Back edge flanging machine of automobile canopy

A technology of flanging machine and canopy, which is applied in the field of processing equipment for automotive interior parts, which can solve the problems of economic benefit impact, increased production cost of enterprises, and high scrap rate, so as to save energy consumption costs, improve product quality, and reduce labor costs. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

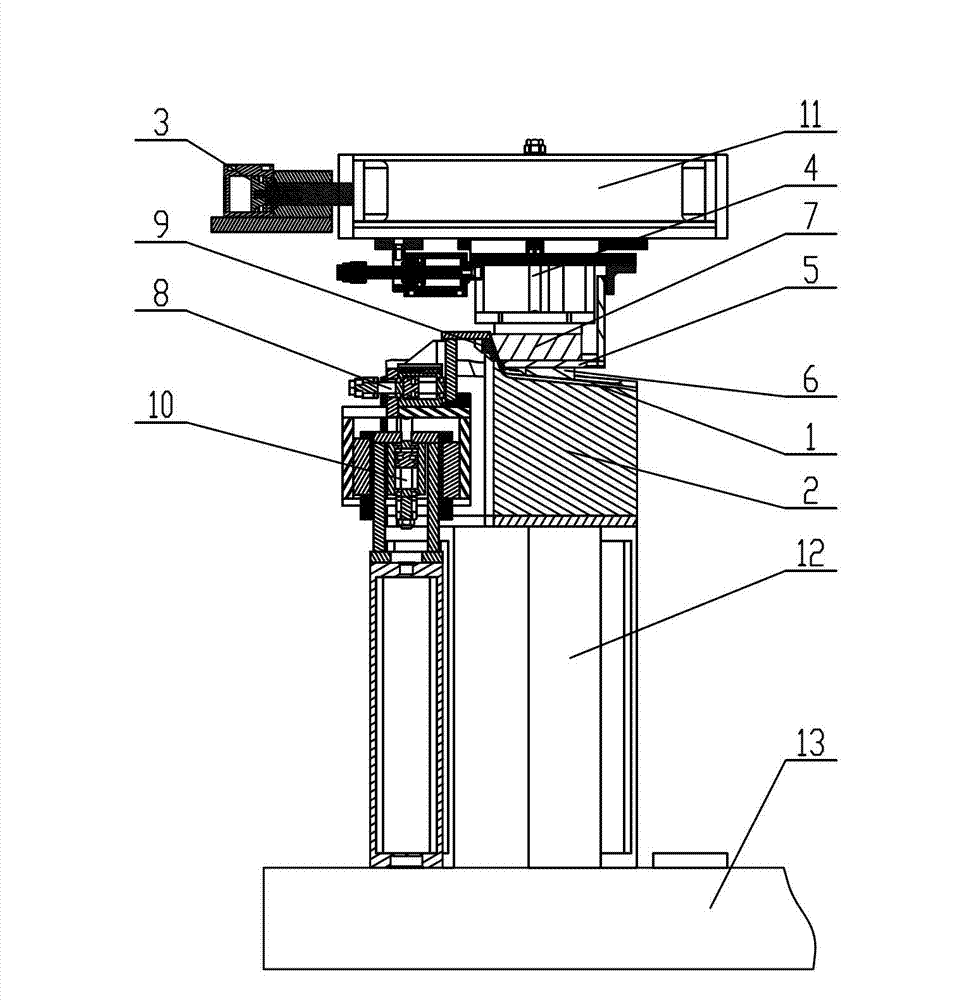

[0011] figure 1 Among them, it includes canopy 1, positioning mold 2, locking device 3, rear edge heating device 4, rear edge inserting device 5, elastic pressing plate 6, heating block group 7, horizontal moving cylinder 8, flange pressing die 9, Vertical cylinder 10, upper workbench 11, positioning mold base 12, lower workbench 13, etc.

[0012] Such as figure 1 As shown, the present invention is a rear edge flanging machine of a car roof, and an upper workbench 11 and a lower workbench 13 parallel to each other are arranged on the frame. Upper workbench 11 is positioned at the top of lower workbench 13, and upper workbench 11 can move up and down, and lower workbench 13 is fixed on the frame.

[0013] A locking device 3 is installed on the side of the upper workbench 11, which can lock the position of the upper workbench 11 to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com