Optical module adjustment test method and device

A test method and technology of optical modules, which are applied in the testing of optical instruments, measuring devices, and testing of machinery/structural components, etc., can solve problems such as soaring costs, low product yield, and difficulty in eliminating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

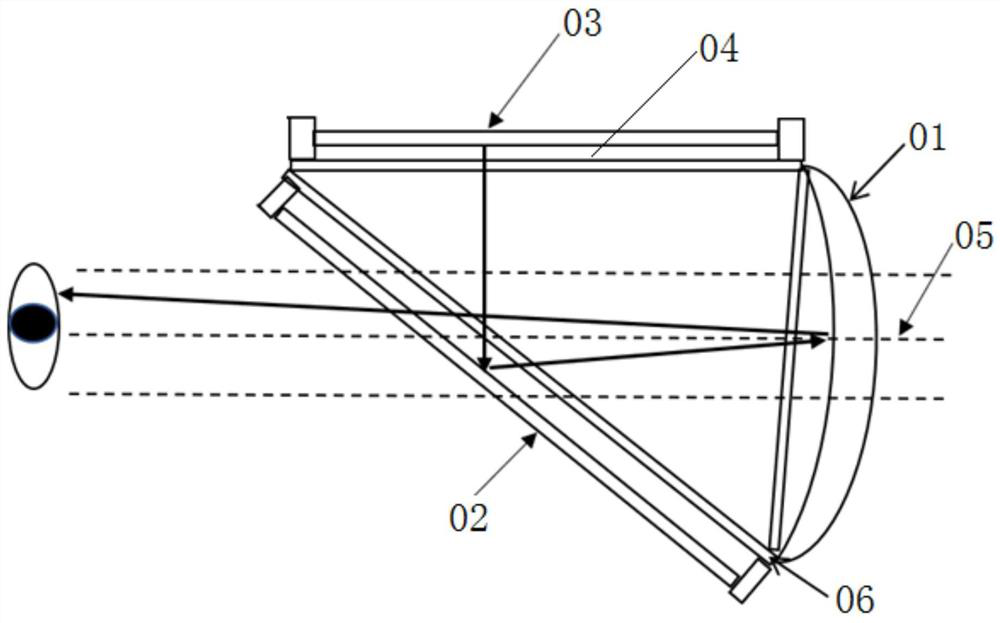

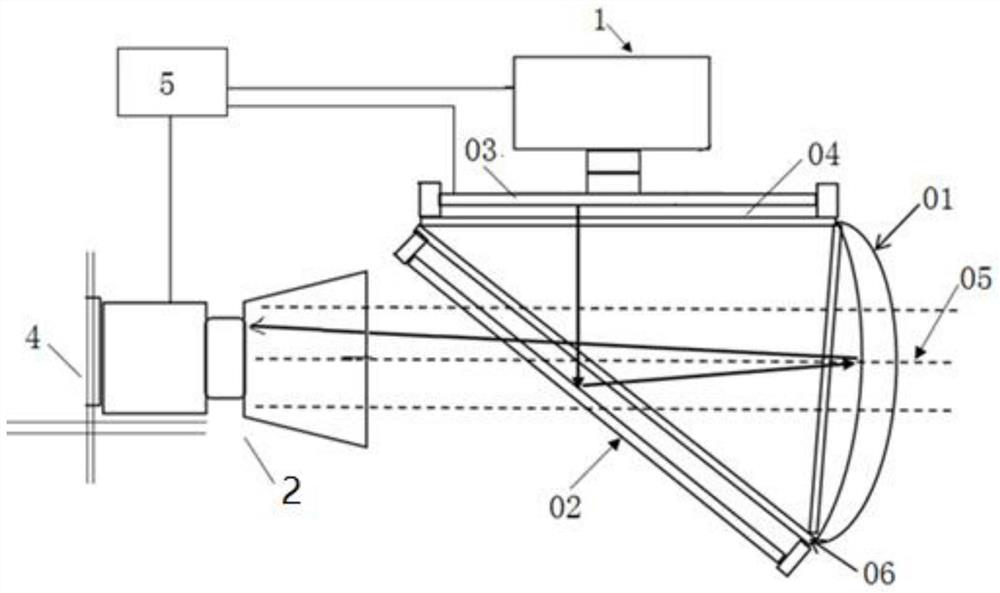

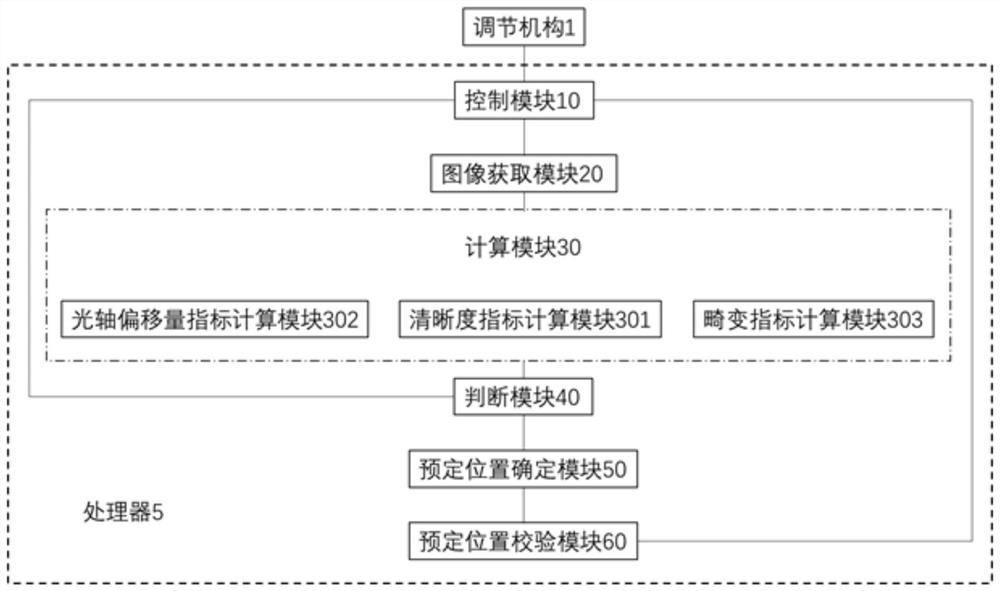

[0101] Aiming at the problem that the existing assembly and testing based on mechanical alignment cannot overcome the influence of aberration factors on the final imaging effect, the present invention provides a method and device for adjusting and testing optical modules. The display device is installed at a predetermined position relative to the main body of the optical module. The display device receives and displays the signal of the test legend, which is imaged in the human eye through the optical path transmission of the optical module. The installation accuracy of the display device affects the human eye. Imaging quality, the device sets a camera on the imaging optical path of the optical module to simulate the visual effect of the human eye, collects the imaging of the test pattern displayed by the display device in the camera, and judges the display through the image quality index of the collected test pattern Whether the installation position of the device is the prede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com