Preparation method of sponge titanium test ingot

A sponge titanium and vacuuming technology is applied in the field of preparation of sponge titanium test ingots, which can solve the problems of unsuitable time duration, high energy consumption, low efficiency of sponge titanium test ingots, etc., and achieves high production efficiency, low energy consumption, time consumption short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

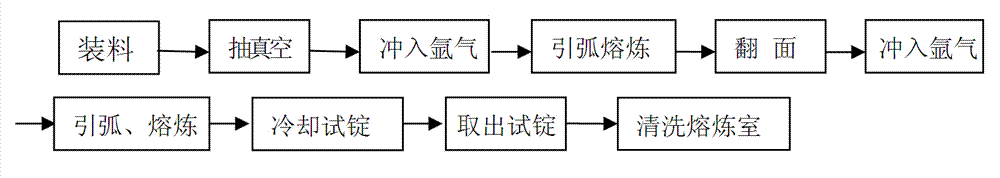

[0021] See figure 1 , a method for preparing a titanium sponge test ingot, the present invention will take the collected titanium sponge sample: sample loading→vacuumizing→smelting→turning over→smelting→cooling, sampling process line method processing, wherein:

[0022] 1) Loading: The collected sponge titanium samples are 0.4kg~0.6kg, stacked in a conical shape in the copper crucible of the button furnace; 1~6 samples can be placed at a time according to actual needs;

[0023] 2) Vacuuming: close the smelting chamber, and evacuate the pre-vacuum degree in the furnace to less than 1.0×10 -1 Torr=13.3Pa or less;

[0024] 3) Smelting: Input argon gas, start arcing and start smelting, and the current intensity during smelting is 100-400A;

[0025] 4) Turn over: After one-side smelting is completed, exhaust gas is removed, and the sample is turned over;

[0026] 5), melting; repeat the step 3;

[0027] 6) Cooling and sampling: After the smelting is over, wait for about 15 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com