Finished product testing method and device and circuit board testing method and device

A test method and circuit board technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of high cost and low efficiency, and achieve the effect of improving efficiency and reducing hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

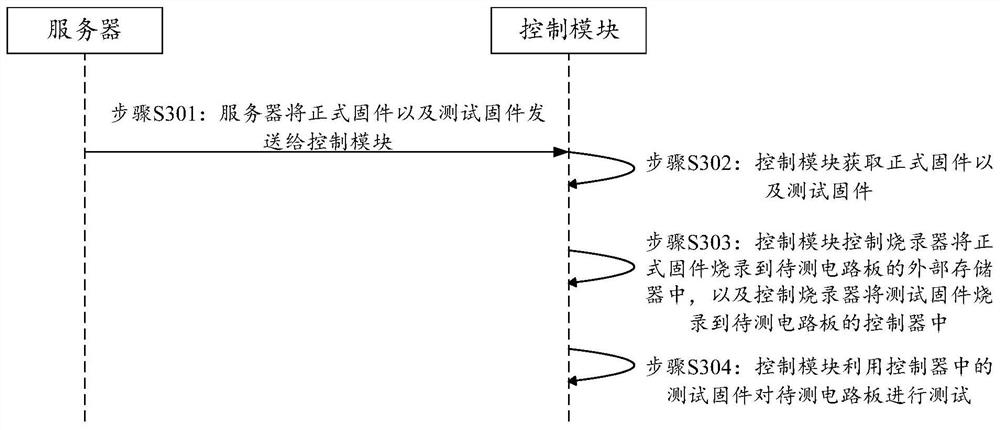

[0054] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

[0055] During the production process of electronic products, a series of tests usually need to be completed on the production line before they can be put on the market for sale. The length of the test time is related to the production cost, the comprehensiveness of the test is related to the product quality, and the product quality seriously affects the market reputation and after-sales costs. Therefore, it is particularly important to test the electronic products before launching them.

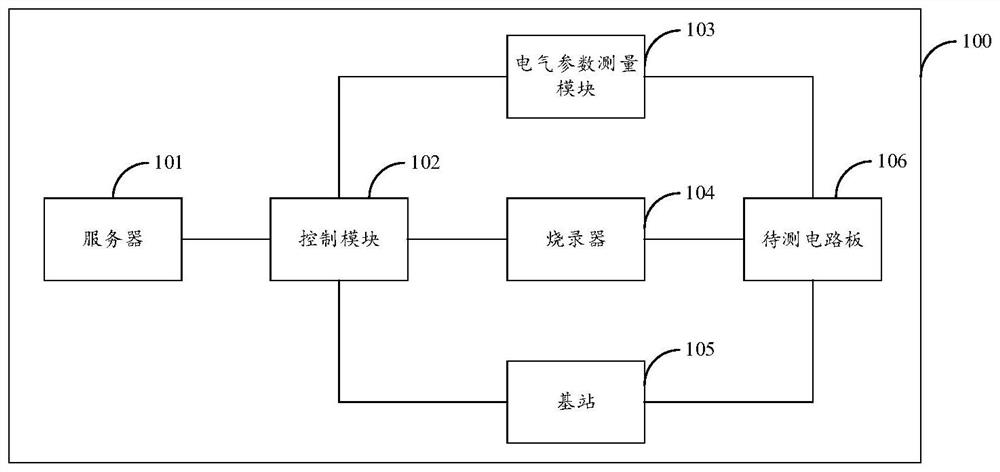

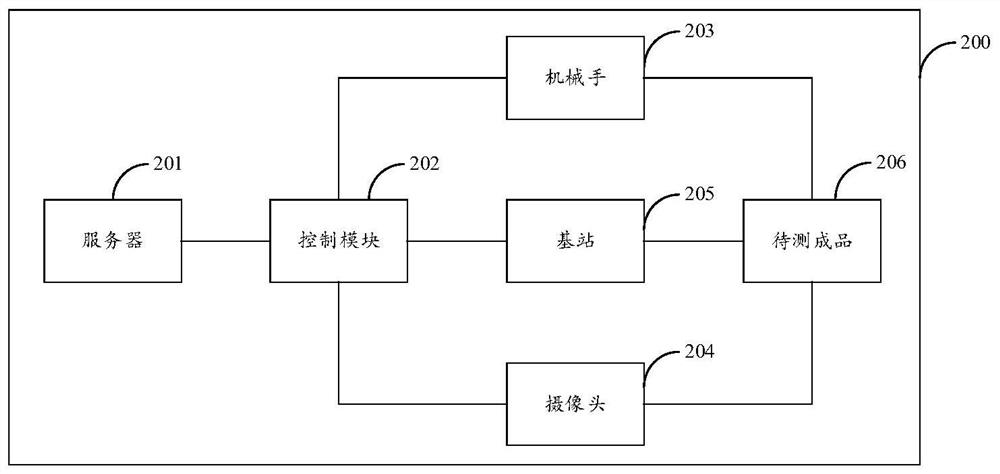

[0056] One of the most important components in electronic products is the circuit board with communication function made by Printed Circuit Board Assembly (PCBA) process. The finished circuit boards are tested. When testing the circuit board and the finished product, it is necessary to use the test firmware to tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com