Bar feeding assisting device

A kind of auxiliary equipment and bar technology, applied in the direction of metal processing equipment, metal processing machinery parts, metal processing, etc., can solve the problems of restricting the sustainable development of enterprises, not adapting to mass production, etc., to reduce labor consumption and capital. The effect of investment and equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

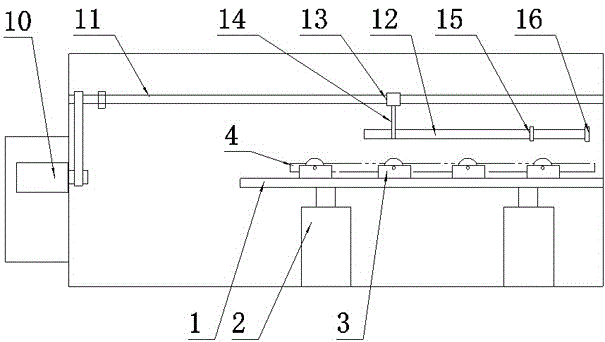

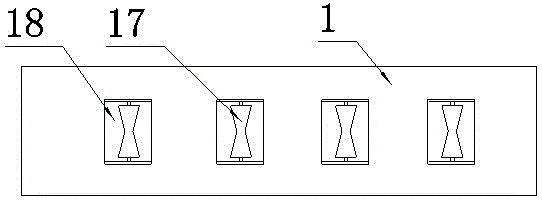

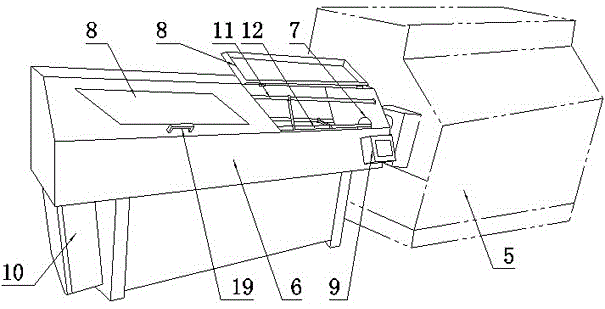

[0022] like Figure 1-4 The shown auxiliary equipment for feeding rods includes a lifting device and a pushing mechanism. The lifting device includes a workbench 1 and a lifting mechanism 2. The workbench 1 is provided with a support frame 3, and the rods to be processed 4 It can be erected on the support frame 3, and the lifting mechanism 2 drives the support frame 3 to move up and down, so that when the bar 4 rises to the top, it coincides with the center of the chuck of the CNC machine tool 5, so that the bar 4 can be placed in the CNC machine tool 5 for feeding on the bracket; the bar 4 can be moved toward the chuck through the push mechanism.

[0023] As a preferred structure, the lifting device and the pushing mechanism are arranged in the shield 6, and a through hole 7 for matching with the pushing mechanism is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com