Water-gas dual-sealing heat treatment atmosphere furnace

A water-sealed and double-sealed technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of low operation efficiency, high cost, matching and other problems, and achieve strong equipment scalability, improved production efficiency, and fast furnace installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

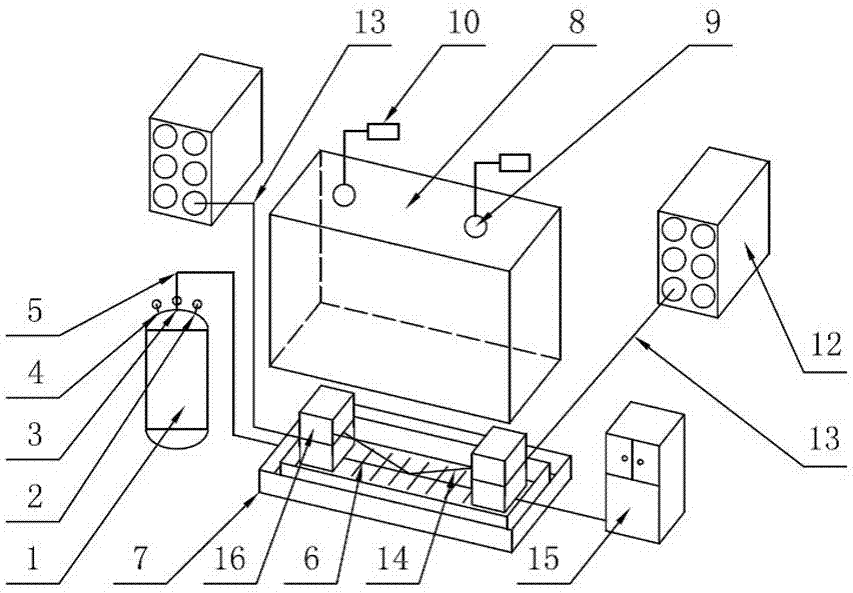

[0038] The heat treatment process steps of the water-air double-sealed heat treatment atmosphere furnace for 20G steel pipes are:

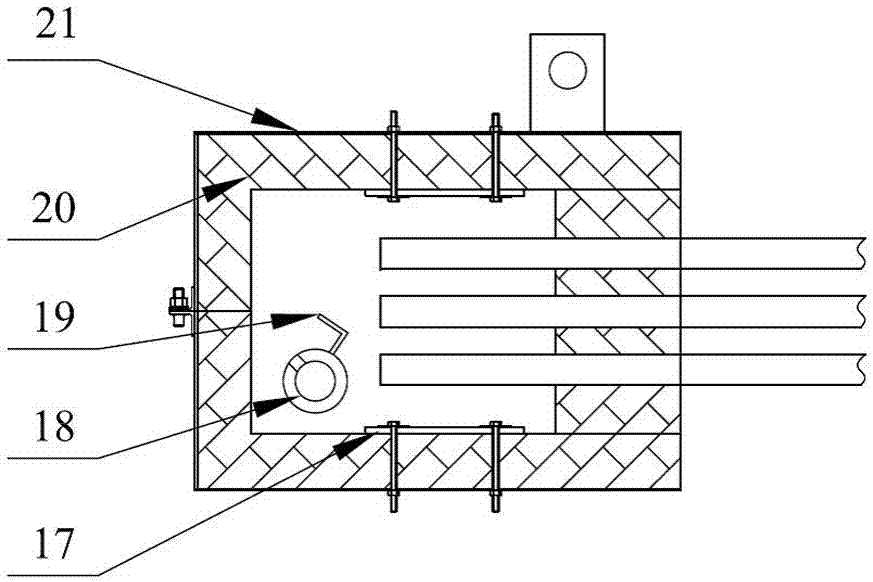

[0039] 1. Put 20G steel pipes into the electric heating furnace 15 one by one to ensure that the length and distance of the 20G steel pipes in the electric heating furnace 15 meet the heat treatment requirements, and place insulation cotton 20 between the layers of the workpiece.

[0040] 2. Bind and fix the thermocouple 14 on the 20G steel pipe, plug all the gaps tightly with insulation cotton 20, and close the 15 doors of the electric heating furnace.

[0041] 3. Water is poured into the sealing groove of the water-seal base 7, and then the end of the water-seal case 8 is placed in the seal groove, and the water-seal base 7 and the water-seal case 8 form a sealed space.

[0042]4. After the liquid protective gas in the liquid gas cylinder 1 is vaporized, it enters the sealed space formed by the water-sealed base 7 and the water-sealed casing 8 t...

Embodiment 2

[0048] The heat treatment process steps of the water-gas double-sealed heat treatment atmosphere furnace for 12Cr1MoVG steel pipe are:

[0049] 1. Put the 12Cr1MoVG steel pipes into the electric heating furnace 15 one by one to ensure that the length and distance of the 12Cr1MoVG steel pipes in the electric heating furnace 15 meet the heat treatment requirements, and place insulation cotton 20 between the layers of the workpiece.

[0050] 2. Bind and fix the thermocouple 14 on the 12Cr1MoVG steel pipe, plug all the gaps tightly with insulation cotton 20, and close the 15 doors of the electric heating furnace.

[0051] 3. Water is poured into the sealing groove of the water-seal base 7, and then the end of the water-seal case 8 is placed in the seal groove, and the water-seal base 7 and the water-seal case 8 form a sealed space.

[0052] 4. After the liquid protective gas in the liquid gas cylinder 1 is vaporized, it enters the sealed space formed by the water-sealed base 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com