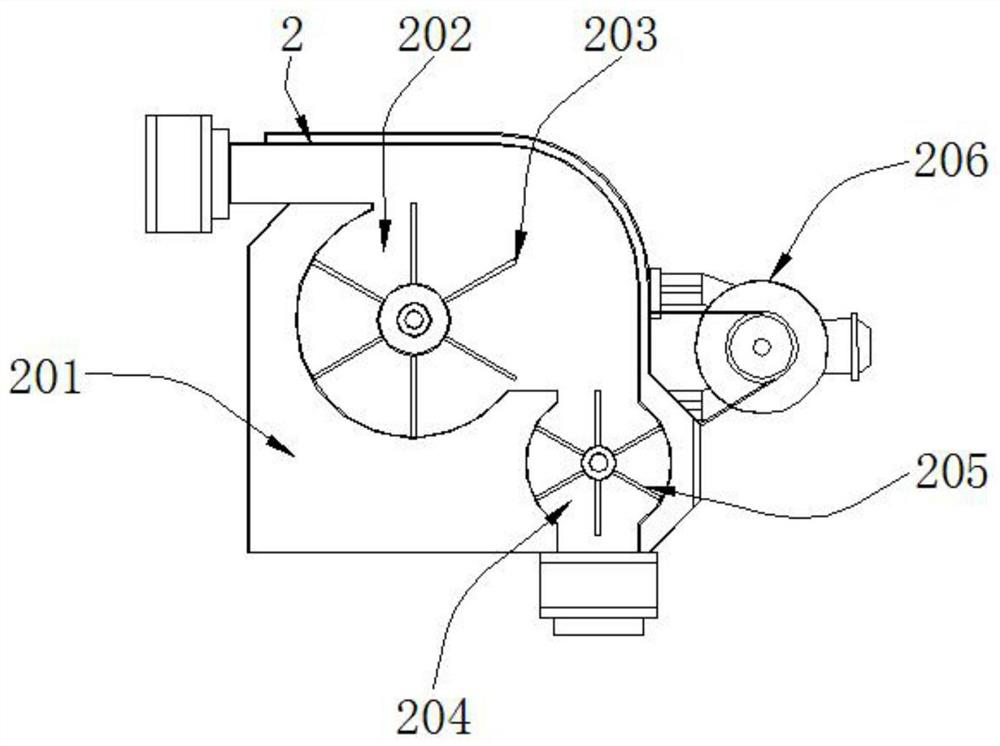

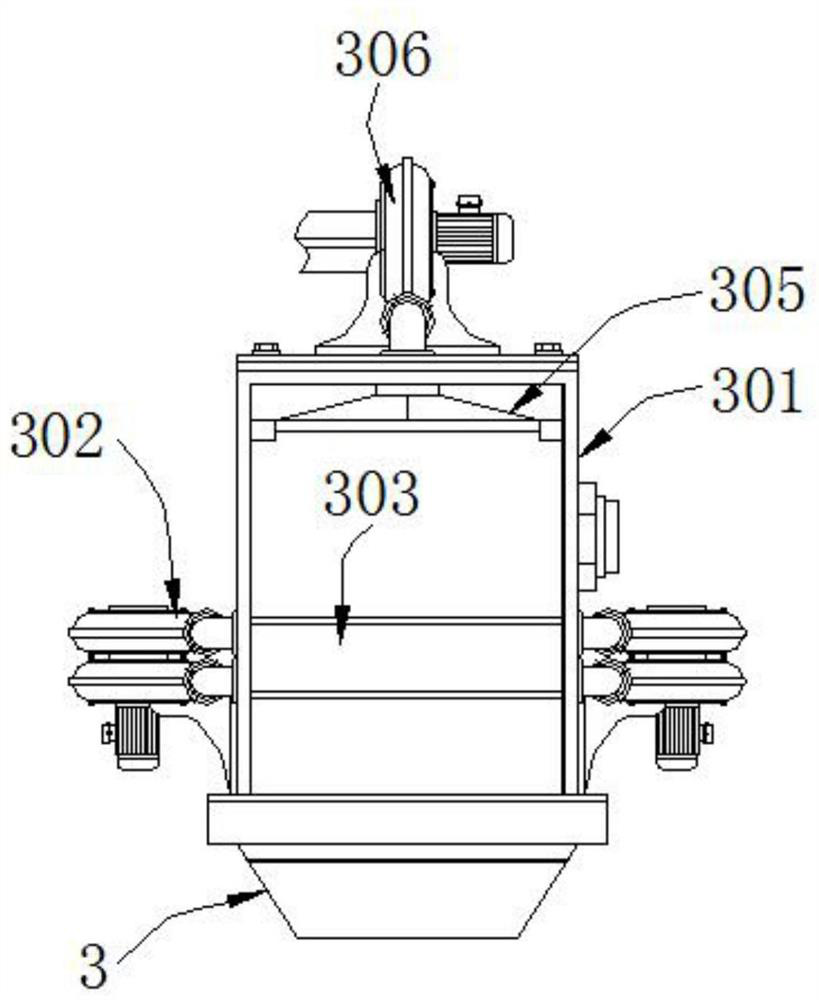

[0035] see Figure 1-5 , a method for increasing the metal recovery rate of waste circuit boards, comprising a crushing assembly 1 and a separation assembly 4, the right side of the crushing assembly 1 is connected with a quantitative assembly 2, and the lower end of the quantitative assembly 2 is connected with a screening assembly 3, the screening assembly 3 includes a separation chamber 301, a fan 302, an air outlet pipe 303, an air outlet 304, a chip suction port 305, a suction fan 306, a conduit 307, and a waste collection bin 308, and fans 302 are arranged on both sides of the separation bin 301. One side of 302 is connected with an air outlet pipe 303, and the upper end of the air outlet pipe 303 is provided with an air outlet 304, the inner upper end of the separation bin 301 is provided with a chip suction port 305, and the upper end of the chip suction port 305 is connected with a suction fan 306, The left side of the suction fan 306 is connected with a conduit 307, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com