Patents

Literature

55results about How to "Adapt to mass production needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for automatically switching day and night modes based on RGB-IR sensor

PendingCN108377340AImprove accuracyImprove the quality of monitoringTelevision system detailsColor signal processing circuitsInfrared lampSystem stability

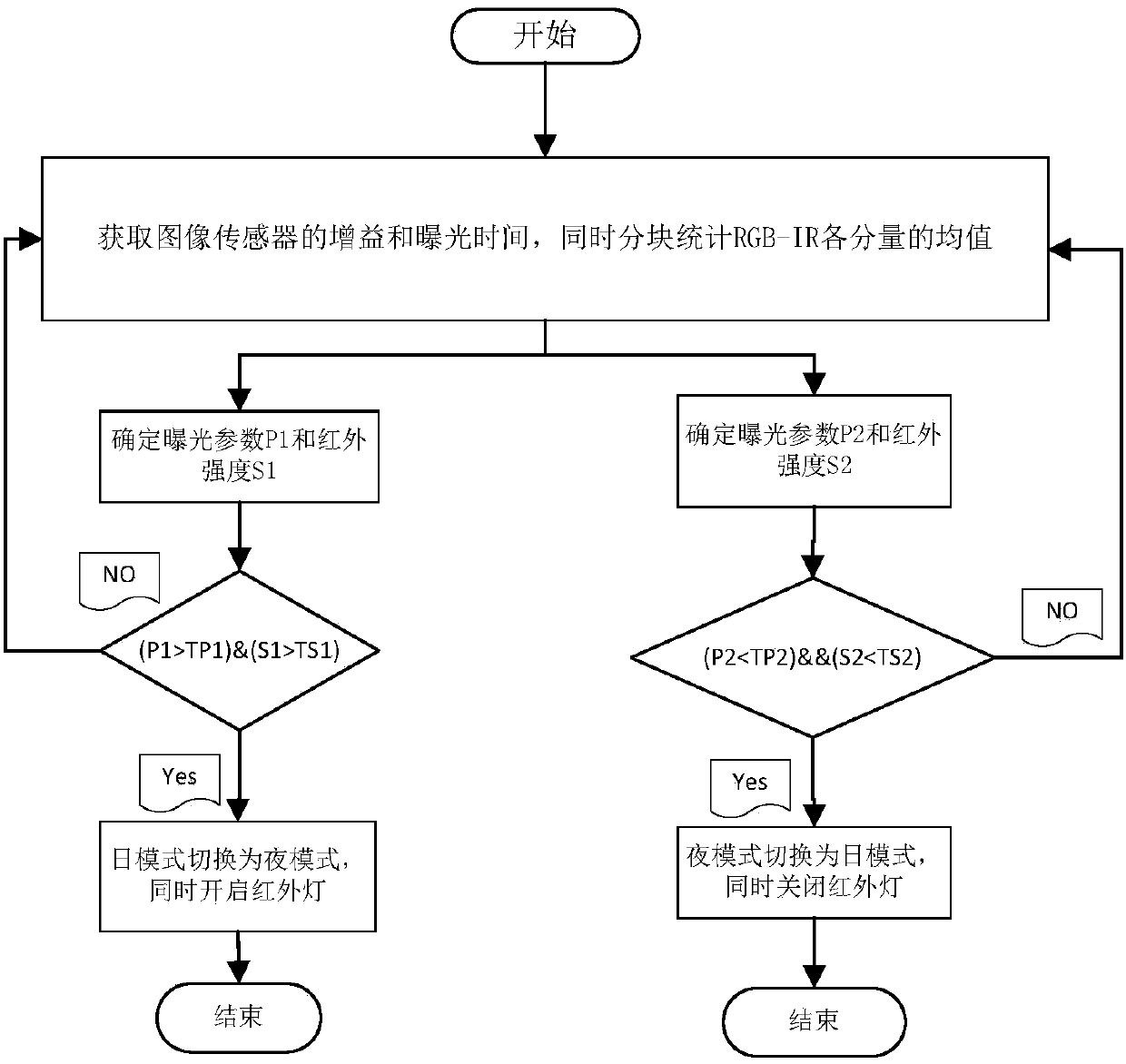

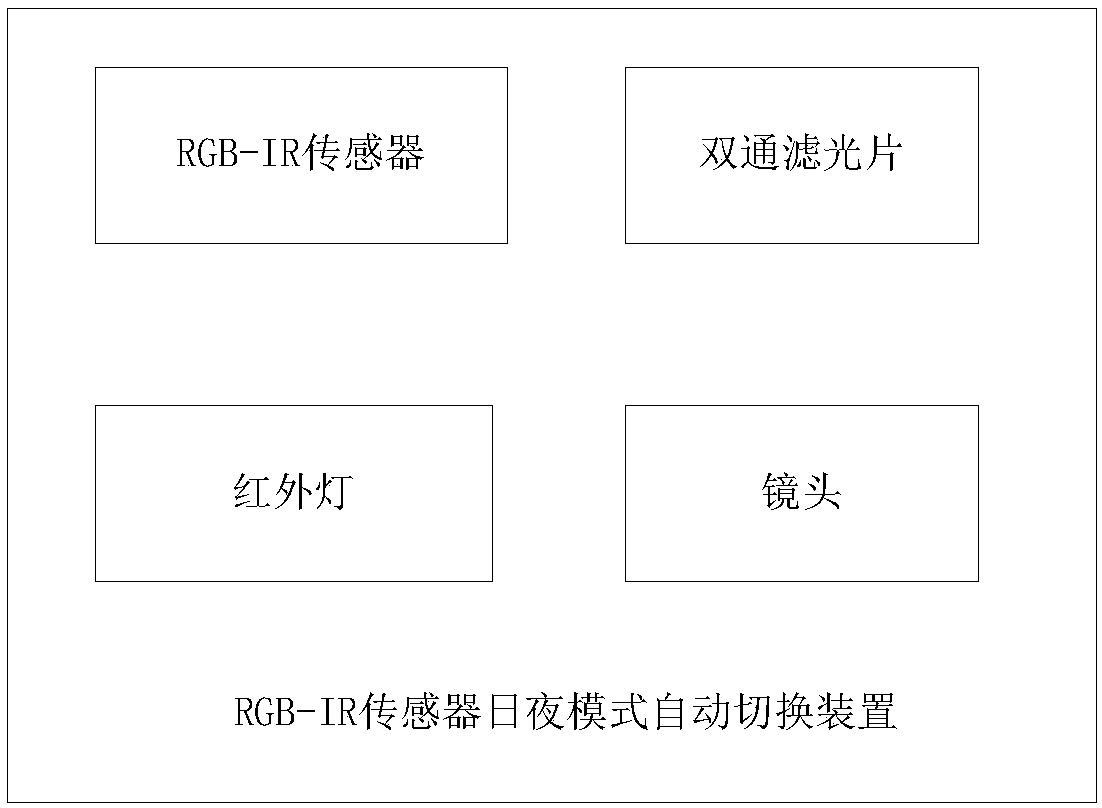

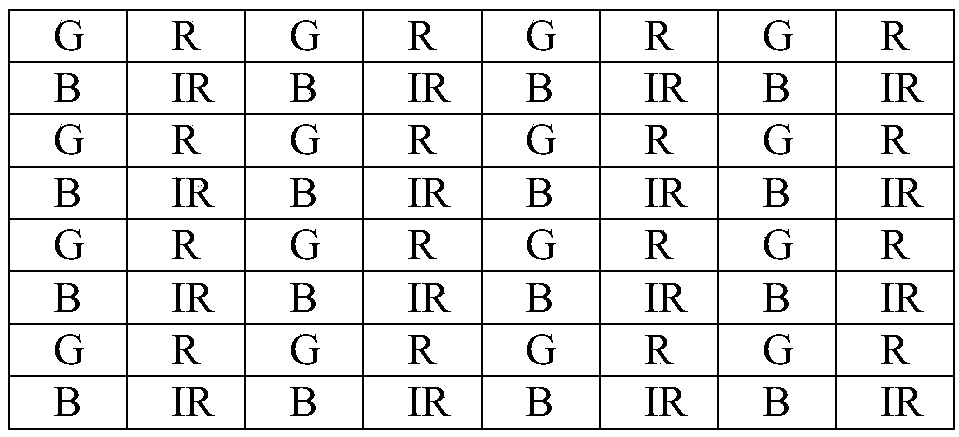

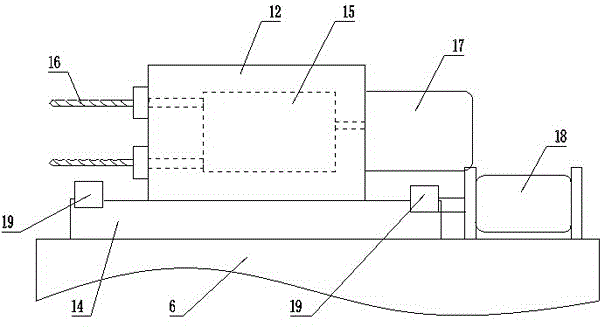

The invention provides a method and apparatus for automatically switching day and night modes based on an RGB-IR sensor. The device comprises the RGB-IR sensor, a two-pass filter, lens and an infraredlamp. The method comprises the following steps: obtaining a gain and an exposure time of the RGB-IR sensor, and performing block statistics on the RGB and IR color component means of the Bayer data;determining an exposure parameter P1 according to the obtained gain and exposure time, and calculating image average saturation S1 based on the statistical RGB component mean; if (P1)TP1)&&(S1)TS1), switching the day mode into the night mode, and meanwhile turning on the infrared lamp; determining an exposure parameter P2 according to the obtained gain and exposure time, and calculating image average saturation S2 based on the statistical RGB component mean; and if (P2(TP2)&&(S2)TS2 ), switching the night mode into the day mode, and turning off the infrared lamp. By adoption of the method andapparatus, the accuracy of day and night switching threshold can be improved, the misjudgment of the day / night switching mode and the problem of switching back and forth between the infrared lamp arereduced, the hardware cost is reduced, and the system stability and reliability are greatly improved.

Owner:杭州雄迈集成电路技术股份有限公司

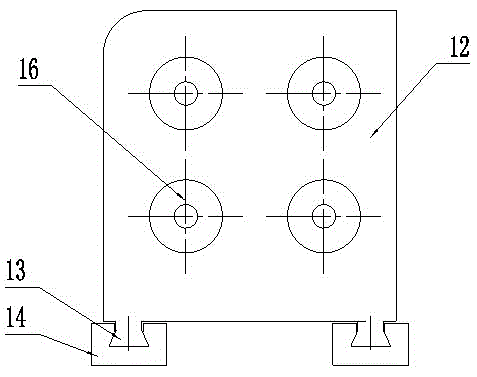

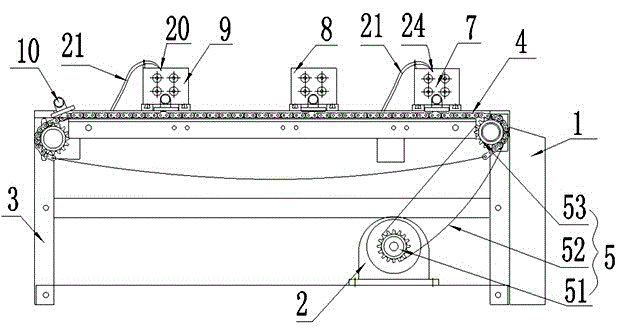

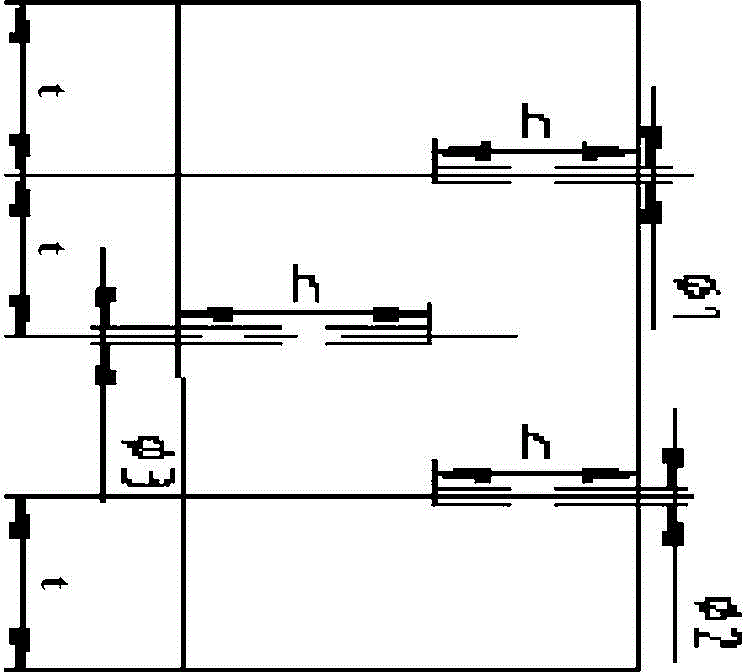

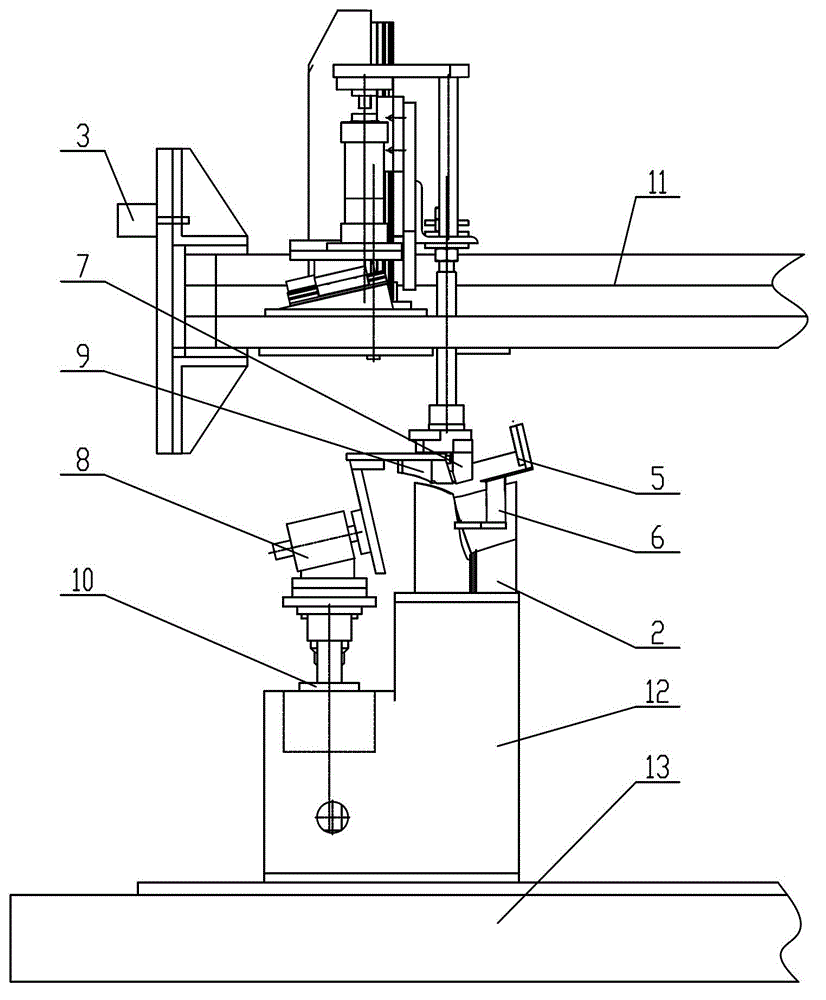

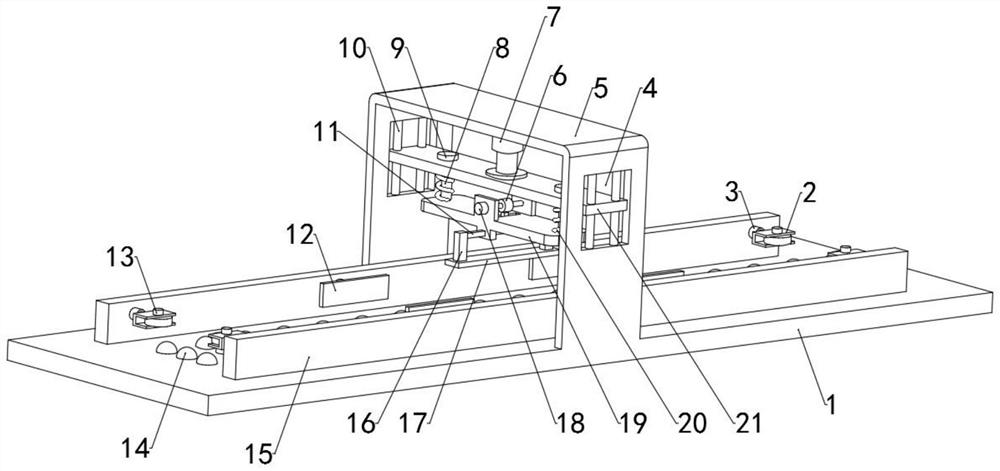

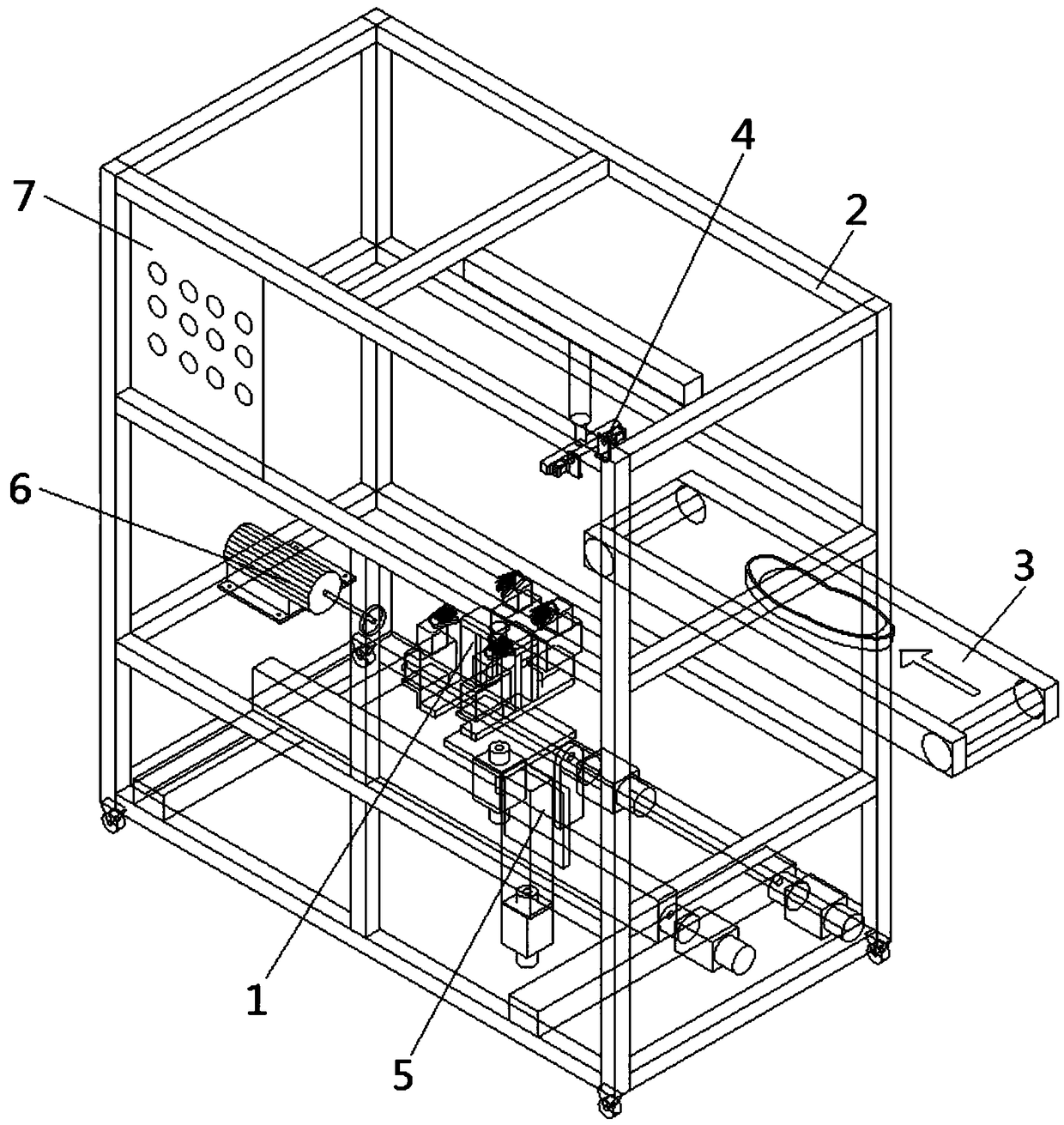

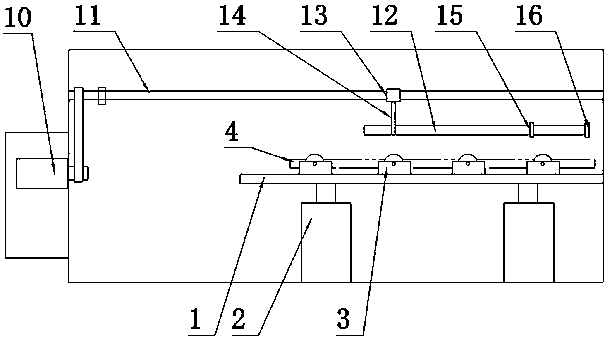

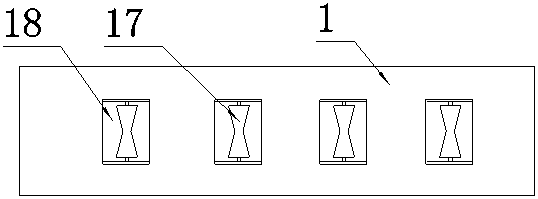

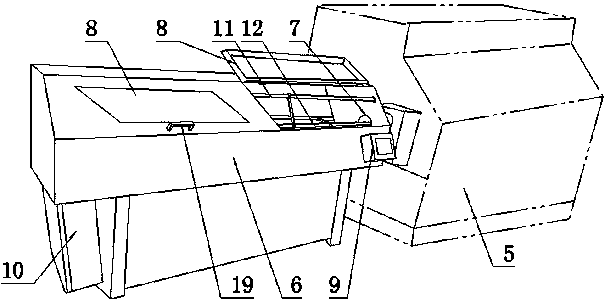

Two-sided drilling combined machine tool

InactiveCN105058059AGuaranteed accuracyReduce labor intensityOther manufacturing equipments/toolsMetal working apparatusMotor driveMaterial consumption

The invention discloses a two-sided drilling combined machine tool and relates to the technical field of cold machining machine tools. The two-sided drilling combined machine tool comprises a control box, a main motor and a rack, wherein a conveying belt is arranged in the middle of the rack; the control box is arranged on one side of the feed side beside the rack; the main motor is connected with the conveying belt by a transmission mechanism; workbenches are arranged on the top of the rack; the workbenches are arranged at two sides of the conveying belt; bottom hole processing devices, orifice chamfering devices and tapping devices are symmetrically arranged at two sides of the conveying belt; the main motor, the bottom hole processing devices, the orifice chamfering devices and the tapping devices are connected with the control box; clamp bodies are arranged on the conveying belt at intervals; the clamp bodies are used for clamping to-be-processed box bodies; and two ends of the clamp bodies are matched with the workbenches at two sides by pin rollers. The main motor drives the conveying belt to drive the to-be-processed box bodies clamped on the clamp bodies to pass bottom hole processing work stations, orifice chamfering work stations and tapping work stations in sequence, so that drilling and tapping are finished, the labor and material consumption is reduced, and the processing efficiency is improved.

Owner:孙立民

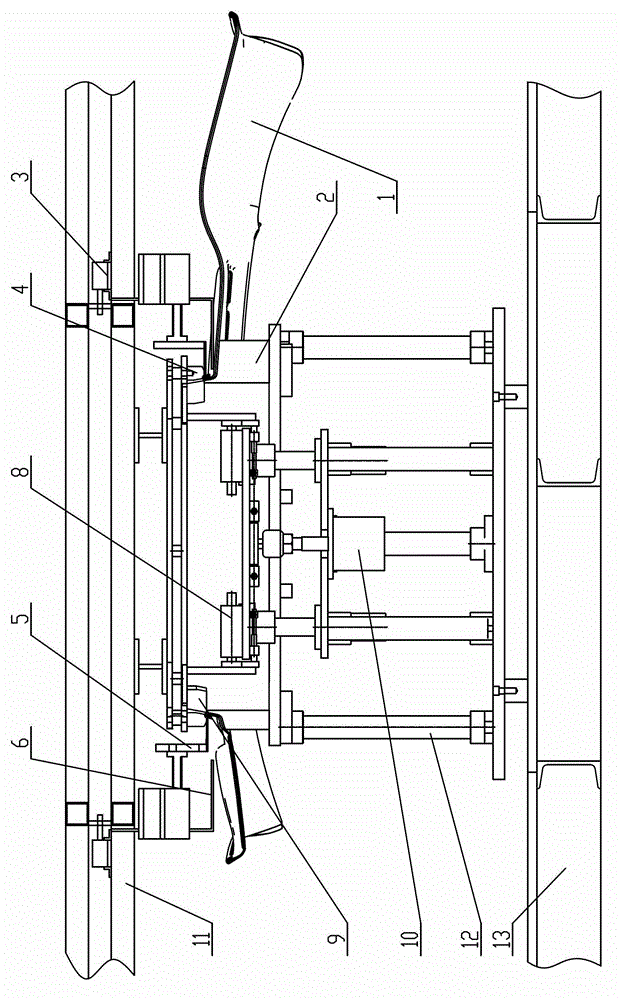

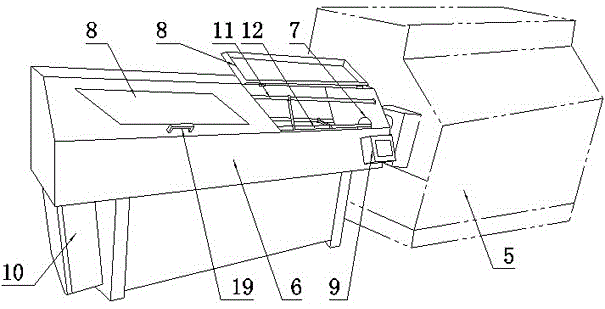

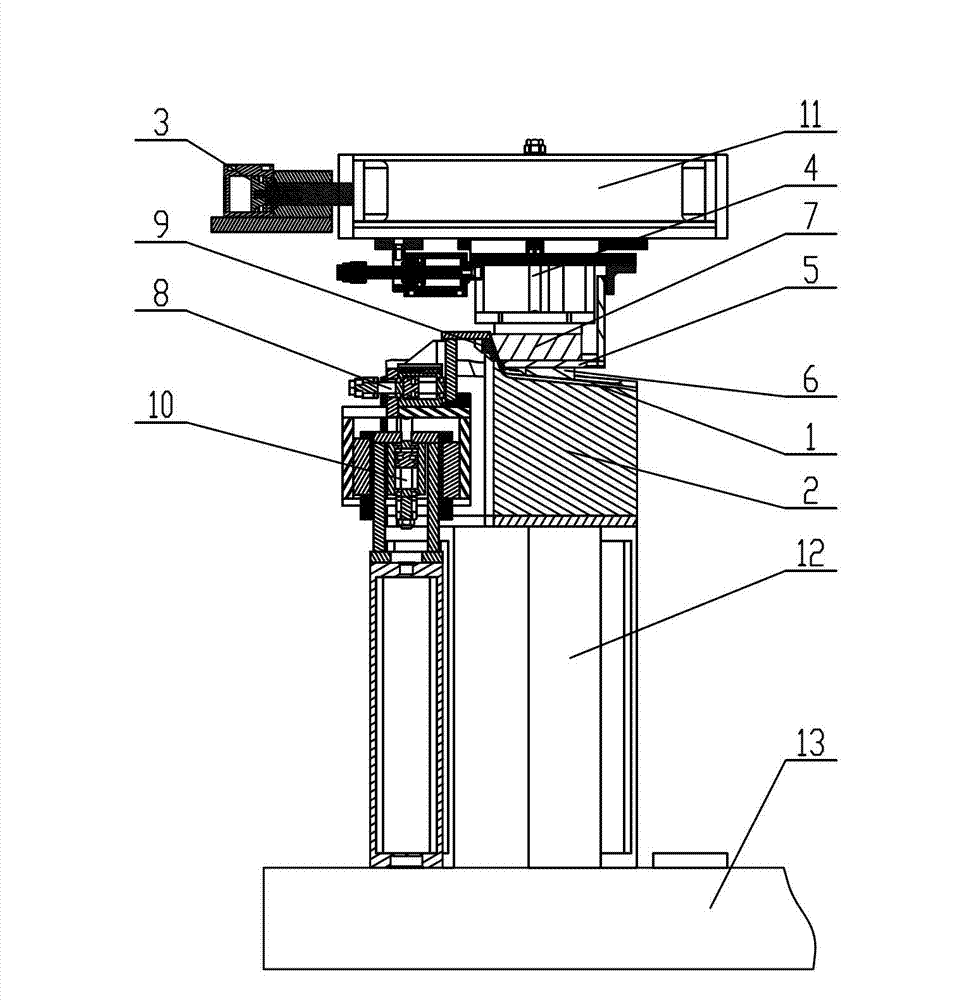

Automobile roof skylight flanging machine

InactiveCN102941669AReduce labor intensityReduce consumption costHigh volume manufacturingEngineering

The present invention relates to an automobile roof skylight flanging machine. A rack is provided with an upper workbench and a lower workbench which are mutually parallel. The side surface of the upper workbench is provided with a locking device. The bottom of the upper workbench is mounted with a skylight heating mold, a skylight inserting blade and an elastic platen. The elastic platen is located outside the skylight inserting blade. The skylight heating mold is located inside the skylight inserting blade. The lower workbench is mounted with a skylight flanging clamping assembly mechanism corresponding to the skylight heating mold. The skylight flanging machine performs flanging shaping for products through the skylight heating mode and the skylight flanging clamping assembly mechanism, thus the production efficiency is improved, labor intensity of workers is reduced, production cost of the products is saved and energy consumption cost is saved. The skylight flanging machine is simple and compact in structure, reasonable in layout and easy to operate, helps to improve product quality and is applicable to the mass production in the automobile industry.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

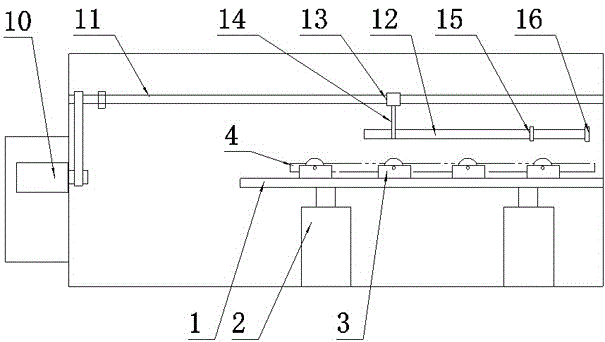

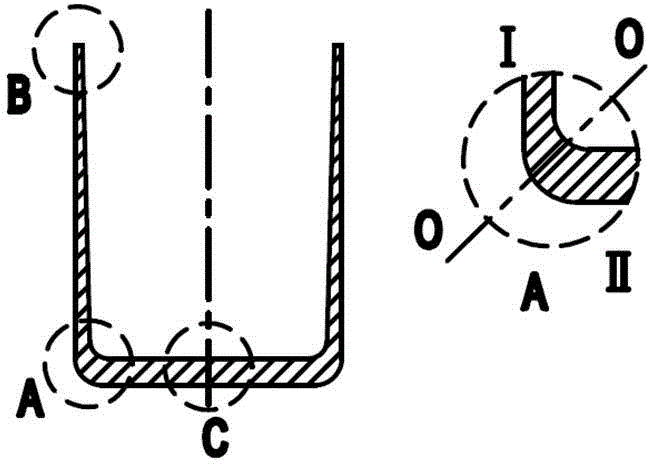

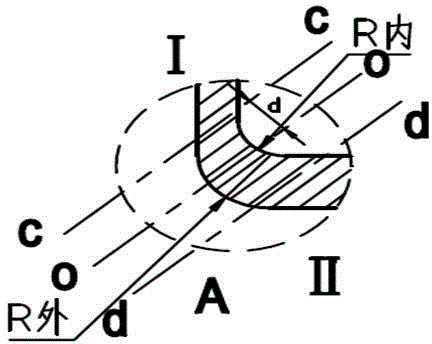

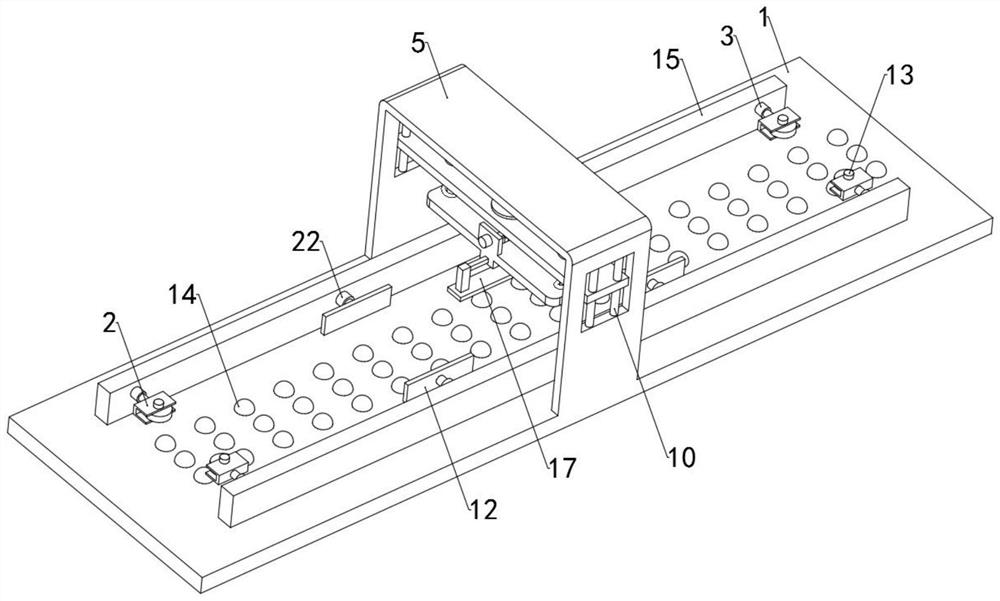

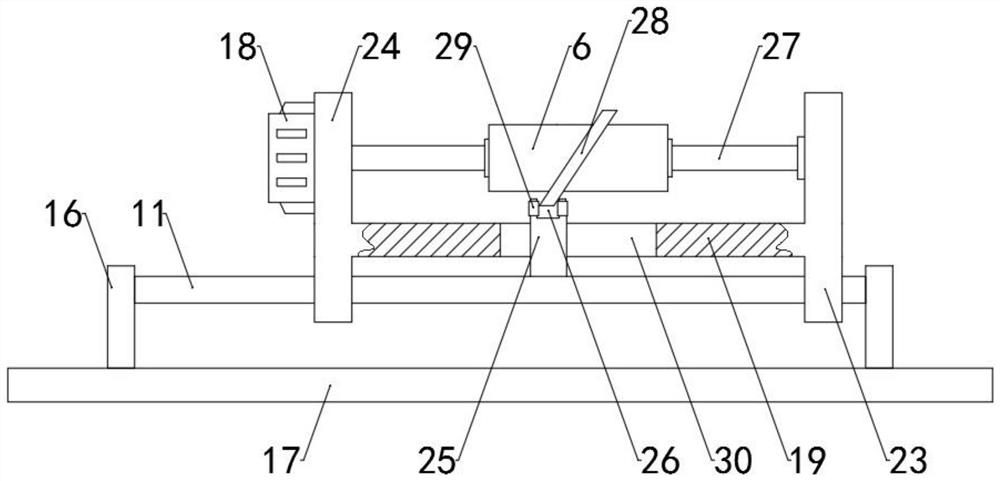

Bar feeding assisting device

ActiveCN105563215AReduce investmentReduce labor intensityAutomatic workpiece supply/removalMetal working apparatusNumerical controlEngineering

The invention discloses a bar feeding assisting device and relates to the technical field of machining. The bar feeding assisting device comprises a lifting device and a jacking mechanism. The lifting device comprises a worktable and a lifting mechanism, a supporting rack is arranged on the worktable, bars to be machined can be erected on the supporting rack, and the lifting mechanism drives the supporting rack to move up and down so that when the bars are lifted to the highest portion, the bars can coincide with the center of a chuck of a numerical control machine tool. By means of the jacking mechanism, the bars can move to the chuck, and the bars can be placed on a feeding bracket in the numerical control machine tool. The bars are matched with the numerical control machine tool through ascending and descending of the worktable and linkage of the jacking mechanism, and the bars can be continuously cut off and discharged for subsequent machining. The bar feeding assisting device has the advantages of being simple and compact in structure, convenient to operate and high in production efficiency, capital investment of special cutting equipment for discharging is reduced, the technological process is simplified, manpower is saved, logistics transfer time between procedures is shortened, and the bar feeding assisting device is particularly suitable for being used in cooperation with the numerical control machine tool and meets the requirement for large-scale production.

Owner:XUZHOU SANHE MACHANICAL PARTS

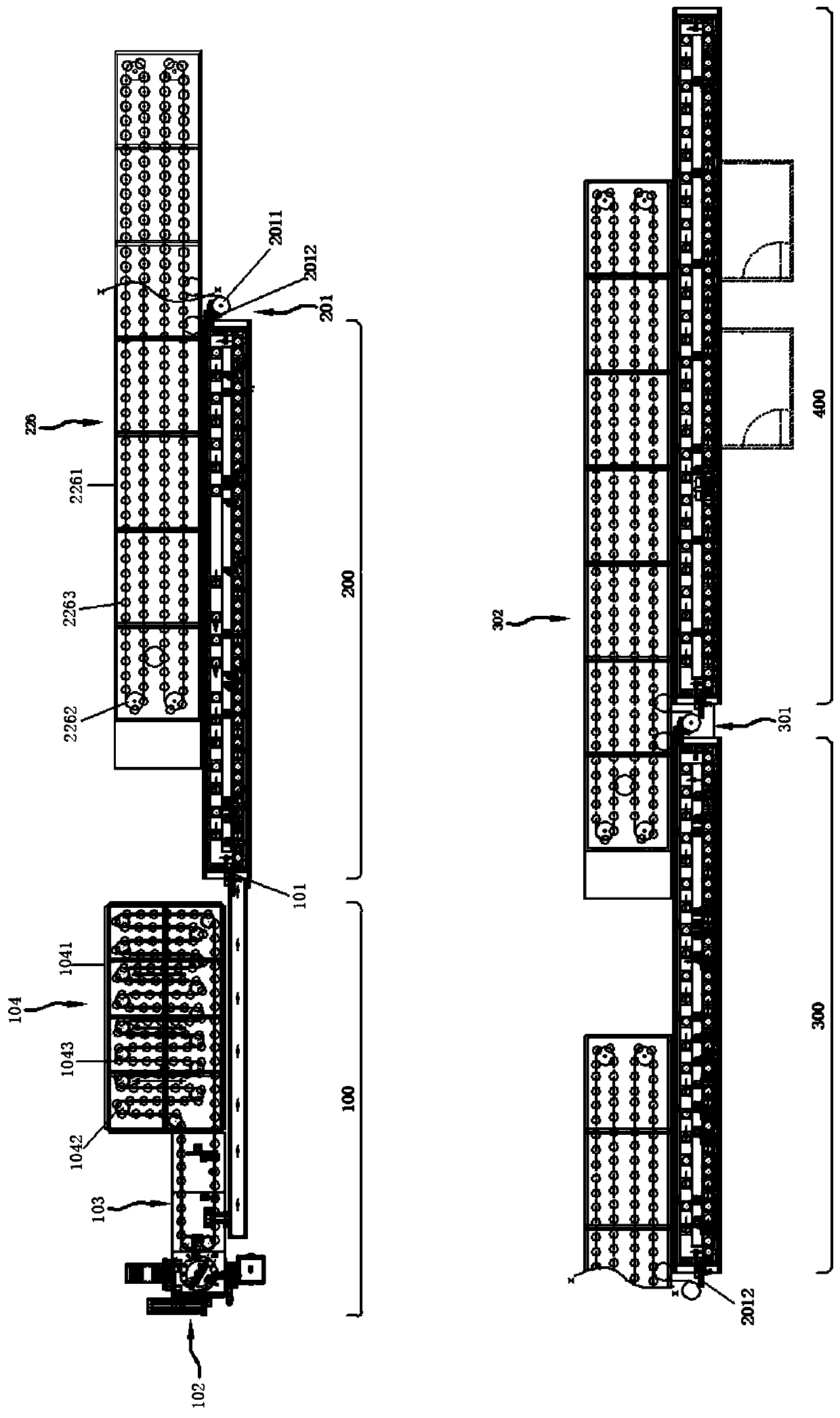

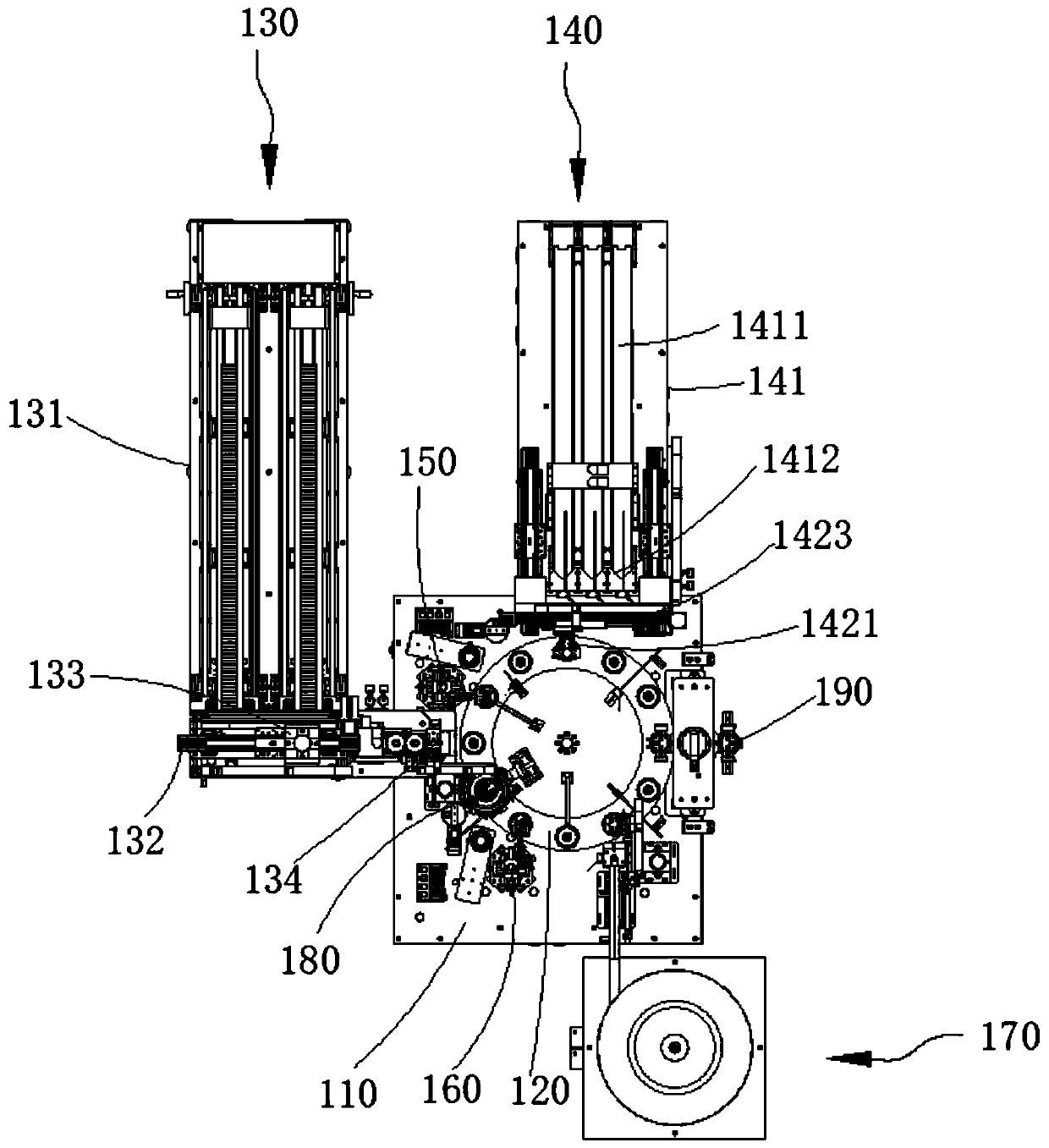

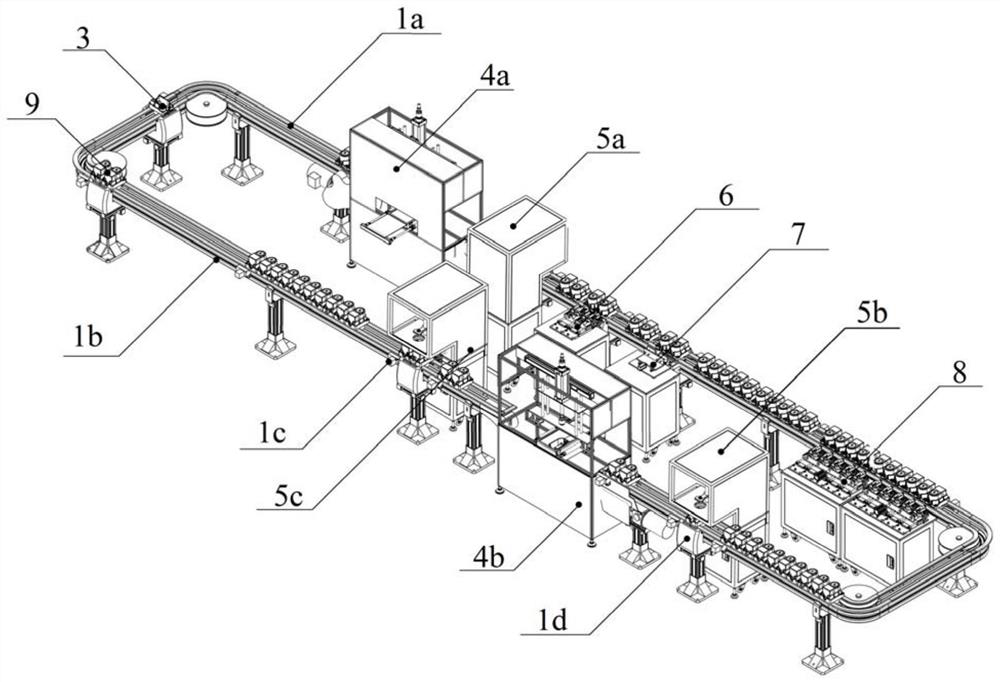

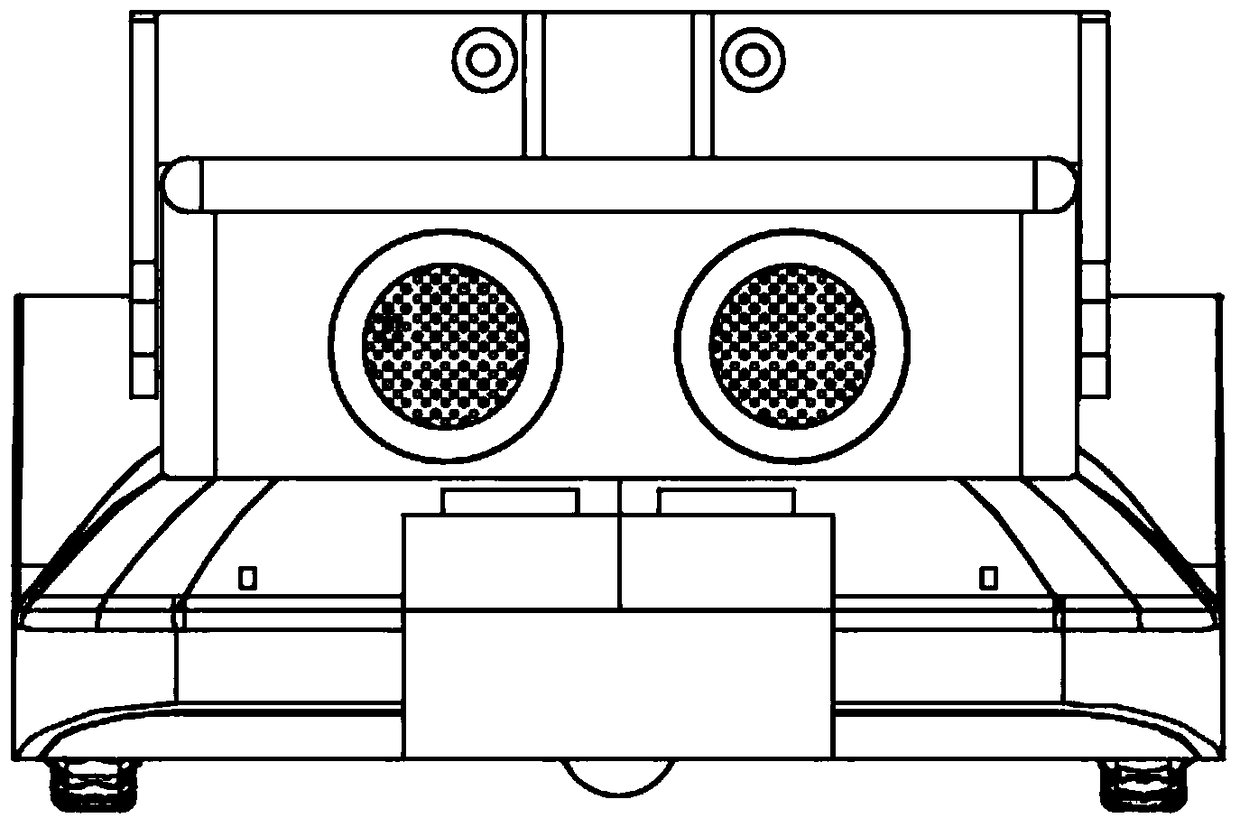

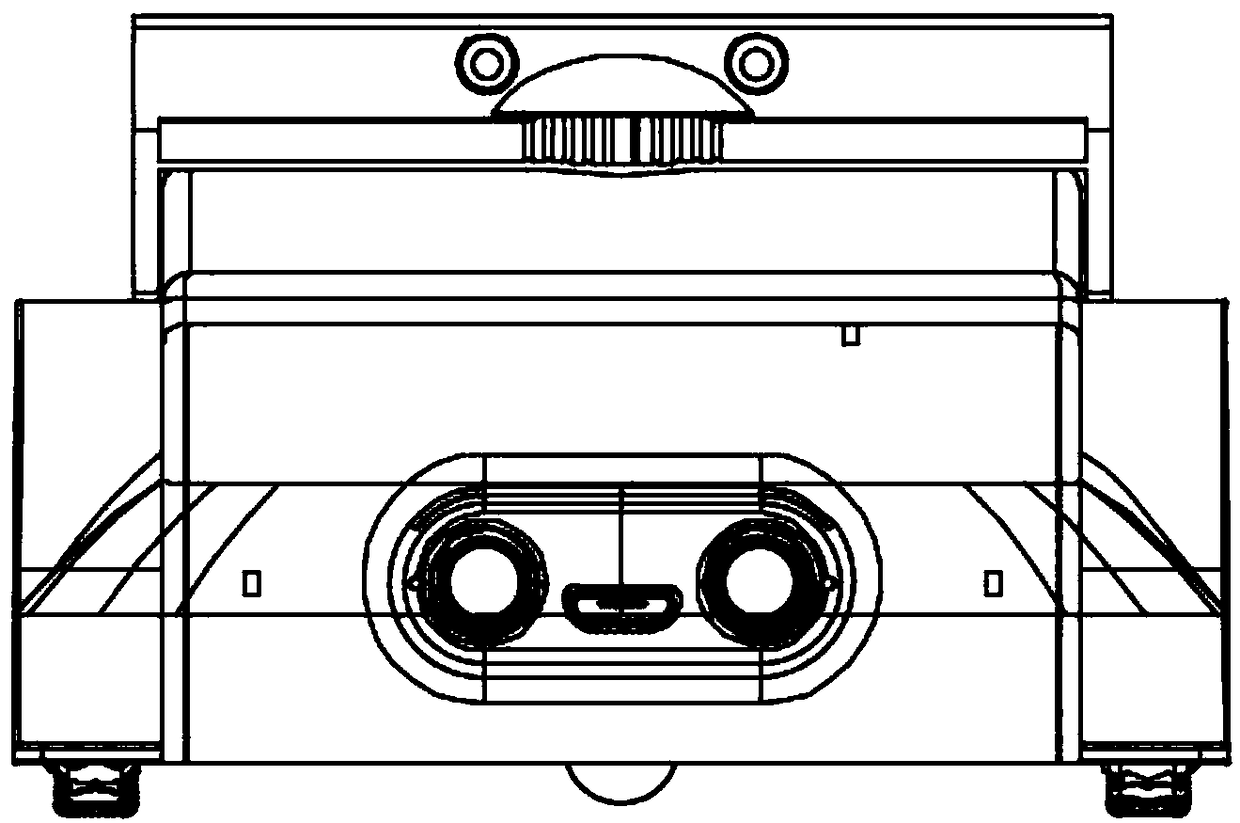

Loudspeaker assembling system

PendingCN110113705AImplement automatic assemblyFully automatedElectrical transducersEngineeringLoudspeaker

The invention relates to the technical field of automation equipment and provides a loudspeaker assembling system which comprises a first assembling section and a second assembling section, wherein the first assembling section comprises a rotary disc, and a plurality of first feeding stations and a plurality of first gluing devices which are arranged along the rotary disc, the rotary disc rotatesto drive the materials to be conveyed, and the first gluing devices are correspondingly arranged at the downstream stations of the first feeding stations respectively; a first assembly assembled on the first assembly section is conveyed to the second assembly section, the second assembly section comprises a conveying device, and a plurality of second feeding stations and a plurality of second gluing devices which are arranged along the conveying device, and all the second gluing devices are correspondingly arranged at the downstream stations of all the second feeding stations respectively. Thefirst assembly section and the second assembly section realize the automatic assembly of a magnetic circuit and a diaphragm of the loudspeaker, realize the automation of assembly, save the manpower,improve the production efficiency and the production quality, contribute to capacity expansion, and adapt to the large-scale production requirements.

Owner:深圳市久巨工业设备有限公司

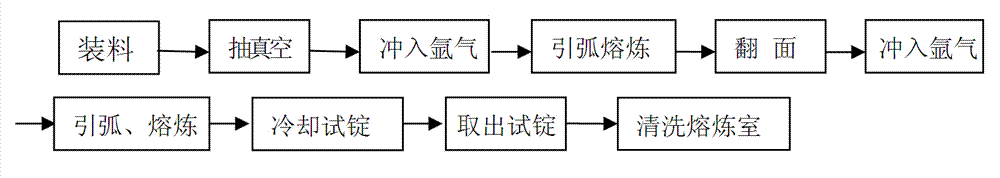

Preparation method of sponge titanium test ingot

InactiveCN102899509AIncrease productivityReduce energy consumptionPreparing sample for investigationVacuum pumpingTest sample

The invention relates to a preparation method of a sponge titanium test ingot. According to the invention, a collected sponge titanium test sample is treated in the technological route of: sample loading, vacuum pumping, smelting, turnover, smelting, cooling, and sampling. The method provided in the invention has the beneficial effects of high production efficiency, low energy consumption and short time, thus being able to adapt to the needs of large-scale production.

Owner:YUNNAN TITANIUM IND

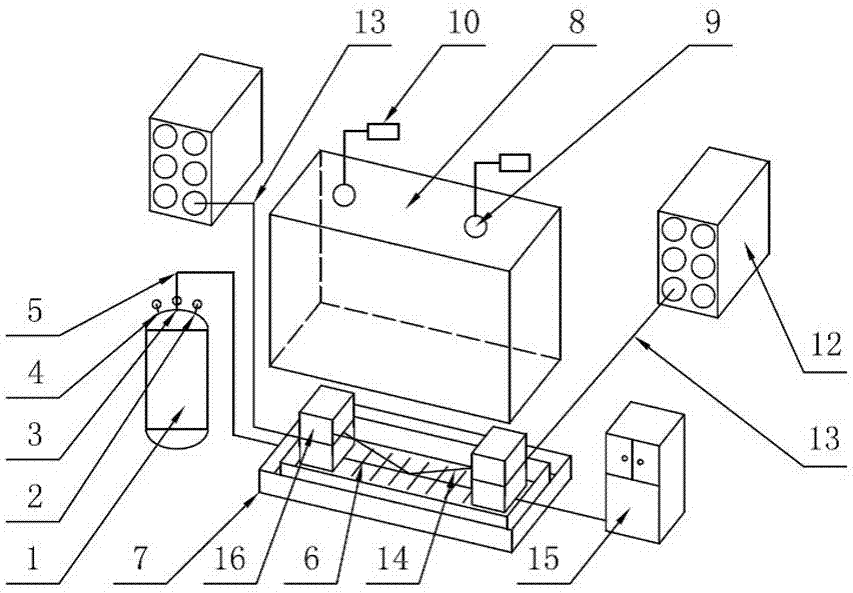

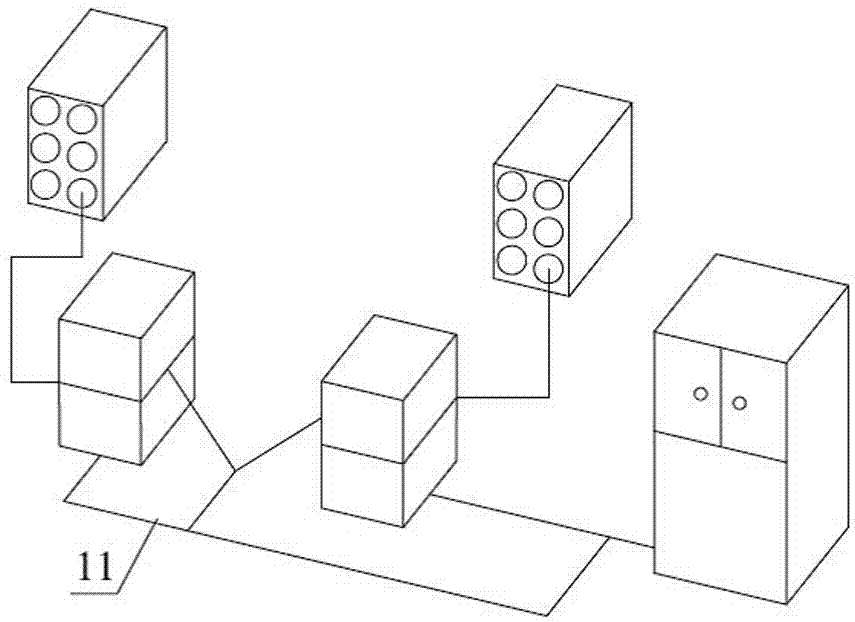

Water-gas dual-sealing heat treatment atmosphere furnace

InactiveCN106978523AFast furnace loadingImprove efficiencyFurnace typesHeat treatment furnacesElectric heatingHeating furnace

The invention discloses a water-gas dual-sealing heat treatment atmosphere furnace. The water-gas dual-sealing heat treatment atmosphere furnace comprises a liquid gas cylinder, a safety valve, an emptying valve, a pressure reducing valve, a hose, a distribution pipe, a water sealing base, a water sealing cover shell, control valves and oxygen amount monitors, and further comprises a gas sealing electric heating atmosphere device; the gas sealing electric heating atmosphere device comprises cylinder bundles, gas conveying pipes, a thermocouple, an electric heating furnace control cabinet, and electric heating furnaces; the cylinder bundles are arranged outside the sealed space formed by the water sealing base and the water sealing cover shell, and connected with the electric heating furnaces through the gas conveying pipes; and the electric heating furnaces are arranged on the water sealing base and connected with one end of the thermocouple, and the other end of the thermocouple is connected with the electric heating furnace control cabinet. Through the water-gas dual-sealing heat treatment atmosphere furnace, the effect that the whole treatment process is in a protective gas atmosphere is ensured, and oxidation of a workpiece in the heat treatment process is effectively and completely eradicated.

Owner:南通万达能源动力科技有限公司

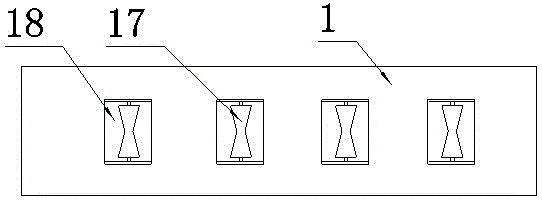

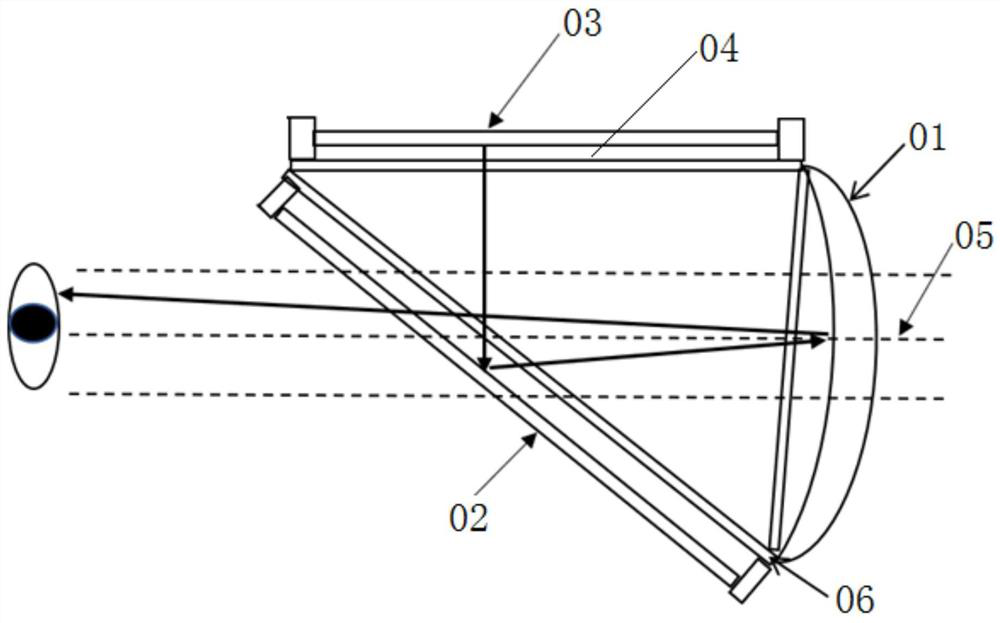

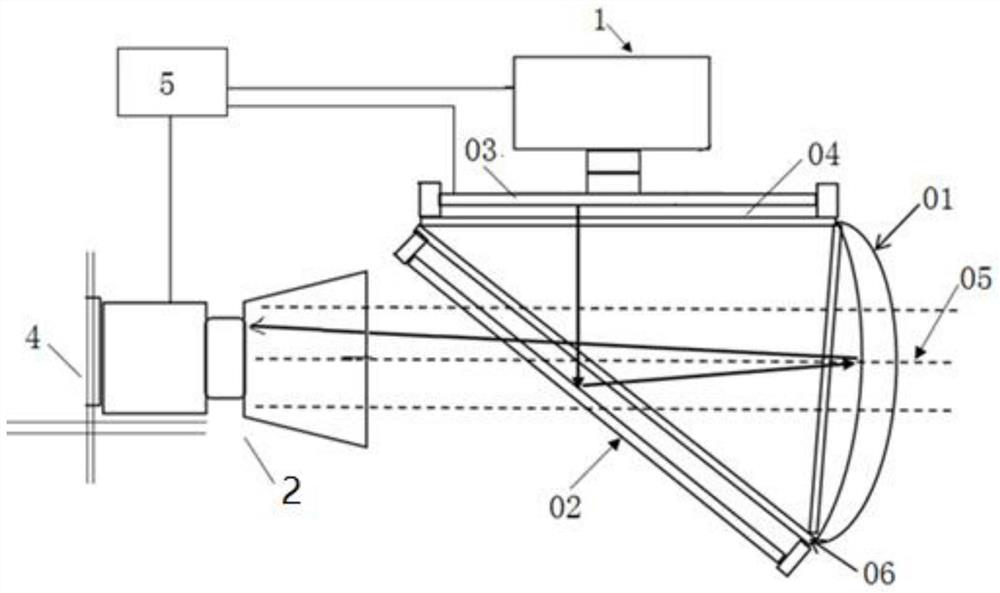

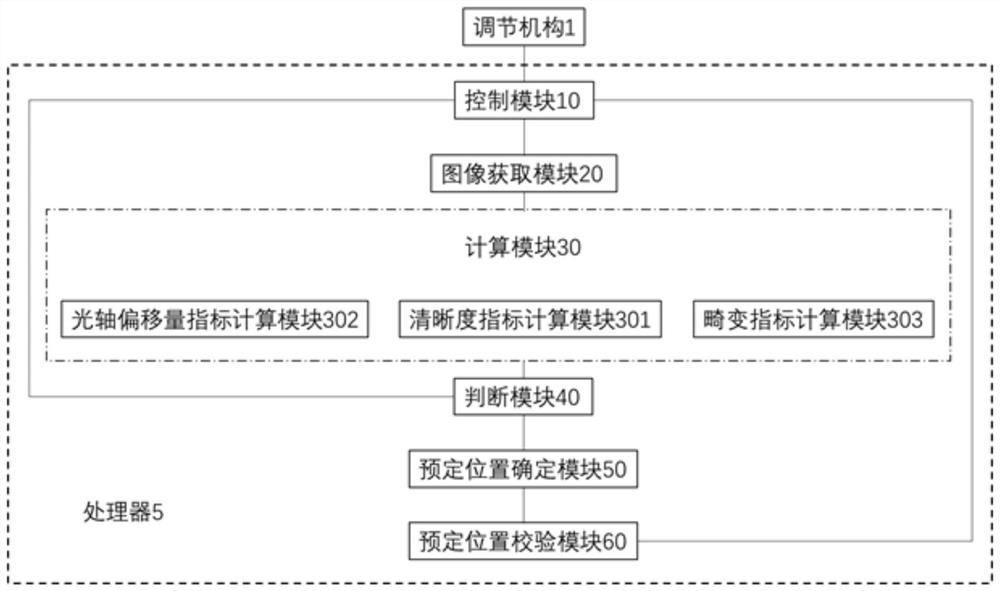

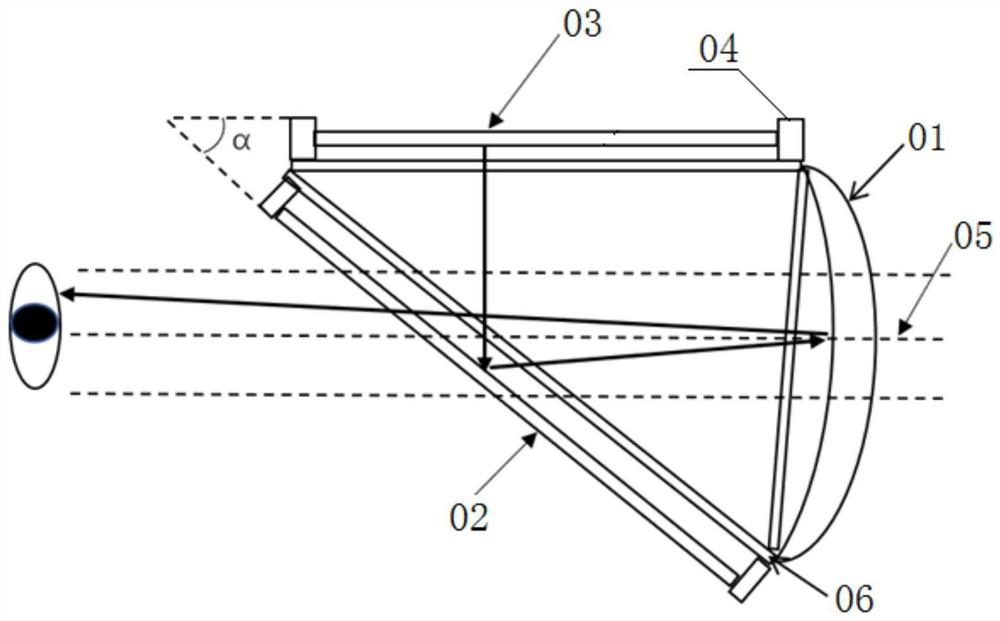

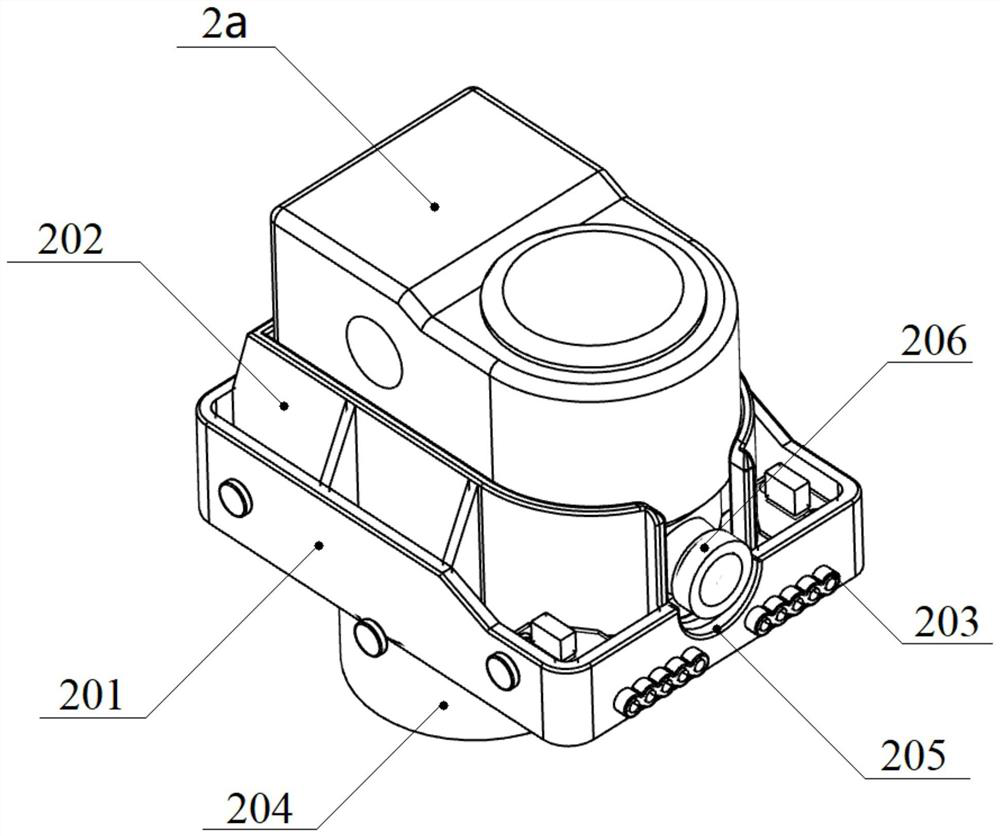

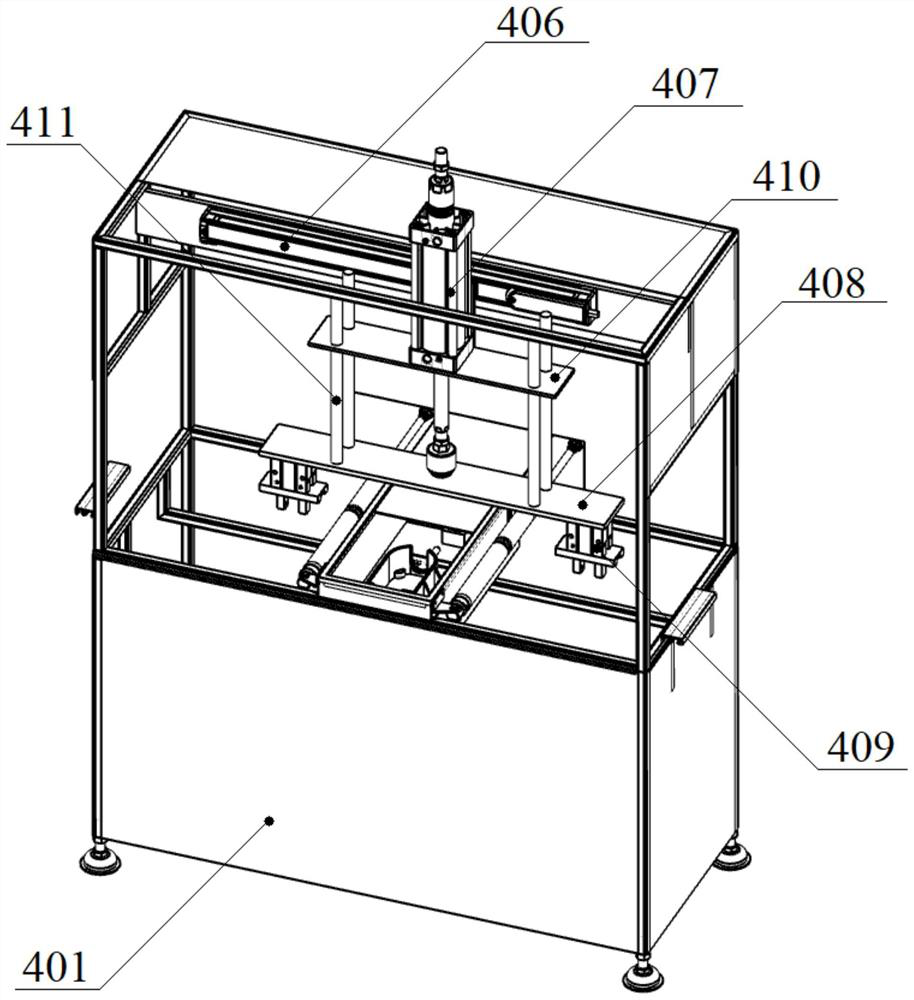

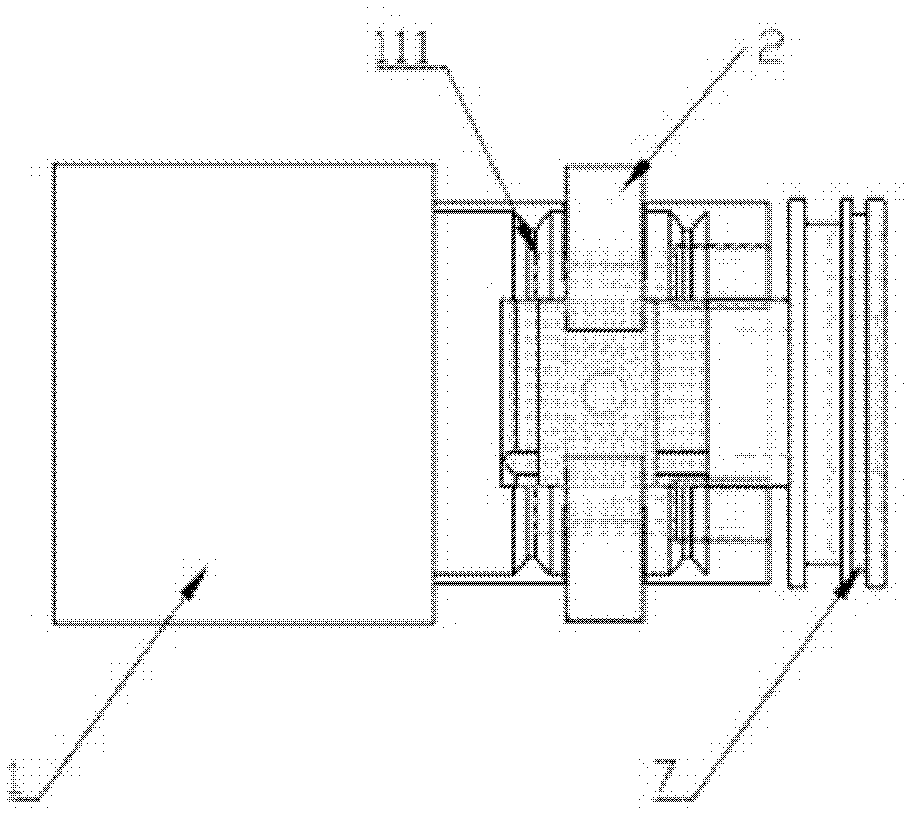

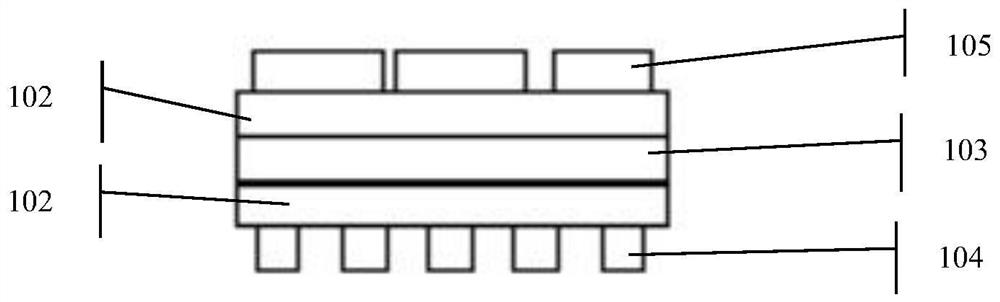

Optical module adjustment test method and device

PendingCN111609995AMeet comfortEnsure consistencyOptical apparatus testingOptical ModuleImaging quality

The invention provides an optical module adjustment test method and device. According to the device, a camera is arranged on an imaging light path of an optical module, so the visual effect of human eyes is simulated; the method comprises acquiring an image of a test legend displayed by a display device in a camera, judging whether the display device reaches a preset position or not according to adefinition index, an optical axis offset index and a distortion index of the acquired test legend image, and adjusting the position of the display device on line until the design requirement of a quality index of the test legend image is met. According to the device, the position of the display device can be adjusted in time according to the quality index of the test legend image shot by the camera, adverse effects of the structural tolerance, the assembly tolerance and the aberration of the optical module on the imaging quality of the optical module are compensated to a certain extent, and the product yield and the assembly efficiency are improved.

Owner:弗提图德萨沃有限公司

Tungsten crucible internal defect detection method

ActiveCN102879470AThe detection process is fastImprove efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesMetallurgyUltrasonic testing

The invention relates to the technical field of ultrasonic flaw detection and particularly to a tungsten crucible internal defect detection method. A phased array ultrasonic detection device is used, a specially-made sensitivity test block with high sensitivity serves as a reference test block, according to structural features of a tungsten crucible product, a tungsten crucible is divided into three parts, optimum phased array configuration is elected for ultrasonic detection, the method can be used in detection of tungsten crucible internal defects within the diameter of 600mm, the height of 700mm and the thickness of 30mm, a tungsten crucible internal defect with the smallest equivalent hole of 0.2mm can be detected, the defect detection can not be missed, one tungsten crucible is detected for about 10 minutes, and the method is simple in operation, high-efficiency, direct in detection result, low in cost and capable of meeting the requirement of large-scale production.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Back edge flanging machine of automobile canopy

The invention relates to a back edge flanging machine of an automobile canopy. An upper worktable and a lower worktable which are parallel to each other are arranged on a machine frame. A locking device is arranged on the lateral surface of the upper worktable; a back edge heating device, a back edge insert device and an elastic press plate are arranged at the bottom of the upper worktable; and a heating block group is arranged below the back edge heating device. A back edge flanging pressing assembly mechanism corresponding to the back edge heating device is arranged on the lower worktable. The back edge flanging machine performs flanging sizing for products through the heating device and the flanging pressing assembly mechanism, can improve production efficiency, reduce labor intensity of workers and save product manufacture cost and energy consumption cost, is simple and compact in structure, reasonable in layout and convenient to operate, can improve product quality, and meets requirements of the automobile industry for volume production.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

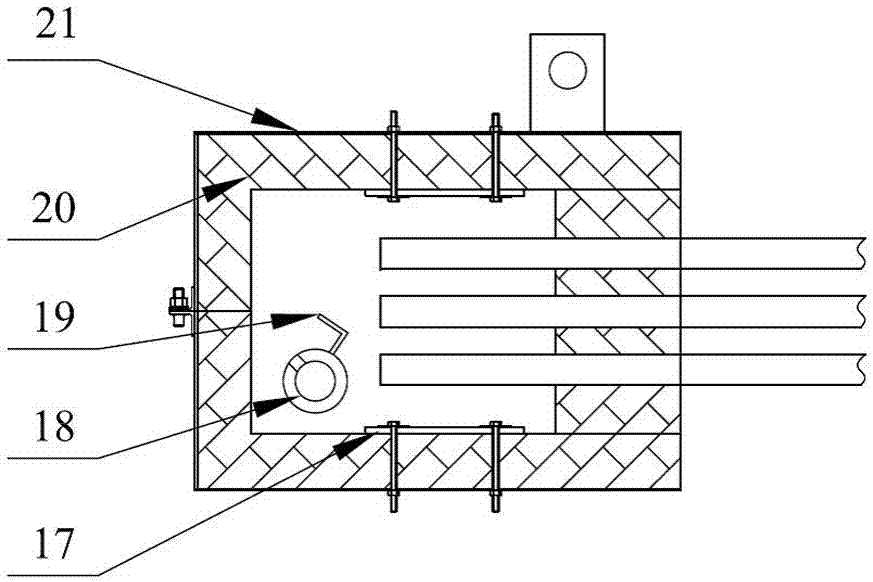

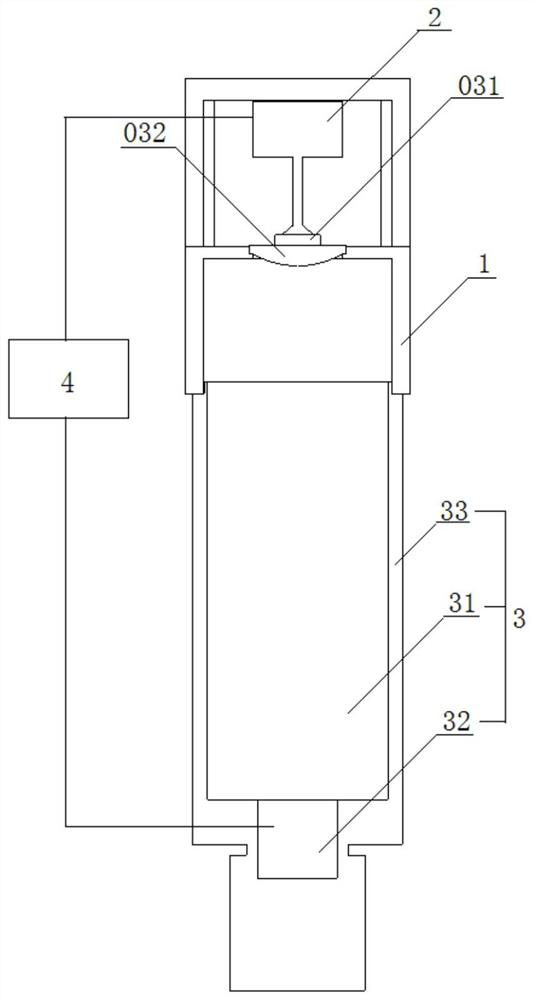

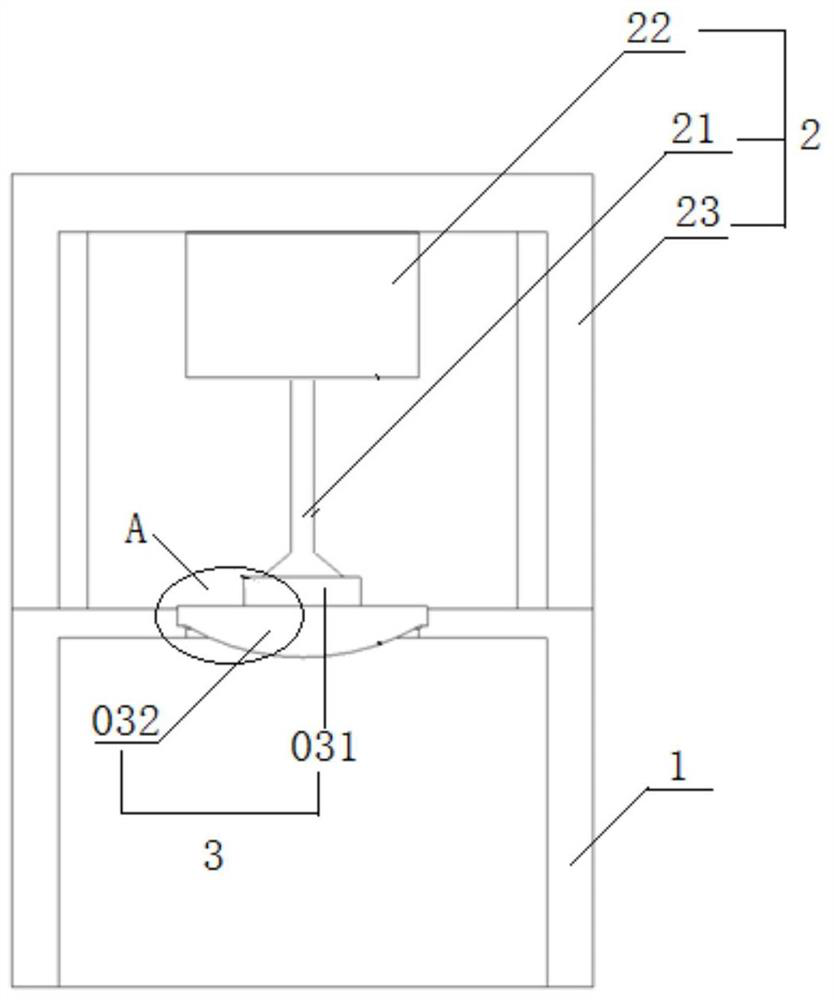

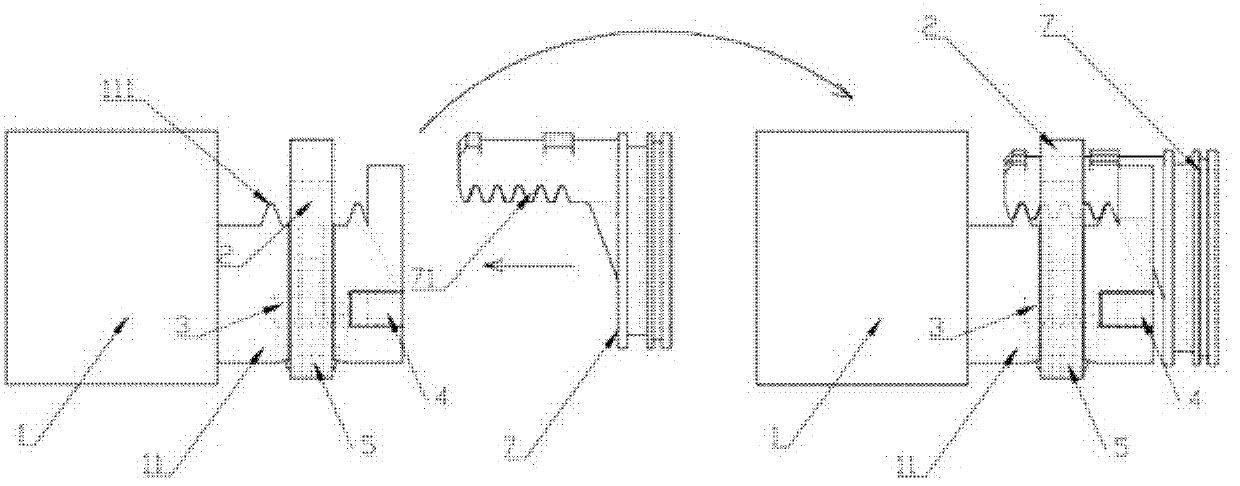

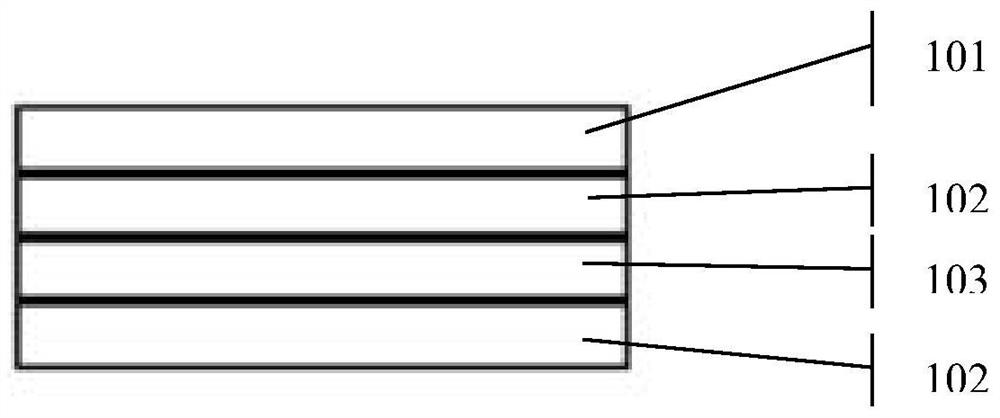

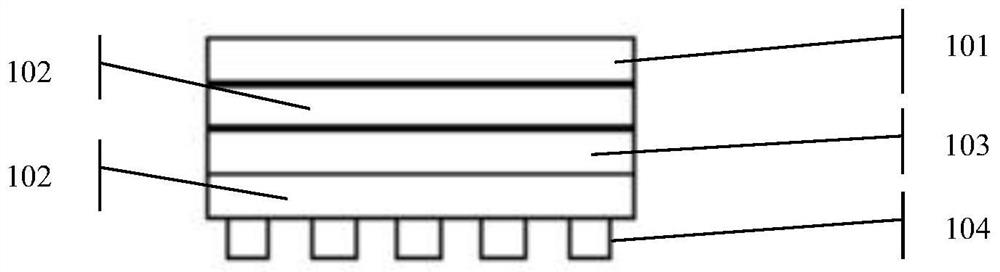

Adjustment system and method for display device in optical module

PendingCN111610636AImprove the efficiency of assembly and adjustmentReduce manufacturing costOptical elementsOptical ModuleOphthalmology

The invention provides an adjustment system and method for a display device in an optical module; the system is provided with an alignment clamp on a reference position and used for clamping a lens ora lens assembly, an adjusting mechanism is used for adjusting the position of a display panel, and the image acquisition device is used for shooting an alignment image of the display panel. The center offset and the angle offset of the actual position and the target position corresponding to the alignment image of the display panel are obtained, the position of the display panel is adjusted through the adjusting mechanism, and therefore the display panel is fixed to the lens or the lens assembly according to the design requirement. By arranging the reference position for clamping the lens orthe lens assembly, the lens or the lens assembly does not need to be calibrated, a temporary fixing mechanism does not need to be assembled and disassembled, only the position of the display panel needs to be adjusted, operation steps are simplified, and assembling and adjusting efficiency is improved; the operating arm of the adjusting mechanism is of a telescopic structure and is provided with an elastic end, so that the production cost and the operation complexity of the tool are simplified, the adjustment precision is improved, and the mass production requirement is met.

Owner:弗提图德萨沃有限公司

Automobile roof frontier flanging machine

InactiveCN102941670AReduce labor intensityReduce consumption costDomestic articlesHigh volume manufacturingEngineering

The present invention relates to an automobile roof frontier flanging machine. A rack is provided with an upper workbench and a lower workbench which are mutually parallel. The side surface of the upper workbench is provided with a locking device. The bottom of the upper workbench is mounted with a frontier heating mold, a frontier blade inserting device and an elastic platen. The lower workbench is mounted with a frontier flanging clamping assembly mechanism corresponding to the frontier heating mold. The frontier flanging machine performs flanging shaping for products through the frontier heating mode and the frontier flanging clamping assembly mechanism, thus the production efficiency is improved, labor intensity of workers is reduced, production cost of the product is saved and energy consumption cost is saved. The frontier flanging machine is simple and compact in structure, reasonable in layout and easy to operate, helps to improve product quality and is applicable to the mass production in the automobile industry.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

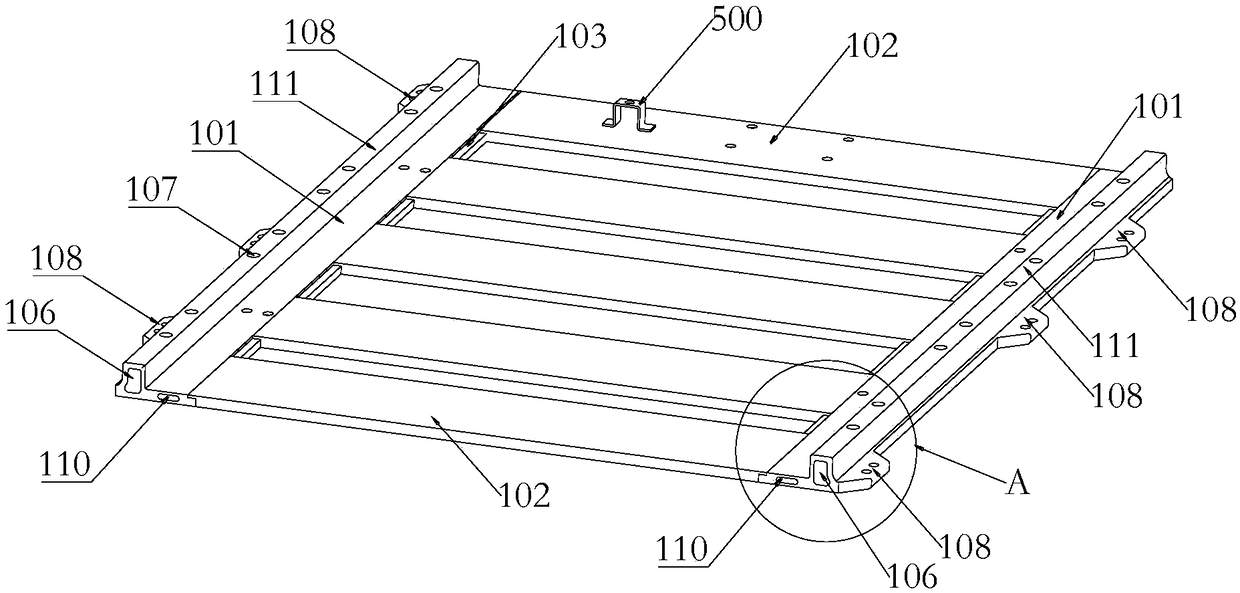

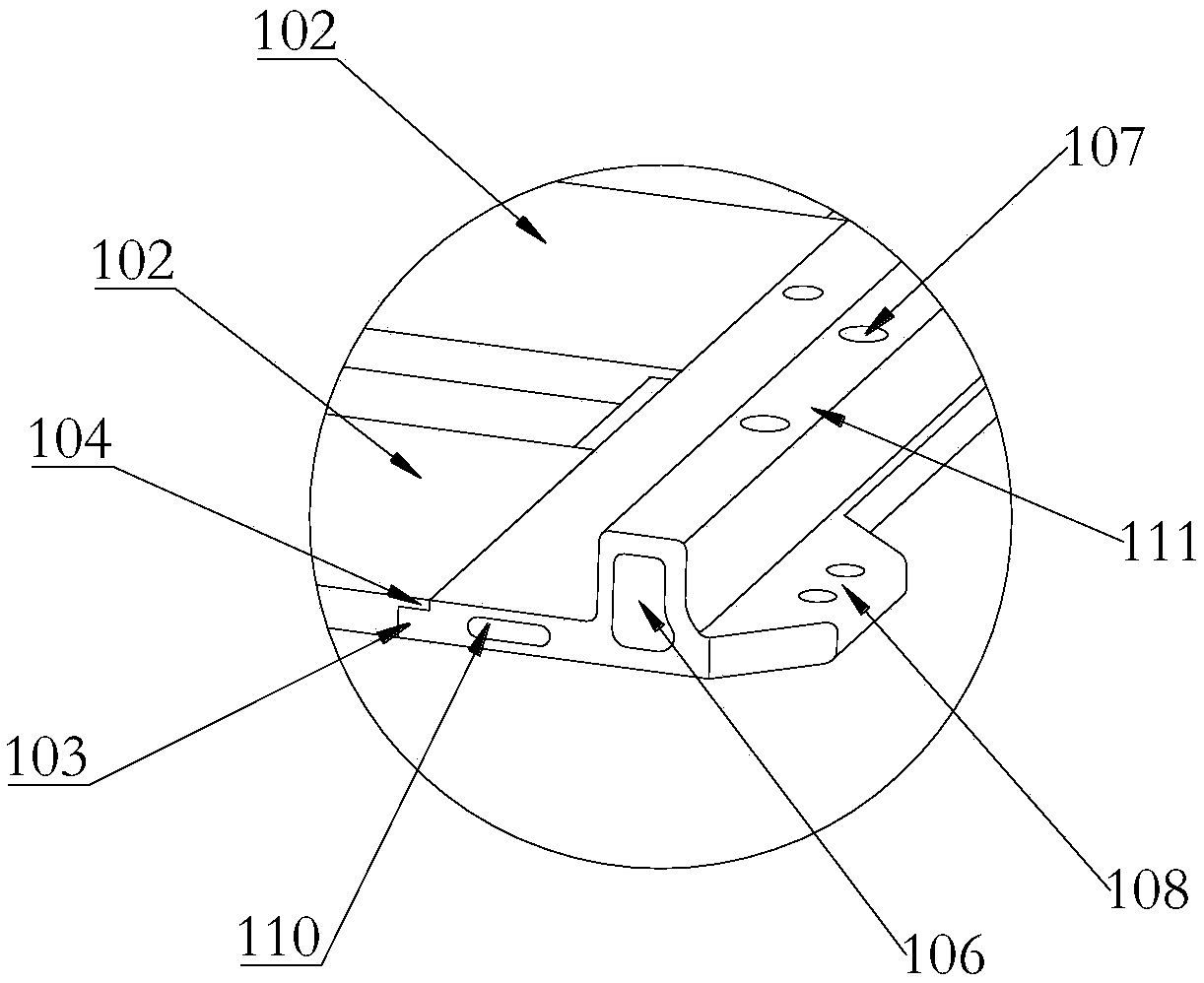

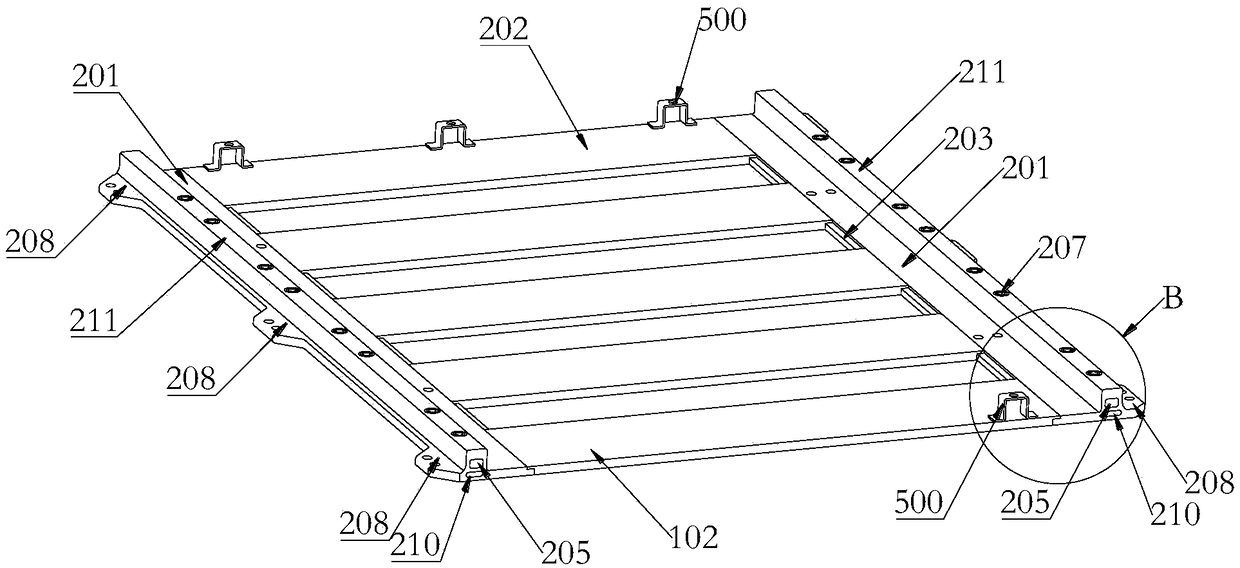

Tailor-welded type aluminum alloy module tray and battery pack

The invention relates to a tailor-welded type aluminum alloy module tray and a battery pack. The tailor-welded aluminum alloy module tray comprises two fixed beams and a plurality of beams; two fixedbeams are arranged in parallel and connected with a battery box body; two ends of each beam are respectively welded on two fixed beams; the fixed beams and the beams are molded through an extrusion mold by adopting aluminum alloy material and are in tailor-welded connection. The tailor-welded type aluminum alloy module tray disclosed by the invention is formed by performing the tailor-welded on the parts molded through the extrusion mold by adopting the aluminum alloy material; the mold is cheap and easy to acquire; the development cots is reduced, the production efficiency is high, the tray can be suitable for the large-scale production demand, and the economic benefit is increased.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

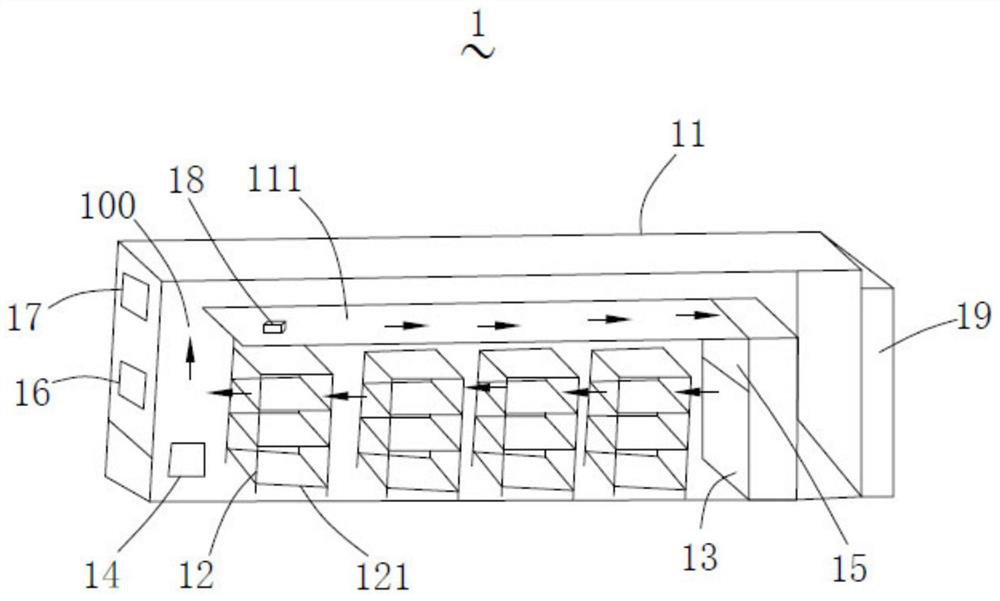

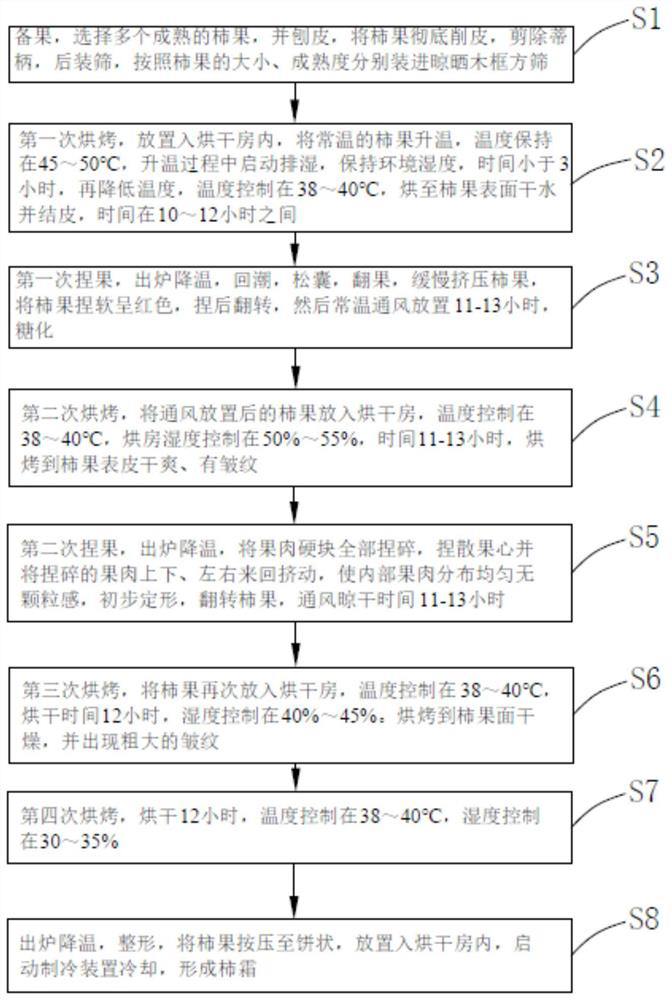

Full-automatic temperature-controlled and humidity-controlled heat pump dried persimmon drying equipment and drying technology

PendingCN112556330AIncrease productivityShorten drying timeFood processingDrying gas arrangementsEngineeringProcess engineering

The invention relates to the field of dried persimmon drying equipment, and particularly discloses full-automatic temperature-controlled and humidity-controlled heat pump dried persimmon drying equipment and a drying technology. A drying room is arranged and used for containing dried persimmons, and the temperature and humidity in the drying room are automatically controlled through a dehumidifierand a drying device so as to provide drying environments under different drying requirements, each drying step in the dried persimmon forming process is completed in the drying room, that is, on thebasis of the full-automatic temperature-controlled and humidity-controlled heat pump dried persimmon drying equipment, the dried persimmon drying process is completed through drying in the equipment and is not influenced by weather and climate in a traditional airing mode, the production efficiency of the dried persimmons is greatly improved, and the large-batch production requirement of the market is met. Meanwhile, by means of the equipment drying mode, the dried persimmon airing time is shortened, and the dried persimmon production efficiency is further improved.

Owner:广西天雨农业科技有限公司

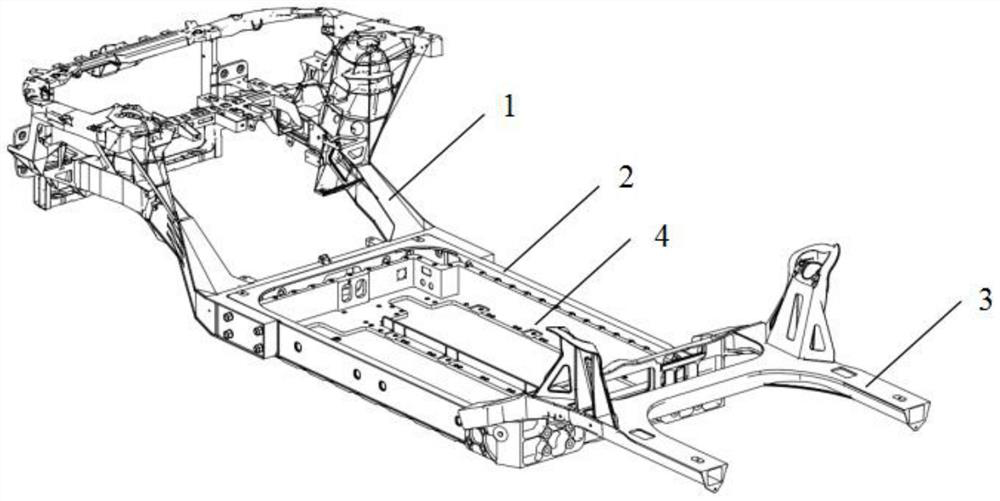

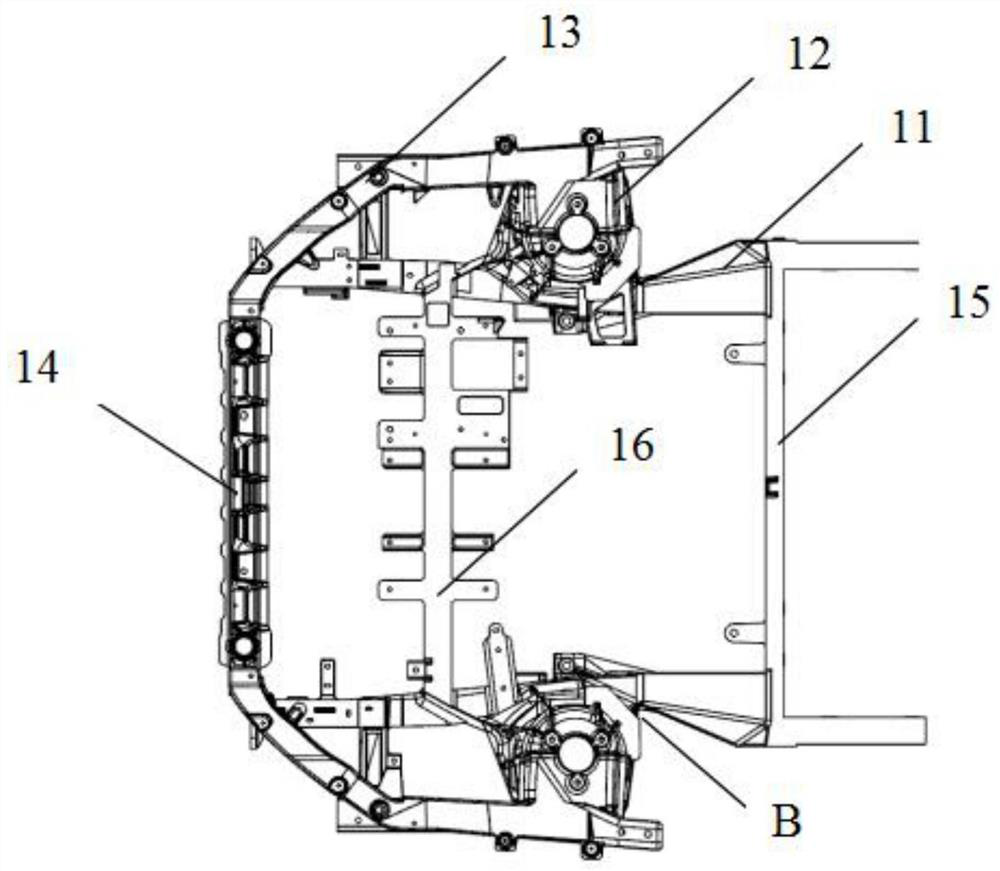

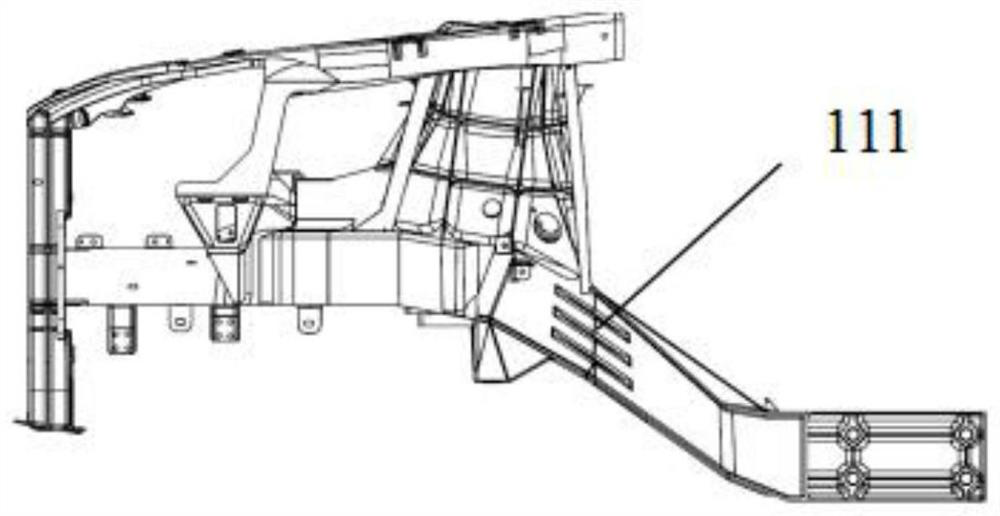

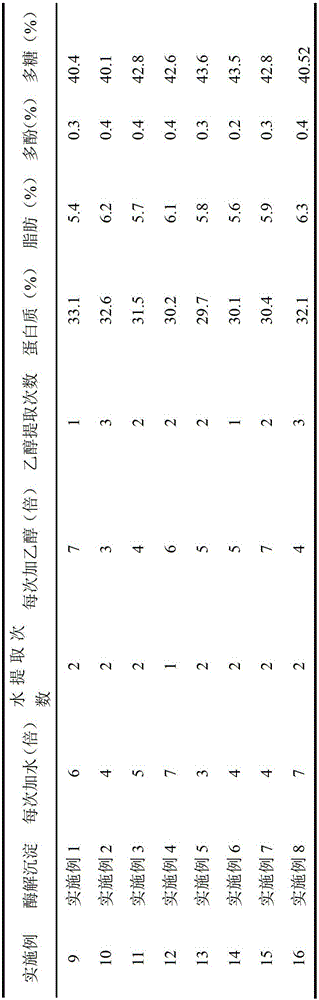

Lower frame of electric vehicle and chassis

PendingCN111746649AAchieve lightweightAchieve integrationElectric propulsion mountingUnderstructuresVehicle frameElectrical battery

The invention discloses a lower frame of an electric vehicle and a chassis using the frame, and relates to the technical field of new energy vehicles. The lower frame comprises a front-end frame, a battery box fixing frame, a rear-end frame and a battery box lower shell, wherein the front-end frame, the battery box fixing frame, the rear-end frame and the battery box lower shell are all thin-wallaluminum alloy pieces; the front-end frame is positioned in front of the battery box fixing frame; the front-end frame is in threaded connection with the front end and the front side edge of the battery box frame through four bolt sets; the rear-end frame is located behind the battery box fixing frame, the rear-end frame is in threaded connection with the rear end and the rear side edge of the battery box frame through four bolt sets, the battery box lower shell is located in the battery box fixing frame, and the battery box lower shell is connected with the battery box frame through a circleof screws at the bottom. The lower frame has the characteristics of no need of welding, simple process, high precision, light weight, high structural strength and modular assembly, and can adapt to small-batch or customized production of electric vehicles.

Owner:SUSHI PRECISION MFG TECH BEIJING CO LTD

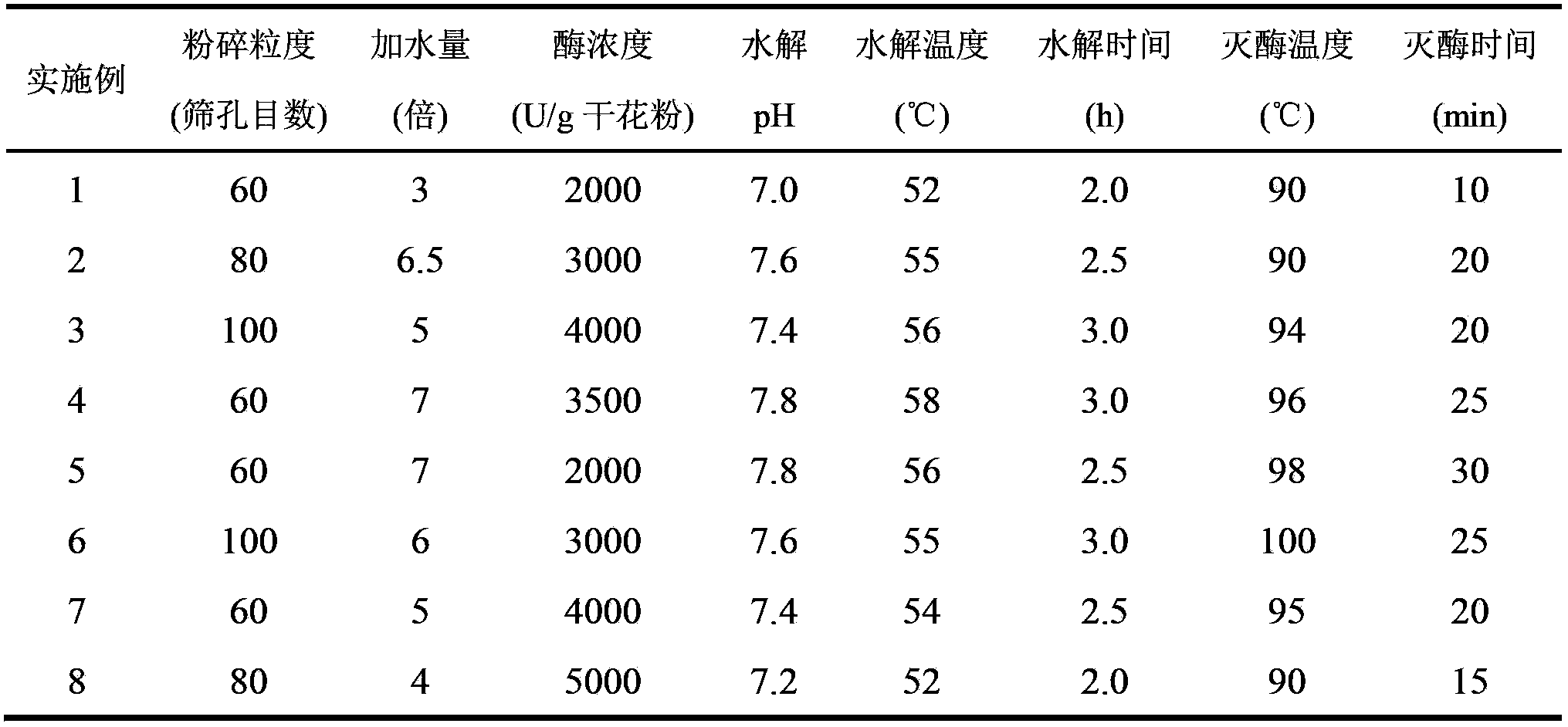

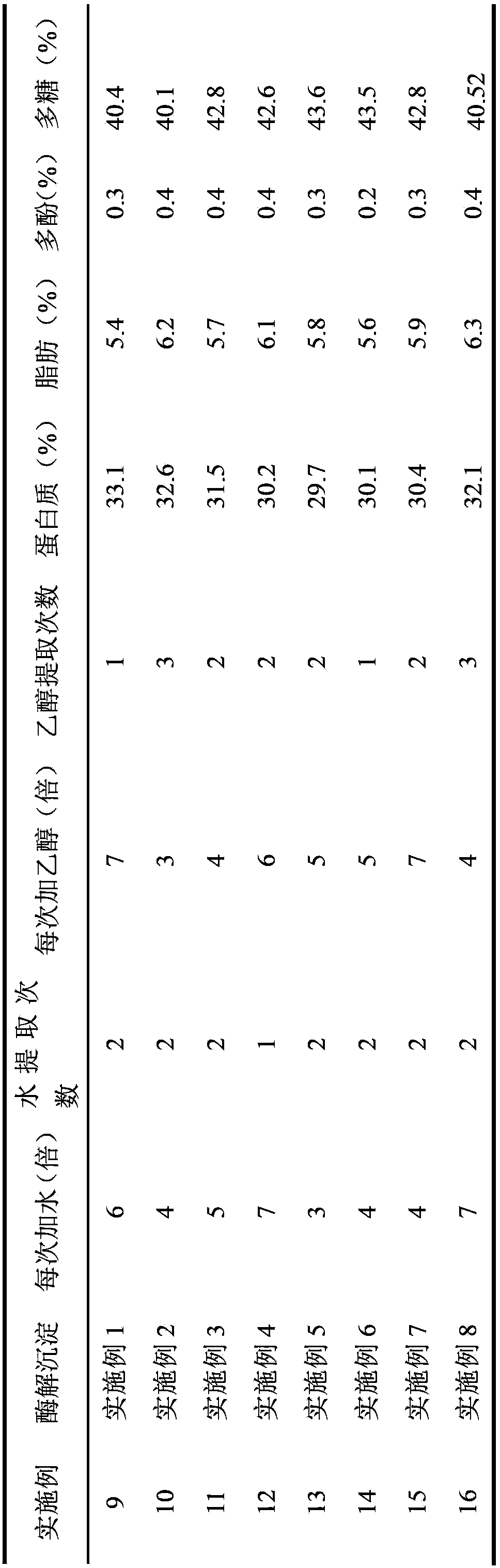

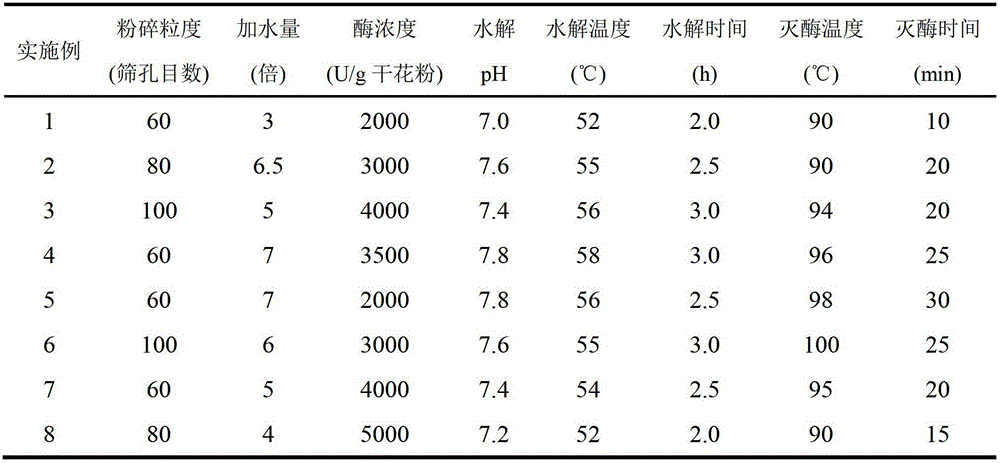

Solid beverage prepared from pollen soluble extracts

ActiveCN103535835AHigh extraction rateImprove solubilityFood ingredient functionsFood preparationPollenSugar

The invention provides a solid beverage prepared from soluble component extracts obtained from pollen, which comprises the following raw materials in percentage by weight: 5-30% of pollen soluble component extracts and 70-95% of auxiliary materials, wherein the pollen soluble component extracts contain 29.7-33.1% of proteins, 5.4-6.3% of fatty substances, 0.2-0.4% of polyphenol and 40.1-43.6% of total sugar. The prepared solid beverage contains abundant nutritional components and is high in effective component content.

Owner:北京世纪京纯蜂产品有限责任公司

Polyurethane lightweight resin plate curing agent for cutting by diamond wire as well as preparation method and application

The invention discloses a polyurethane lightweight resin plate curing agent for cutting by a diamond wire. The polyurethane lightweight resin plate curing agent is prepared from diphenyl-methane-diisocyanate (MDI), polyphenyl polymethylene polyisocyanate and hollow glass microspheres. A preparation method of the polyurethane lightweight resin plate curing agent for cutting by the diamond wire comprises the following steps: putting the diphenyl-methane-diisocyanate and the polyphenyl polymethylene polyisocyanate into a reaction kettle in parts by weight and sufficiently stirring; adding the hollow glass microspheres into the reaction kettle in parts by weight and continually stirring to obtain the polyurethane lightweight resin plate curing agent for cutting by the diamond wire. According to the method disclosed by the invention, the hollow glass microspheres with a proper ratio are added into the MDI to prepare the polyurethane lightweight resin plate curing agent so that the rigidity and strength of a polyurethane resin plate can be improved better; the polyurethane lightweight resin plate prepared from the polyurethane lightweight resin plate curing agent for cutting by the diamond wire is a closed-cell foamed polyurethane lightweight resin plate and has light weight; the distribution of net-shaped structures and the rigidity and strength is more uniform.

Owner:广西珀源新材料有限公司

Device for grinding groove of aluminum alloy profile

PendingCN113370034ARealize automatic grinding processReduce laborGrinding carriagesGrinding drivesElectric machineryGrinding

Owner:湖南千源铝业有限公司

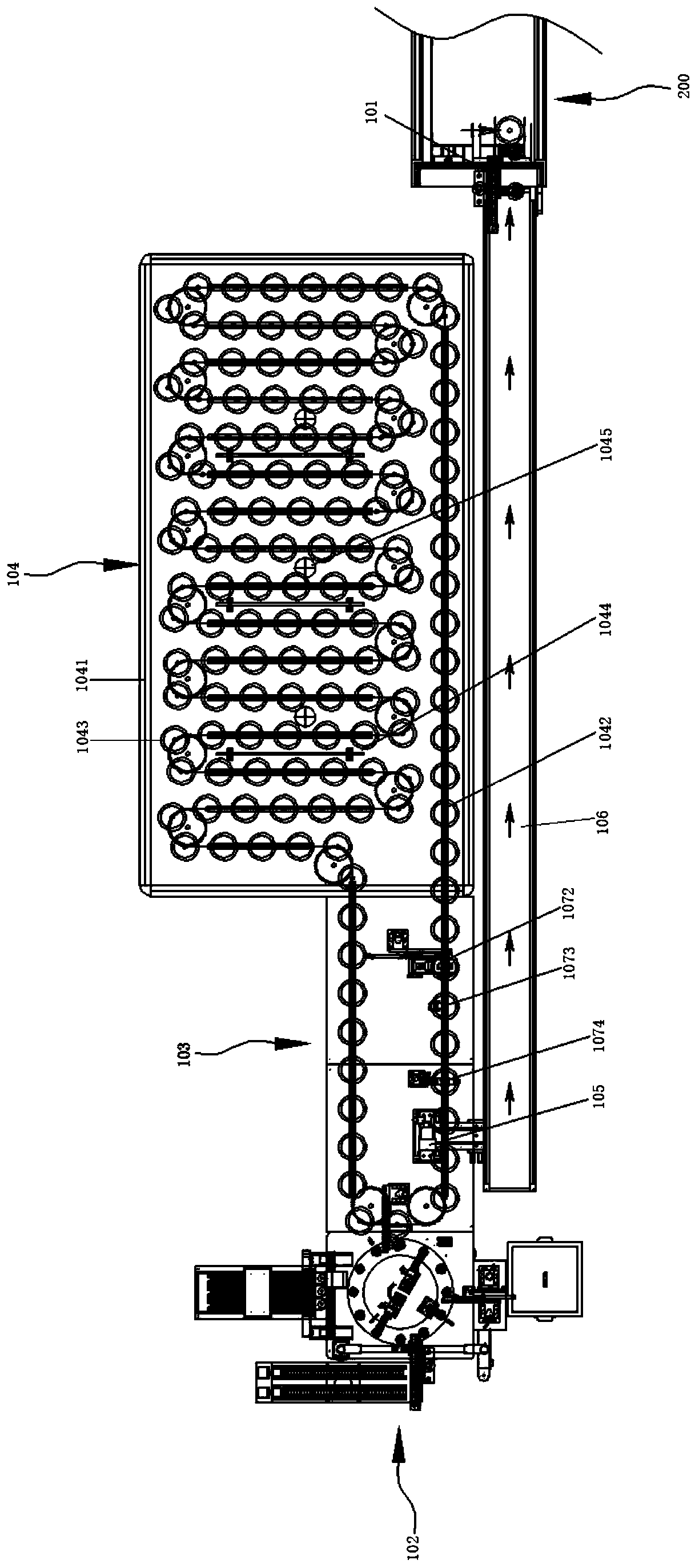

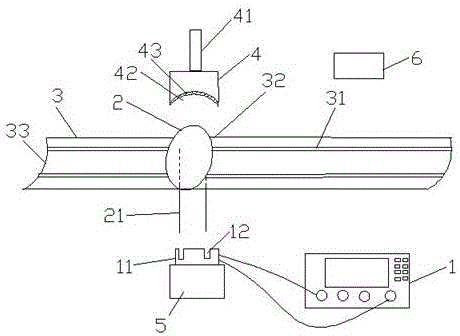

Water meter detection pipeline

ActiveCN111854896BAutomate performance testingEffectively provide detection efficiencyImage analysisCo-operative working arrangementsVisual inspectionEngineering

The invention provides a water meter detection assembly line, comprising: a water meter conveying line, a test system overhead track, a fixed track, a plurality of blocking mechanisms, and a plurality of jacking mechanisms, wherein a plurality of water meter trays are arranged on the overhead track, and the water meter The tray is used to place the water meter, and the water meter conveying line is sequentially provided with a water meter on-line and scanning associated unit, a first wireless shielding unit, a first visual detection unit, a static current test unit, a card swipe detection unit, an electromechanical conversion unit, and a second visual inspection unit. Detection unit, second wireless shielding unit, third visual detection unit, water meter offline unit. The invention has reasonable structural design and smooth operation, can automatically realize multiple performance tests of the water meter and record the detection data, can effectively improve the detection efficiency of the water meter, and can meet the needs of large-scale production.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Disc type high-voltage ceramic dielectric capacitor capacitance value online automatic measurement system

InactiveCN105974204AHigh degree of automationImprove detection efficiencyCapacitance measurementsCapacitanceHorizontal transmission

The invention discloses a disc type high-voltage ceramic dielectric capacitor capacitance value online automatic measurement system. The system comprises a capacitance detector, a horizontal transmission track, a pressure strip, a lifting-up bench and an unqualified product box, wherein the capacitance detector comprises a detection tool, and the detection tool is provided with two plug wire grooves; the upper surface of the horizontal transmission track is provided with a first concave-surface arc; the first concave-surface arc is internally provided with a lead wire transmission groove; the horizontal transmission track is provided with a capacitance detection work station; the pressure strip is arranged right above the capacitance detection work station, the height of the pressure strip can be elevated, and the angle can be rotated; the bottom of the pressure strip is provided with a second concave-surface arc capable of cooperating with the top portion of a ceramic capacitor, and the second concave-surface arc is internally provided with an electromagnet; the lifting-up bench is arranged right below the capacitance detection work station and is coaxially arranged with the pressure strip; and the detection tool is fixedly arranged at the top portion of the lifting-up bench. By use of such a structure, the automation degree is high, the labor intensity is small, the labor cost is low, the detection efficiency is high, and the system can be adapted to the need of batch production.

Owner:WUJIANG JIA BILLION ELECTRONICS TECH

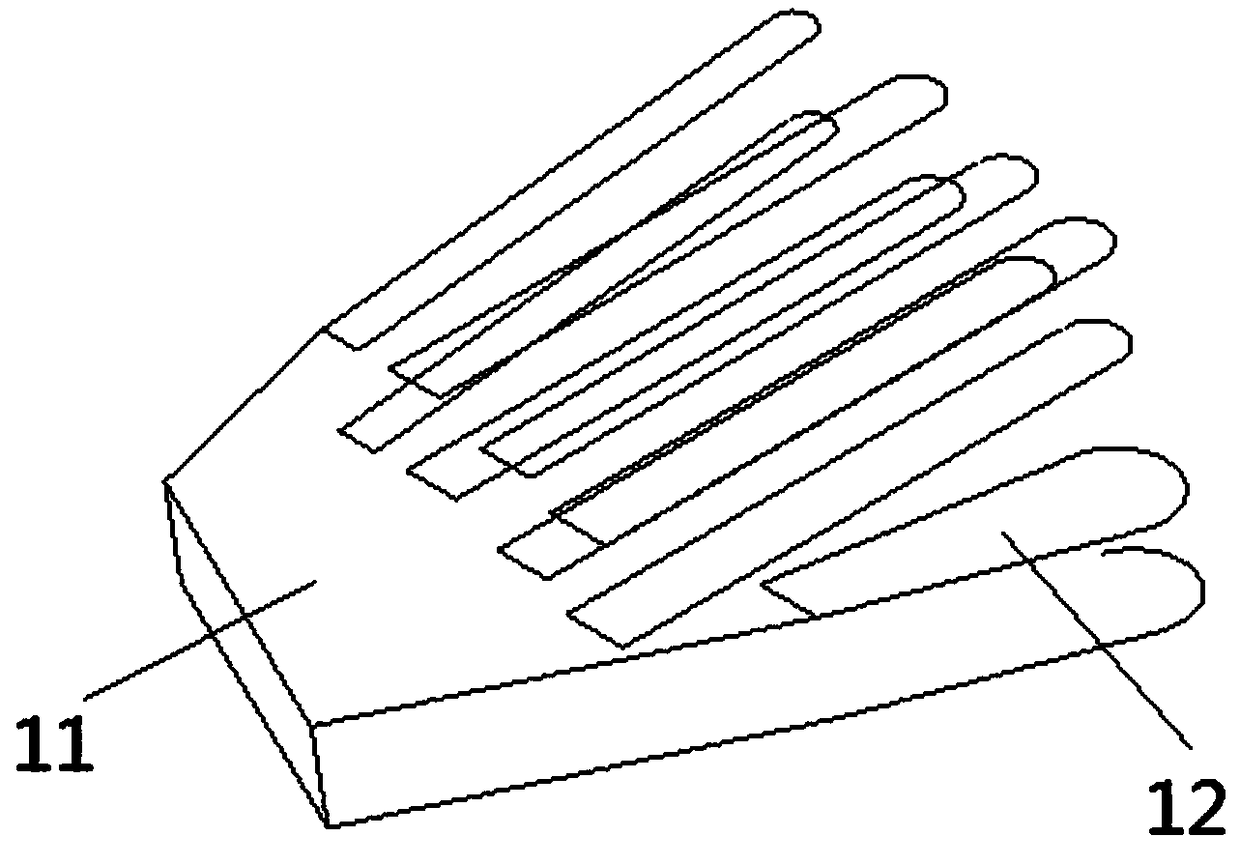

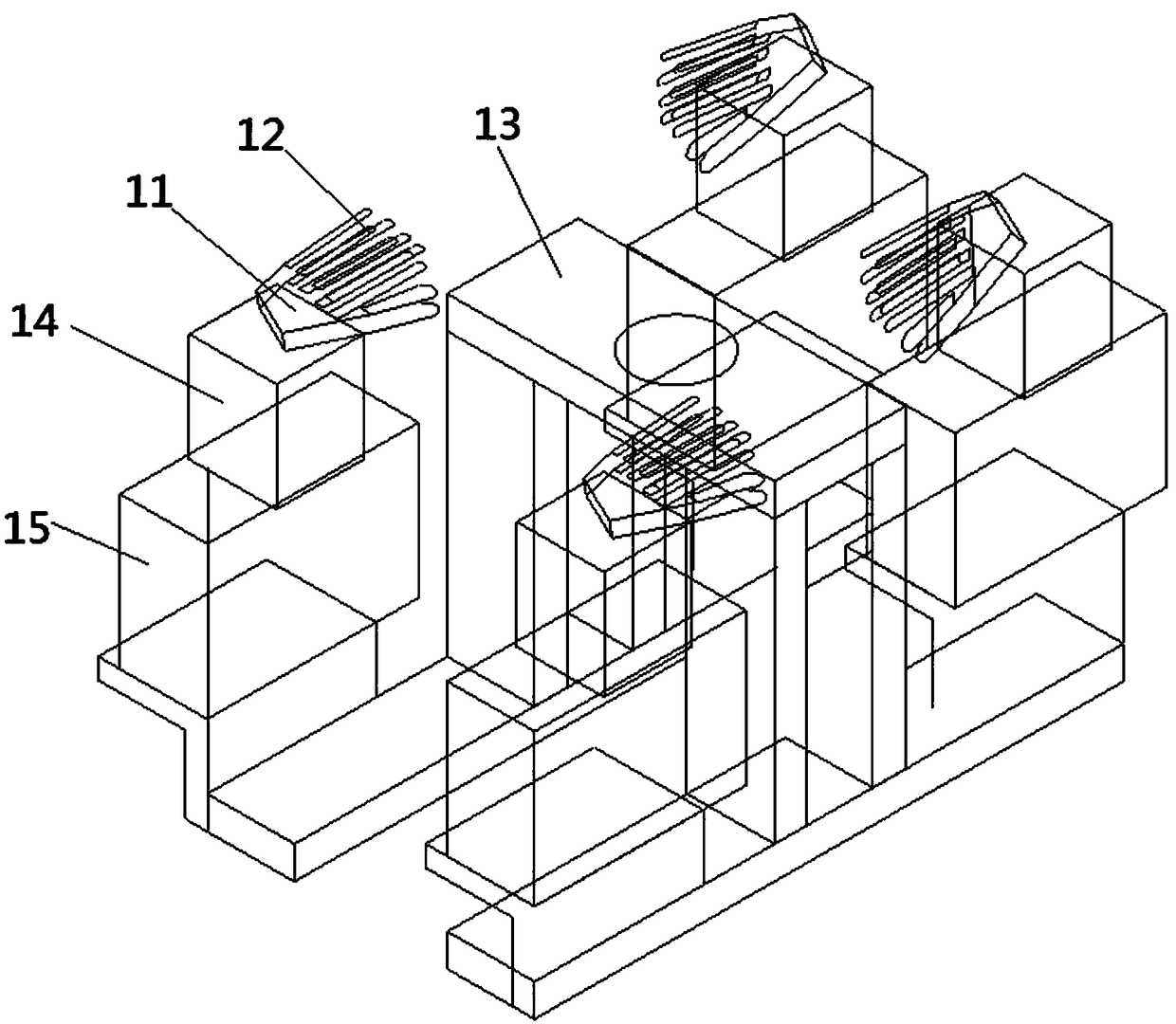

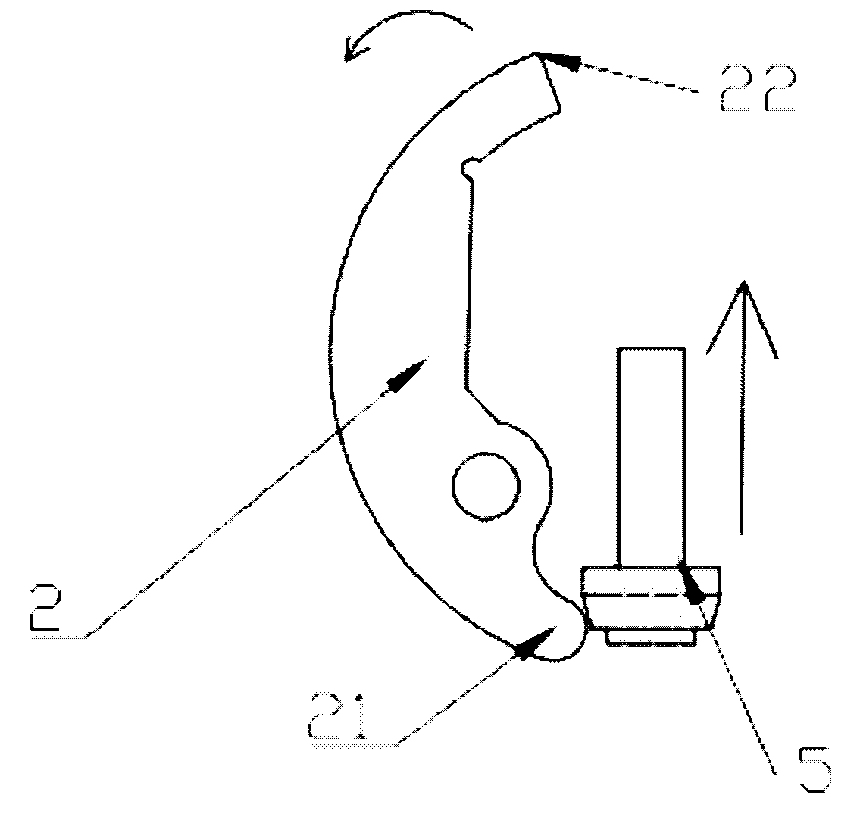

Shoe sole pressing profiling hand, shoe sole clamping device and full-automatic shoe sole grinding machine

PendingCN108908106ARealize fully automatic processingQuality assuranceShoemaking devicesGrinding feedersManipulatorEngineering

Provided are a shoe sole pressing profiling hand, a shoe sole clamping device and a full-automatic shoe sole grinding machine. The full-automatic shoe sole grinding machine comprises a rack, a shoe sole conveying belt, a shoe sole feeding manipulator, a shoe sole clamping device, a shoe sole moving mechanism and a shoe sole grinding device, wherein the shoe sole clamping device comprises a base plate, the shoe sole pressing profiling hand, a motor and a vertical driving module, the shoe sole pressing profiling hand comprises a base block and a plurality of pressing strips, and the multiple pressing strips are sequentially distributed and arranged along one side of the base block and are not located in the same plane. The pressing strips on the base block are not located in the same plane,the pressing strips can adapt to the surfaces different in height of shoe soles and can better fit with the appearances of the shoe soles, so that the shoe sole pressing profiling hand presses shoe soles more firmly and reliably, is stable and durable and facilitates grinding.

Owner:钟志阳

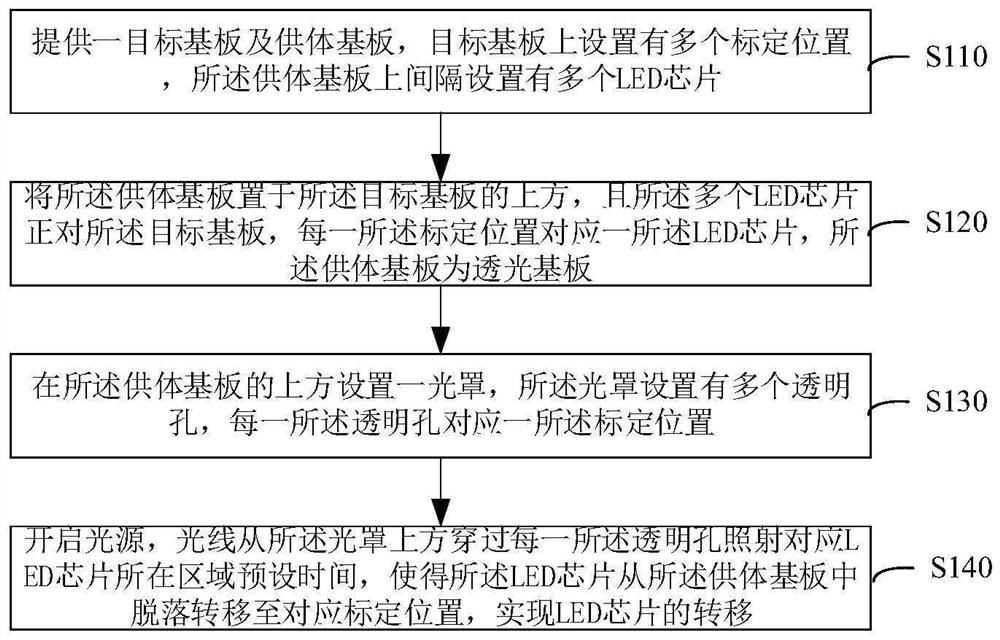

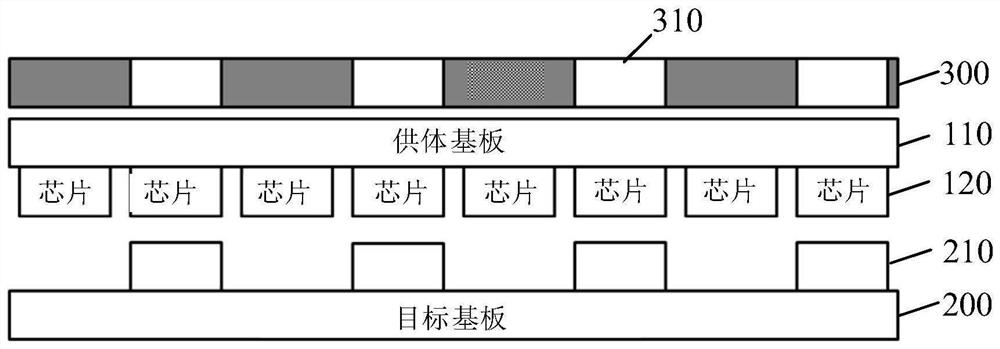

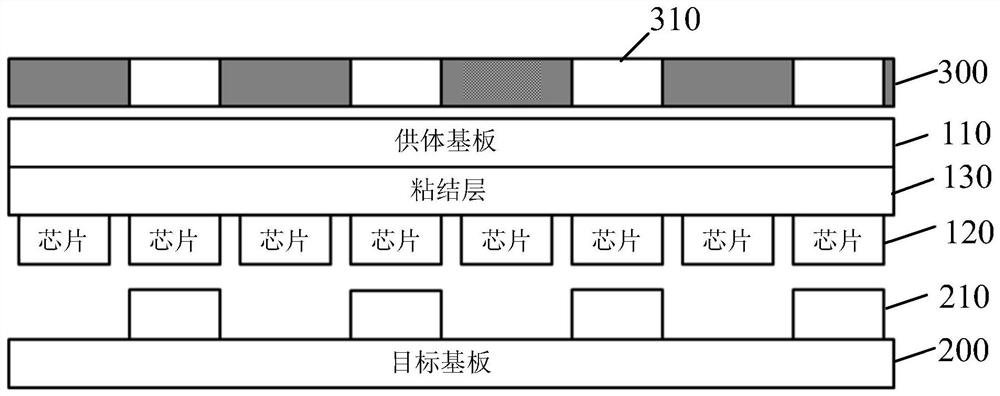

LED chip transfer method

ActiveCN113130348AAdapt to mass production needsSolid-state devicesSemiconductor/solid-state device manufacturingMiniaturizationEngineering

The invention discloses an LED chip transfer method. A donor substrate which is transparent to light rays is arranged, the light rays are incident through light holes which are formed in a light cover in an array mode, after the donor substrate absorbs the light rays, LED chips which correspond to the light holes in a one-to-one mode fall off and are transferred to a target substrate, and the transfer mode is not affected by the sizes of the LED chips; and batch small-sized LED chip transfer can be efficiently and simply realized, and the batch production requirement of display equipment can be met without limitation.

Owner:TCL CORPORATION

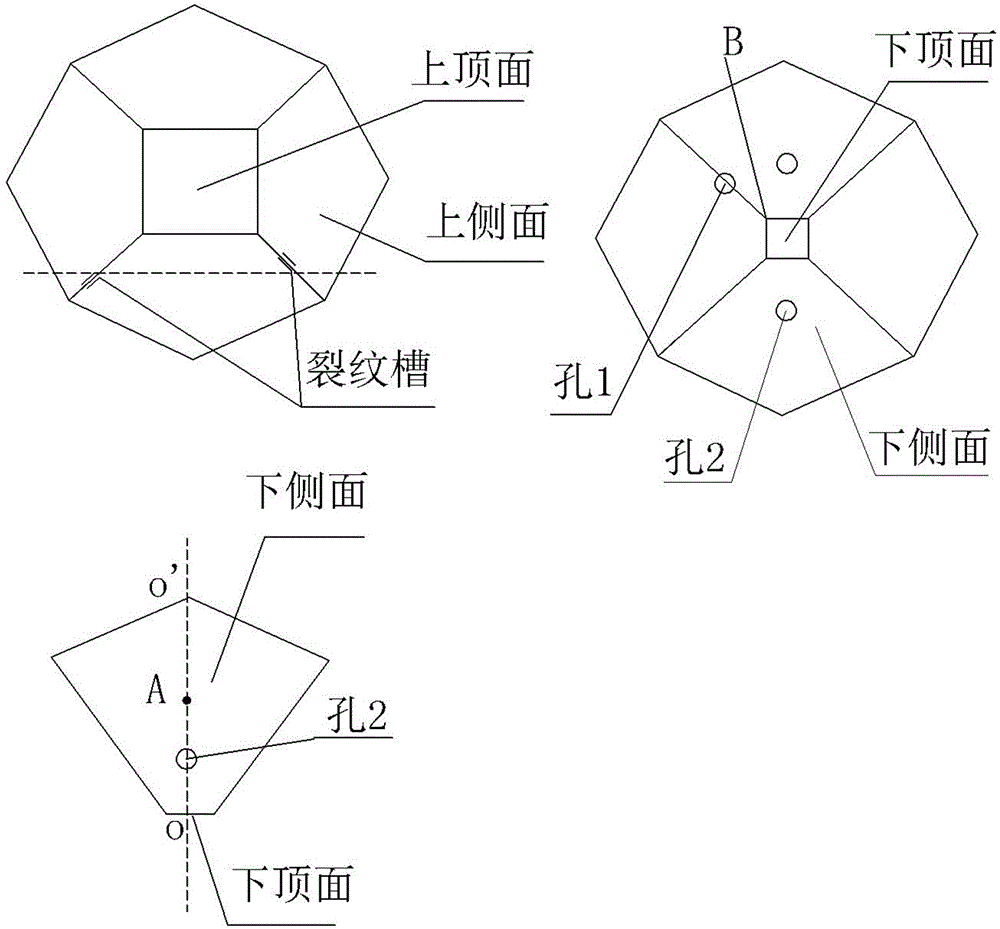

Detection method for inner defects of polyhedral hard alloy anvil cell

ActiveCN105021701AEasy to operateIntuitive test resultsAnalysing solids using sonic/ultrasonic/infrasonic wavesPhysicsEngineering

The invention relates to a detection method for inner defects of a polyhedral hard alloy anvil cell. Phased array ultrasonic inspection equipment is utilized; an upper top surface adopts longitudinal wave detection with a wedge block angle of 0 degree and a -30 degree-30 degree sector-shaped scanning manner is adopted; other eight side surfaces adopt transverse wave detection with a wedge block angle of 30-45 degrees; a sector-shaped scanning manner that a scanning starting angle is 30-40 degrees and a scanning stopping angle is 60-70 degrees is adopted; the detection starting sensitivity is determined by a sensitivity test block; the sensitivity test block is the polyhedral hard alloy anvil cell; a flat bottom hole is formed in the central line of a lower side surface, and the same hole is formed in the same position of a lower side surface corresponding to the lower side surface; a transverse hole is formed in a long edge, connected with the lower side surface, of one lower side surface; and crack grooves are formed in two edges, connected with the upper top surface, of one upper side surface respectively in a staggered manner. The method provided by the invention can be used for detecting the inner defects of the polyhedral hard alloy anvil cell, can detect the inner defects of the hard alloy with a minimum 0.1-mm equivalent weight hole and does not cause leaked detection.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Bar loading auxiliary equipment

ActiveCN105563215BReduce investmentReduce labor intensityAutomatic workpiece supply/removalMetal working apparatusNumerical controlMachine tool

Owner:XUZHOU SANHE MACHANICAL PARTS

A kind of solid beverage prepared with pollen soluble extract

ActiveCN103535835BHigh extraction rateImprove solubilityFood ingredient functionsFood preparationAdditive ingredientPollen

The invention provides a solid beverage prepared from soluble component extracts obtained from pollen, which comprises the following raw materials in percentage by weight: 5-30% of pollen soluble component extracts and 70-95% of auxiliary materials, wherein the pollen soluble component extracts contain 29.7-33.1% of proteins, 5.4-6.3% of fatty substances, 0.2-0.4% of polyphenol and 40.1-43.6% of total sugar. The prepared solid beverage contains abundant nutritional components and is high in effective component content.

Owner:北京世纪京纯蜂产品有限责任公司

Programmable Bluetooth intelligent servo motor

InactiveCN108712022AMeet learning needsEasy to expand functions externallyProgramme-controlled manipulatorAssociation with control/drive circuitsComputer moduleEngineering

The invention discloses a programmable Bluetooth intelligent servo motor. The servo motor is applied to an intelligent vehicle programmable robot. The servo motor comprises a motor body and a controlcircuit board. The control circuit board is connected with the motor body. A main control chip, a driving chip, a position detection circuit, a temperature detection circuit, a GSM module, a Bluetoothmodule, a port unit and a power supply unit are arranged on the control circuit board. One end of the power supply unit is connected with a power supply and the other end of the power supply unit isconnected with the power supply end of the main control chip. The port unit is arranged on the control circuit board and in communication connection with the main control chip. According to the invention, the servo motor is capable of timely responding and executing programming actions to drive the intelligent vehicle rotor to move; and through combination of cooperation of a materialized jigsaw type programmable plate and a programming instruction module, learning objectives of the programmable of children are finished and learning requirements of the children are met.

Owner:福建省乐探教育科技有限公司

Special clamp for transmission piston die-casting part of rack

InactiveCN102554644AEasy to operateUniversally applicablePositioning apparatusMetal-working holdersEngineeringBolt connection

The invention discloses a special clamp for a transmission piston die-casting part of a rack, which is characterized in that a main body of the special clamp is a clamp body, a butt-joint head matched with the shape of the transmission piston die-casting part of the rack is formed at one end of the clamp body, and the special clamp is provided with two pressing claws symmetrically arranged relative to the transmission piston die-casting part of the rack. The pressing claws are connected onto the butt-joint head through pins, one external supporting pin is in bolt connection in the butt-joint head through a symmetrical center of the two pressing claws in a penetrating mode, the external supporting pin is provided with a pin cap with taper, and the pin cap is contacted with claw tails of the two pressing claws. By means of the application of the technical scheme of the special clamp, the special clamp is simple in operation and has universal applicability to different dimensional changes of the piston die-casting part. By means of the application of the special clamp for the transmission piston die-casting part of the rack, the process difficulty is reduced, and the product quality of the workpiece processing and the processing efficiency are greatly improved. In addition, the special clamp for the transmission piston die-casting part of the rack meets needs of volume production of the piston die-casting parts.

Owner:SUZHOU INST OF INDAL TECH

Novel textile softener and preparation method thereof

The invention provides a novel textile softener and a preparation method thereof. The novel textile softener is prepared from the following raw materials in parts by mass: 20 parts of amino silicon oil, 4 to 6 parts of AEO-3 (carbon 12-13 fatty alcohol polyoxyethylene ether), 4 to 6 parts of TX-10 (alkylphenol ethoxylates), 0.3 to 0.6 part of glacial acetic acid and 70 parts of deionized water. The softener prepared by the method and the raw materials has the characteristics that the softener is suitable for large-scale production and the ammonia value content meets the use requirements.

Owner:扬州宏远新材料股份有限公司

Method and device for manufacturing LED lamp strip circuit board through single-face roller coating

PendingCN114466523AReduce copper foil consumptionReduce material consumption, energy consumption and pollutant generationConductive pattern formationConductive material chemical/electrolytical removalWater pipeInsulation layer

The invention discloses a method and device for manufacturing an LED lamp strip circuit board through single-face roller coating, and belongs to the technical field of LED lamp strip circuit boards. The method comprises the steps of base material combination, front circuit layer manufacturing, via hole manufacturing, via hole metallization and surface copper thickening manufacturing, product conduction performance detection, surface insulation layer manufacturing, character layer manufacturing, bonding pad surface treatment, appearance manufacturing, finished product inspection and detection and the like. The rotary drum is driven by a rotary table on one side to rotate, limiting plate assemblies are arranged on a supporting bottom plate of the rotary drum in an annular array mode to limit a circuit board workpiece, a drainage channel is formed in the center of the supporting bottom plate, a water collecting barrel is arranged below the drainage channel, and the drainage channel is connected with a bottom plate of the water collecting barrel through a bearing. A water pump is arranged in the water collecting cylinder and connected with a backflow pipe, a filtering assembly is arranged on the backflow pipe, the backflow pipe is communicated with a cleaning water pipe, and a water outlet pipe with a nozzle is connected to the cleaning water pipe.

Owner:湖南省方正达电子科技有限公司

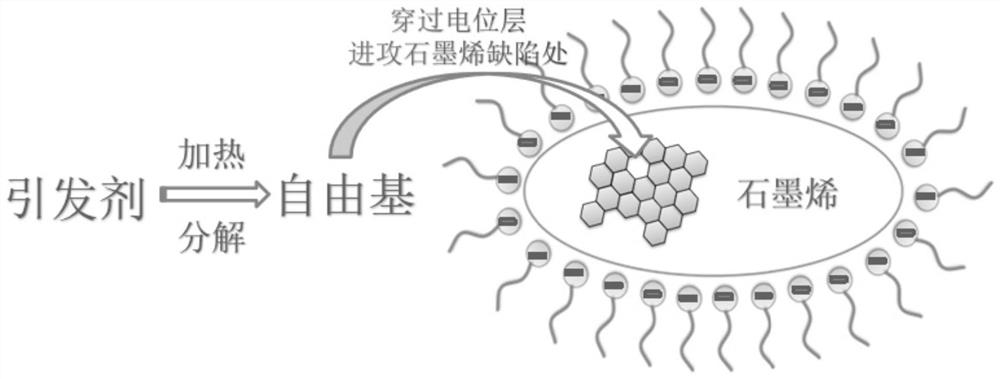

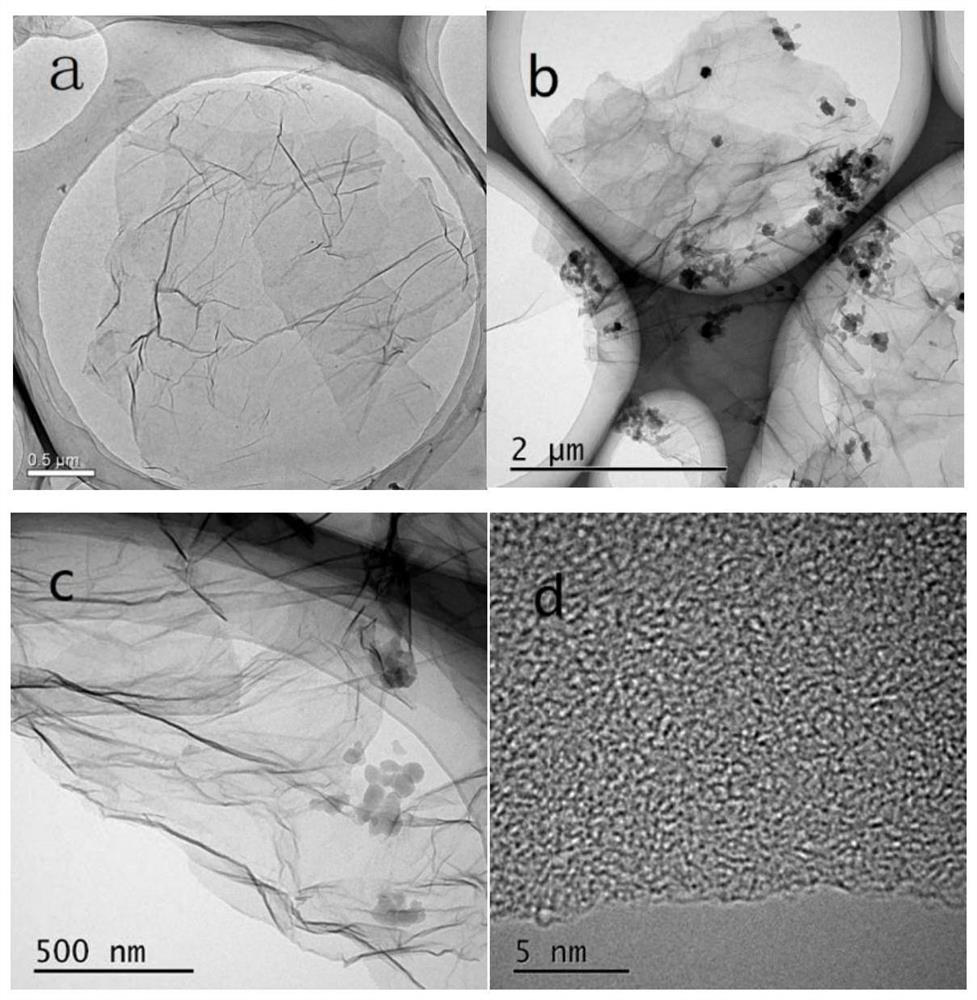

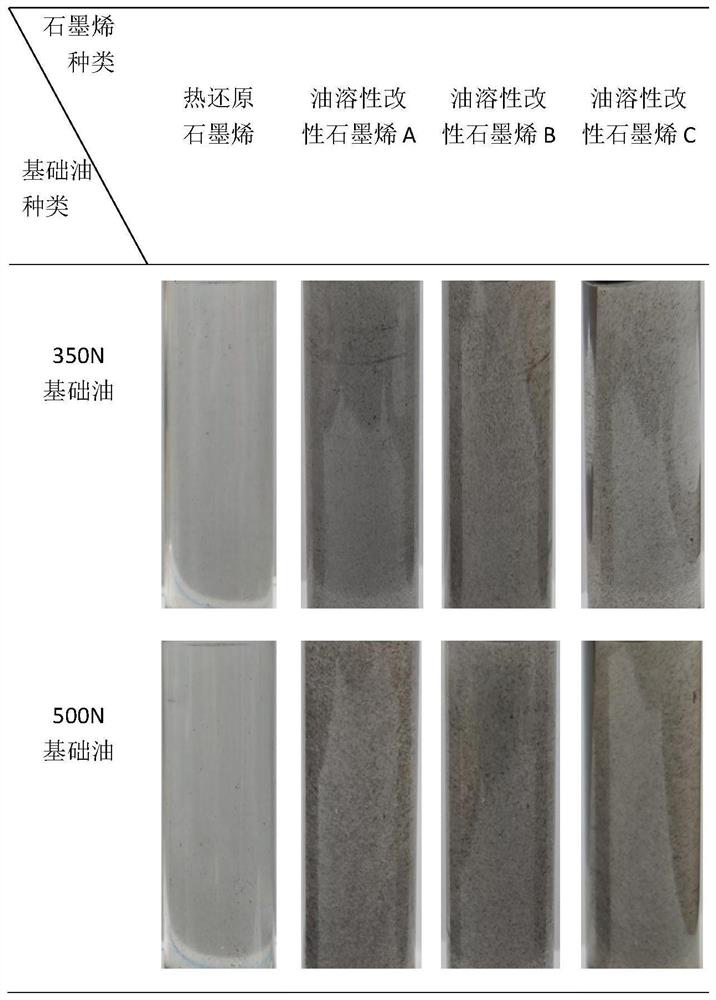

A kind of method for preparing oil-soluble modified graphene

The invention provides an oil-soluble modified graphene and a preparation method thereof, comprising the following components calculated in parts by weight: 1-5 parts of thermally reduced graphene, 2-10 parts of surfactant, 5-10 parts of initiator , 75‑92 parts deionized water. The oil-soluble modified graphene of the present invention is modified by organically modifying the central defects of thermally reduced graphene, forming emulsion micelles with graphene and surfactants in deionized water, and initiating at 60-80°C. The agent decomposes into free radicals and enters into the emulsion micelles, and then attacks the defects in the heat-reduced graphene to undergo an organic modification reaction. After the reaction, the emulsion is demulsified by absolute ethanol to obtain organically modified graphene. The present invention proposes The preparation process of the oil-soluble modified graphene is simple, the cost is low, and it is easy for large-scale industrial production.

Owner:重庆烯达科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com