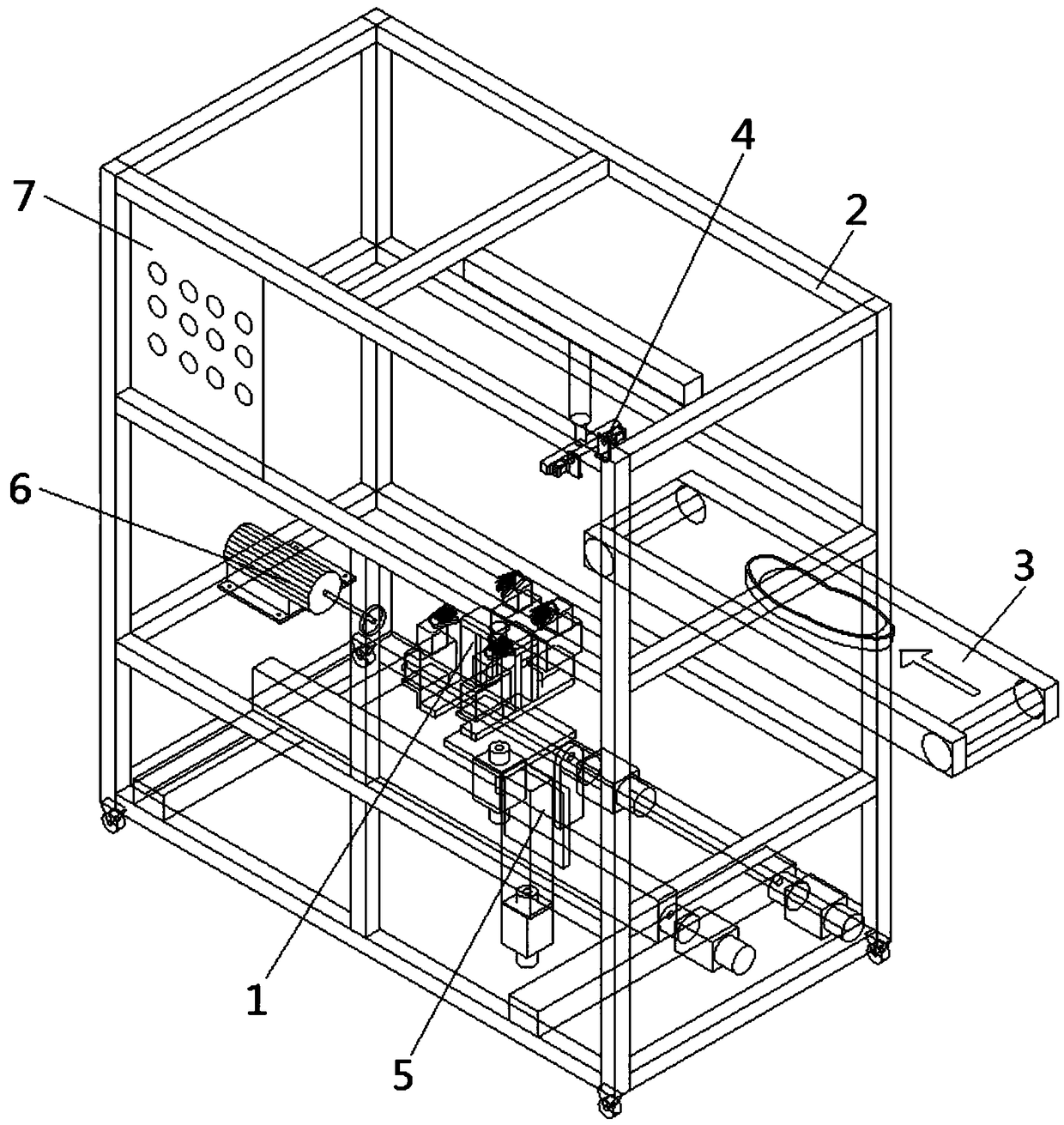

Shoe sole pressing profiling hand, shoe sole clamping device and full-automatic shoe sole grinding machine

A clamping device and a grinding machine technology, which is applied to shoemaking machinery, grinding machine parts, grinding/polishing safety devices, etc., can solve problems such as poor grinding effect, low efficiency, and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

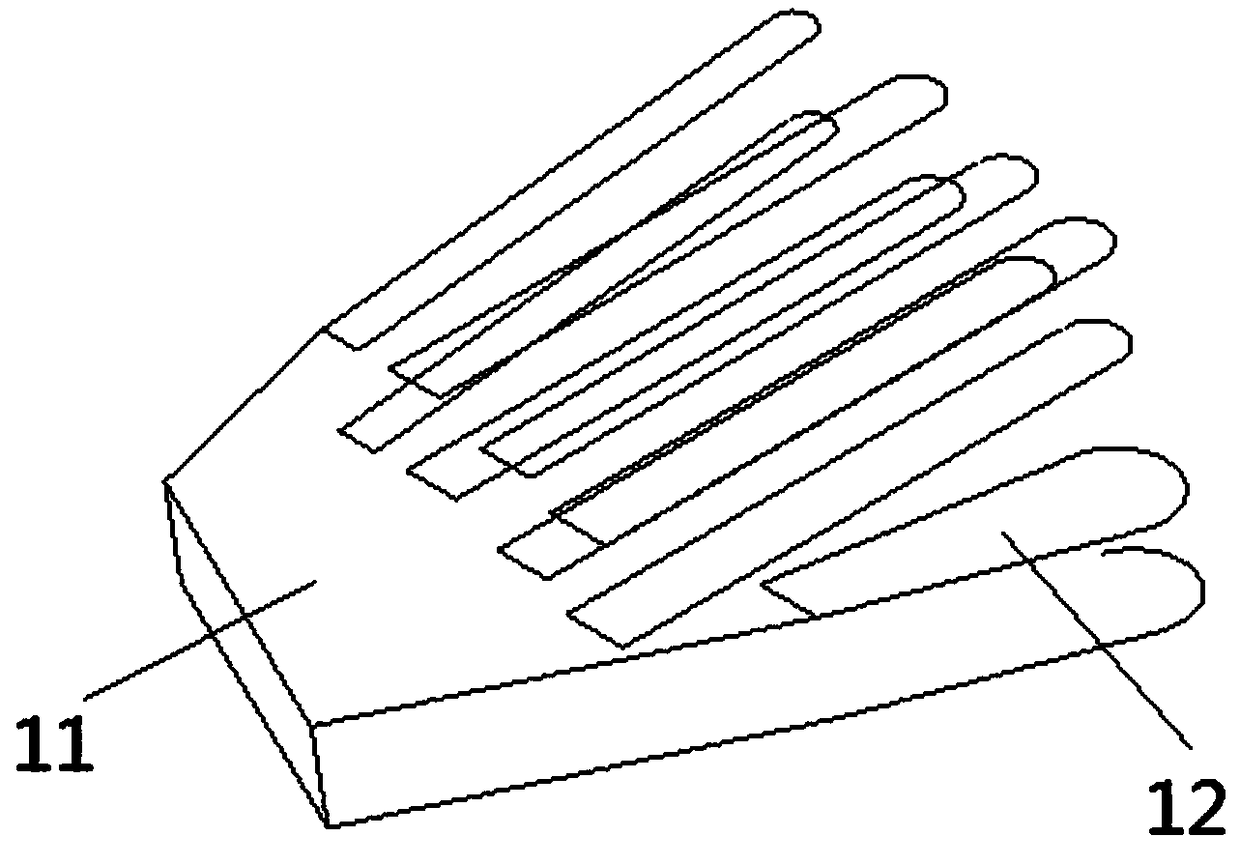

[0030] see figure 1 , The present invention relates to a shoe sole pressing profiling hand, comprising a base block 11 and several beading bars 12, the several beading bars 12 are arranged in sequence along one side of the base block 11, and the several beading bars 12 are not in the same plane.

[0031] In this embodiment, a total of five beading bars 12 are arranged on the base block 11 . The bead 12 on the base block 11 is not in the same plane. The bead 12 can adapt to the surfaces of different heights of the sole, and better fit the shape of the sole, so that the sole is pressed by the profiling hand to press the sole more firmly and reliably, stable and durable, and convenient for grinding.

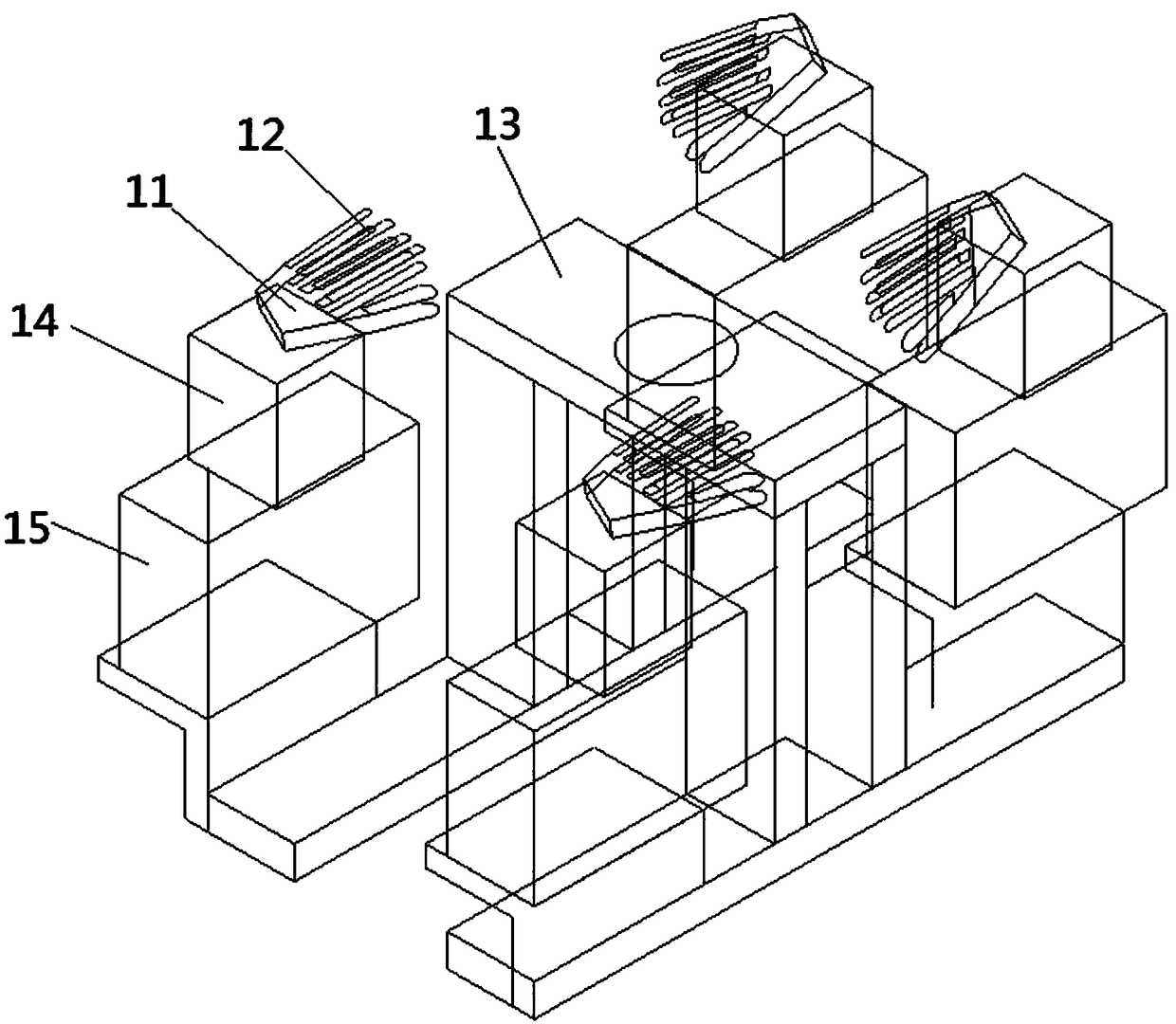

[0032] see figure 2 , the present invention also provides a shoe sole clamping device 1, comprising a bottom plate 13, a shoe sole pressing profiling hand, a motor 14, and a vertical drive module 15, the bottom plate 13 is arranged horizontally, and the sole pressing and profiling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com