Adjustment system and method for display device in optical module

A technology for display devices and optical modules, applied in optical components, optics, instruments, etc., can solve problems such as being unsuitable for batch display device assembly, production, imperfect assembly and adjustment processes and tools, and increased production costs. The effect of realizing the automation of assembly and adjustment and improving the efficiency of assembly and adjustment according to the needs of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

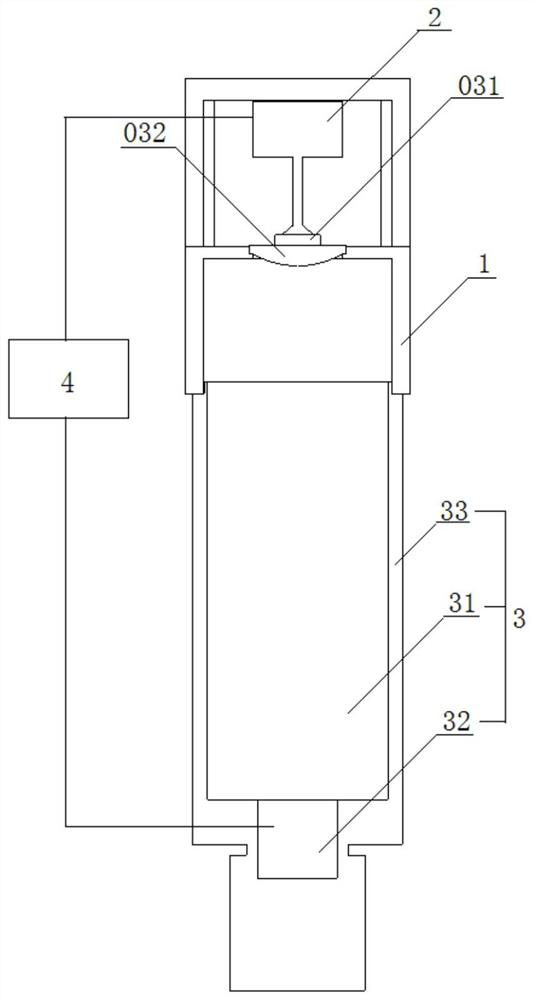

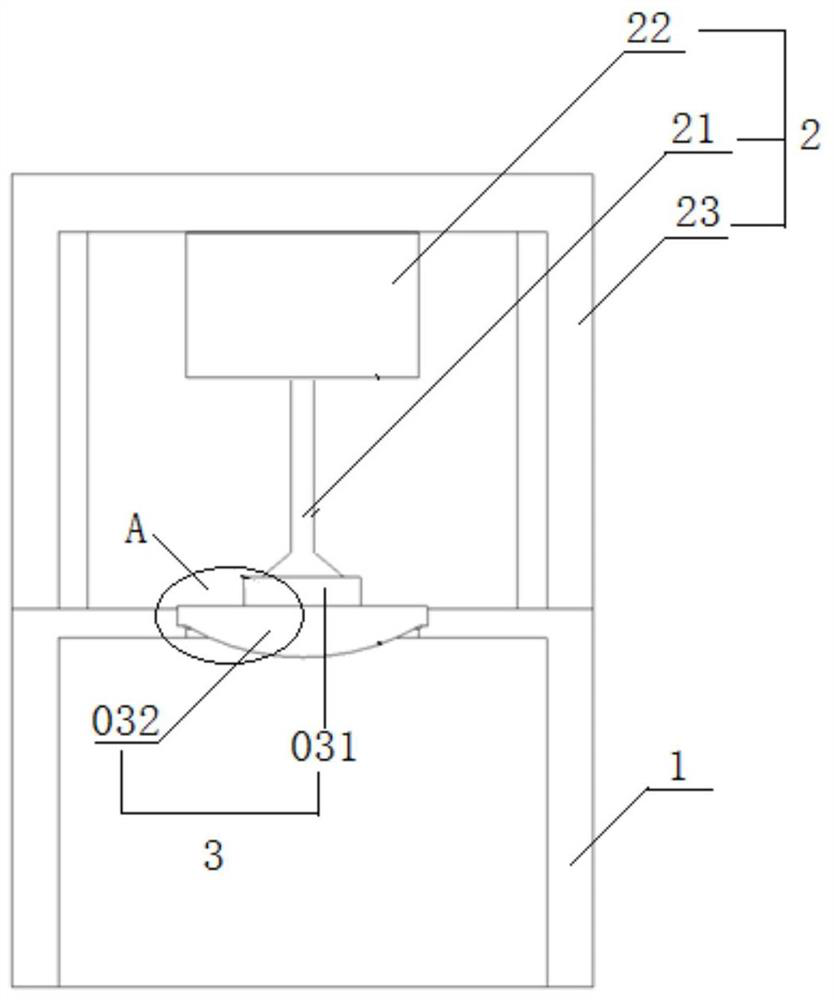

[0064] Figure 2A It is a structural example of the display device installation and adjustment system in the optical module of the present invention. Such as Figure 2A As shown, the assembly and adjustment system of the display device in the optical module includes an alignment fixture 1, an adjustment mechanism 2 and an image acquisition device 3, wherein:

[0065] Alignment jig 1 is used for precise clamping of planar convex lens 032, image 3 In the shown embodiment, the alignment fixture 1 is a hollow structure provided with a chamber 11, and the upper part is provided with a through groove 12 communicating with the chamber 11, and the two side walls of the through groove 12 are provided with holes for clamping a plane convex lens 032. benchmark bit, Figure 2C In the shown embodiment, the concave reference inner step 13 on the upper part of the two side walls of the through groove 12 matches the reference outer step 0321 provided on the outer edge of the planar convex...

Embodiment 2

[0072] Such as Figure 2A As shown, on the basis of Embodiment 1, a processor 4 is added, and the data output interfaces of the camera 32 are all connected to the processor 4, and the camera 32 transmits the alignment image of the display panel 031 captured to the processor 4 for processing and display. , the calculated center of gravity offset and angle offset between the actual position of the display panel 031 and the target position are displayed in any one or more forms of text, graphics, icons, voice prompts, etc., saving the operator from observing, The calculation and conversion time further improves the efficiency.

[0073] Preferably, the data output interface of the driving mechanism of the adjustment platform 22 is connected to the processor 4, and the processor 4 generates a control instruction according to the center of gravity offset and the angular offset between the actual position of the display panel 031 and the target position obtained, and sends it to The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com