Detection method for inner defects of polyhedral hard alloy anvil cell

A technology for cemented carbide and internal defects, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, and can solve problems such as the detection method for internal defects of unseen polyhedral cemented carbide anvils, and achieve intuitive detection results, simple operation and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

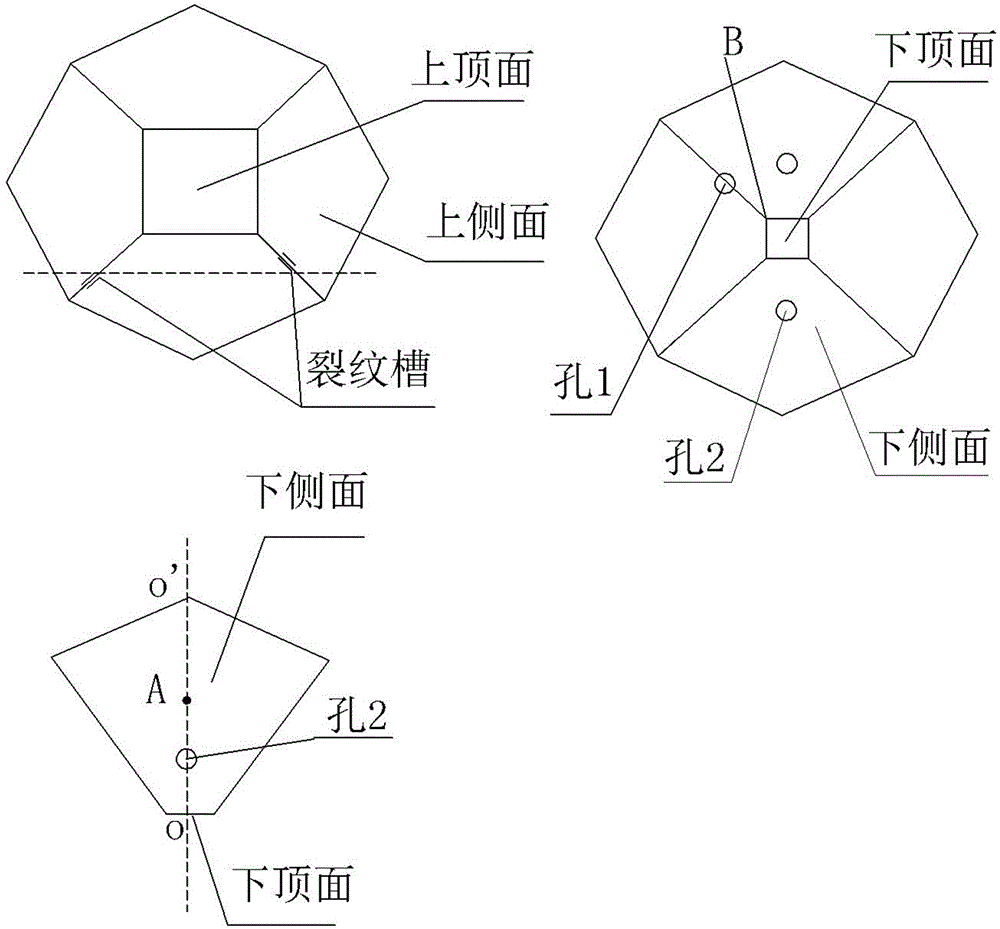

[0022] The method for detecting internal defects of a polyhedral cemented carbide anvil of the present invention is to use phased array ultrasonic testing equipment to perform ultrasonic testing on the nine faces of the polyhedral hard alloy anvil as ultrasonic testing surfaces, and the nine faces are respectively Upper top surface, four upper sides, four lower sides.

[0023] The top of the polyhedral cemented carbide anvil is used as the detection surface to mainly detect the internal macroscopic defects vertically downward; the upper side is the detection surface, which mainly detects the internal defects of the corresponding lower side and the surrounding area; the lower side is the detection surface, which mainly detects other defects. Corresponding internal defects on the upper side and its vicinity. The top and upper side are the working parts and the main stress-bearing parts. The corresponding ribs are prone to cracks during the production process, so strict requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com