Tungsten crucible internal defect detection method

A detection method and internal defect technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve problems such as tungsten crucible detection methods that have not been seen, achieve intuitive detection results, fast detection speed, and avoid missed detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings.

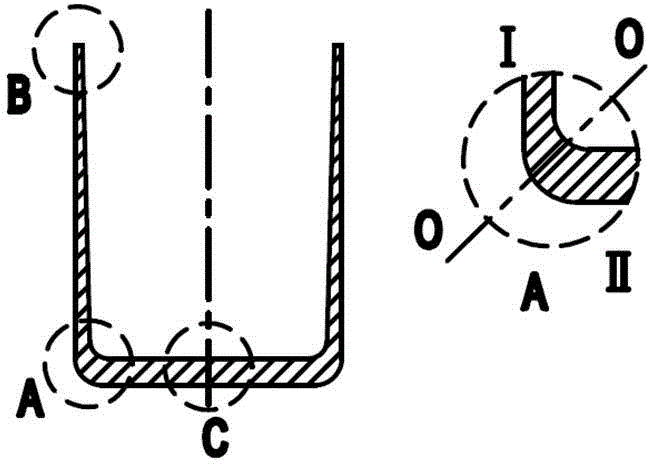

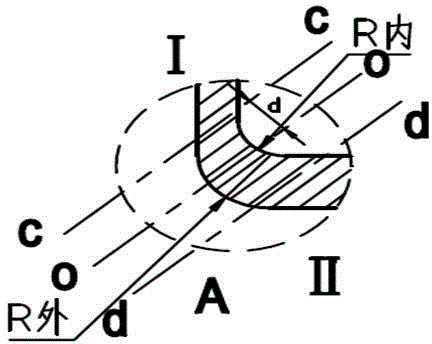

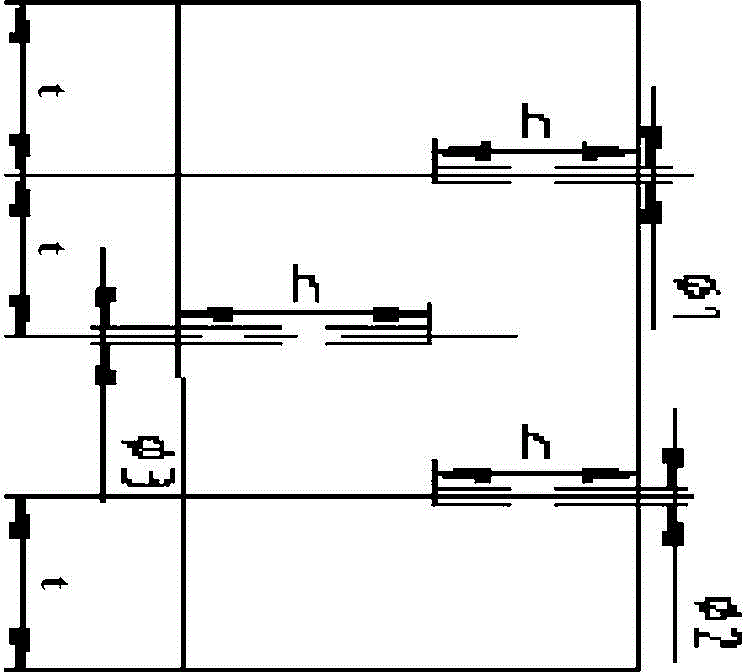

[0020] The first group of embodiments uses phased array ultrasonic testing equipment to divide the tungsten crucible into three parts for ultrasonic testing. figure 1 ), the double-crystal phase-controlled detection method is used for the tungsten crucible wall, and the phased-array ultrasonic detection is carried out with a dual-crystal probe; the phased-array ultrasonic detection is carried out with a phased Sensitivity test blocks used for detection of crucible wall and tungsten crucible bottom (see image 3 ) are tungsten plates whose length, width and height are 60-100mm, 30-50mm, and 30-50mm respectively. Three flat-bottomed holes with different diameters and the same depth are drilled inside by electric spark drilling, and the interval between the holes is greater than 5mm. , the pore diameters are 0.2-0.45 mm, 0.5-0.7 mm, 0.8-1.0 mm, and the pore depths of diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner radius | aaaaa | aaaaa |

| Outer radius | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com