Production testing device and method for non-full-tube flowmeter

A technology for producing testing and flow meters, which is applied in the direction of testing/calibrating devices, measuring devices, testing/calibrating volume flow, etc. It can solve problems such as inaccurate results and achieve the effect of improving detection efficiency and improving the level of detection automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

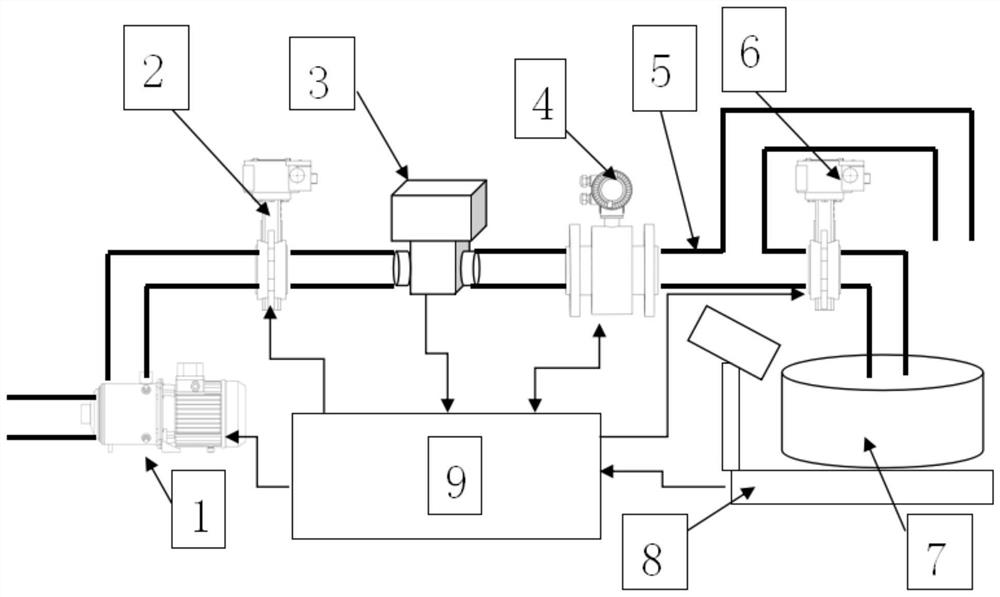

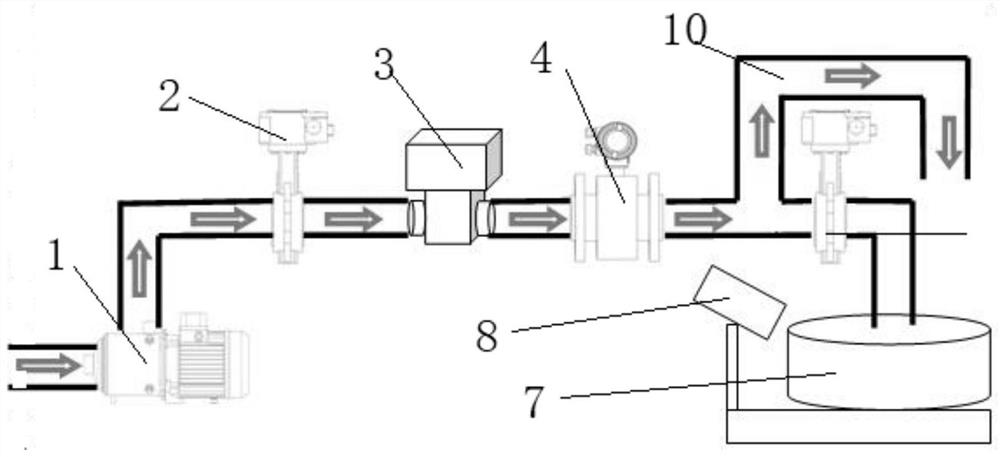

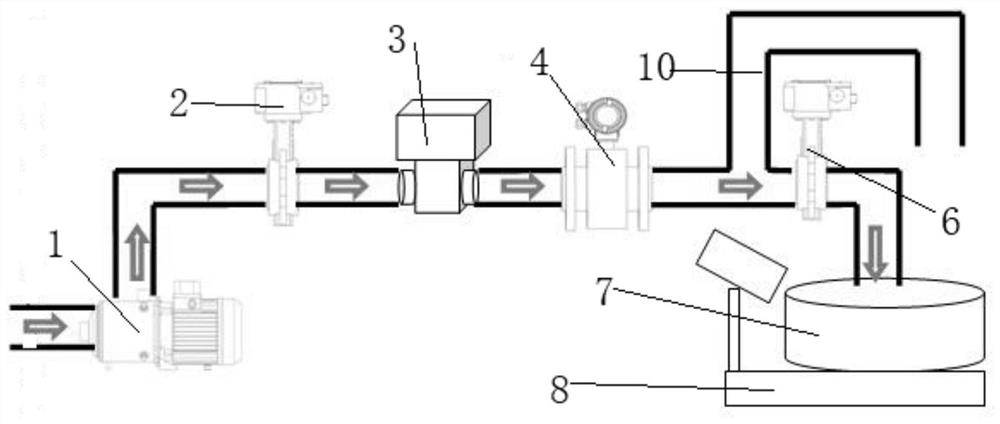

[0034] Such as figure 1 As shown, the part-filled pipe flowmeter production test device includes a measuring channel arranged horizontally, and one end of the measuring channel is connected to a water supply device, and the water supply device includes a water pump 1, and the input end of the water pump 1 is connected to the The water source is connected, the output end of the water pump 1 is connected with the first electric valve 2, and the height of the water pump 1 is lower than the measuring channel.

[0035] The water outlet end of the first electric valve 2 is connected with a flowmeter standard meter 3; the flowmeter standard meter 3 is connected with the partial pipe flowmeter 4 to be tested, and the front end of the partial pipe flowmeter 4 is connected with a flow meter Meter standard table 3; the back end of the part-filled pipe flowmeter 4 is connected with a flowmeter outlet measuring pipe 5, and the back end of the flowmeter outlet measuring pipe 5 is connected ...

Embodiment 2

[0046] The present invention also discloses a test method based on a partial pipe flowmeter production test device, comprising the following steps:

[0047] 1. First, calibrate the empty pipe parameters of the flowmeter when the pipe is dry;

[0048] 2. In the case of water flow, open the first electric valve 2, and when water enters the measuring cylinder 7, immediately close the water pump 1 and the first electric valve 2, so that the water fills the entire pipe of the partially filled pipe flowmeter 4, and then Carry out zero calibration when the water is still;

[0049] 3. Measure the full-scale calibration of the part-full pipe flowmeter 4 when the pipe is full; after the reading of the electronic platform scale 8 is reset to zero, open the first electric valve 2, start the water pump 1, and adjust the first electric valve 2 to make the flow rate reach The full-scale value of the part-full pipe flowmeter 4, the liquid passing through the part-full pipe flowmeter 4 is fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com