Special clamp for transmission piston die-casting part of rack

A rack drive and special fixture technology, which is applied in the field of special fixtures for industrial processing and special fixtures for turning operations, to achieve the effects of simple operation, reduced process difficulty, and improved product quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

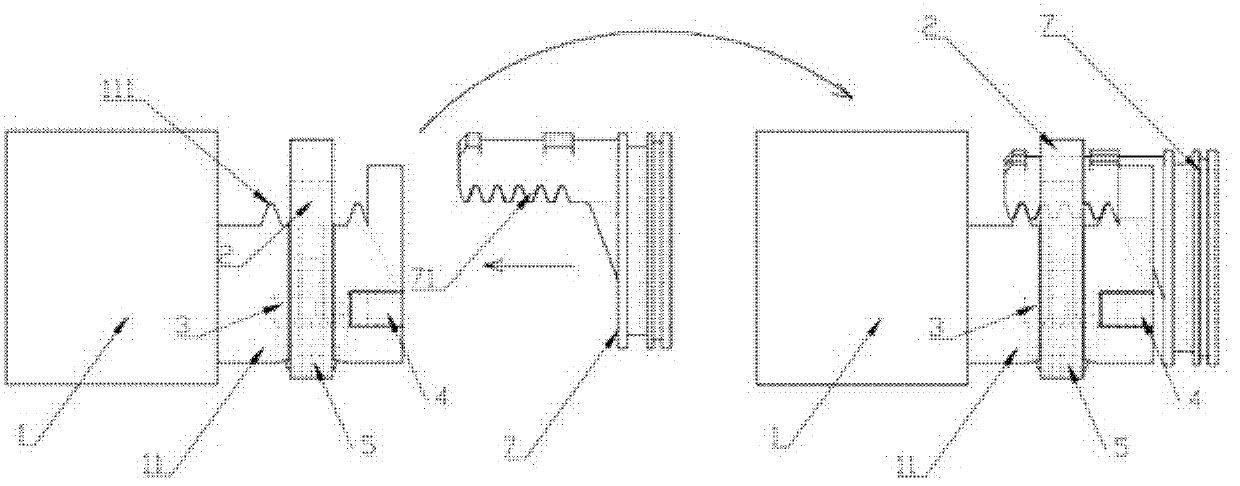

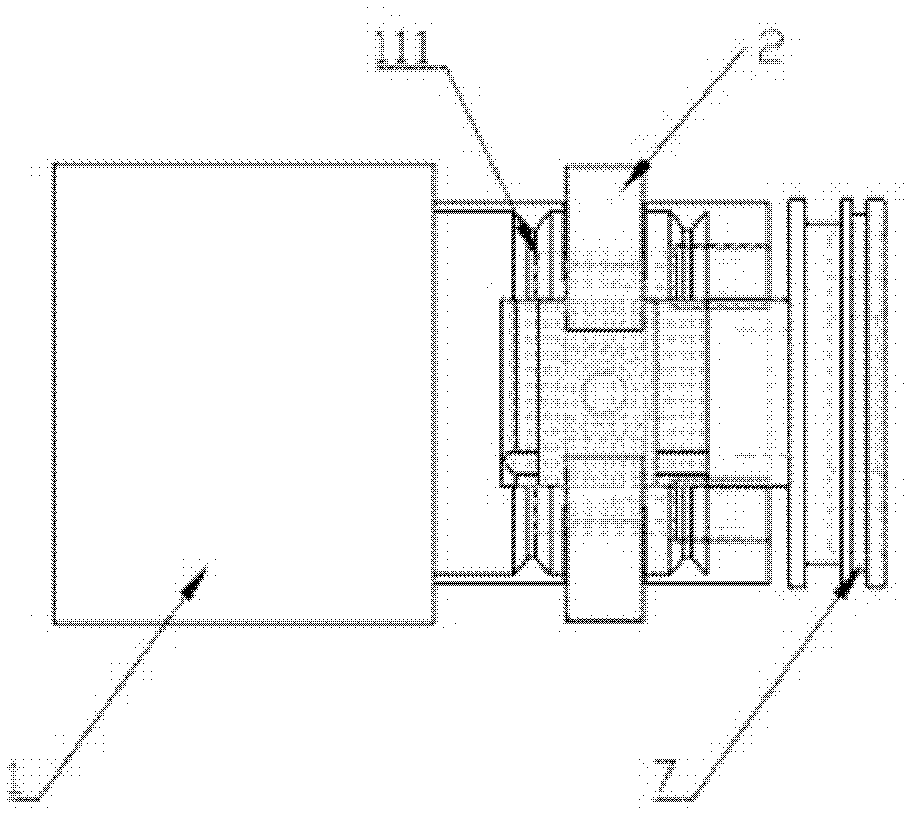

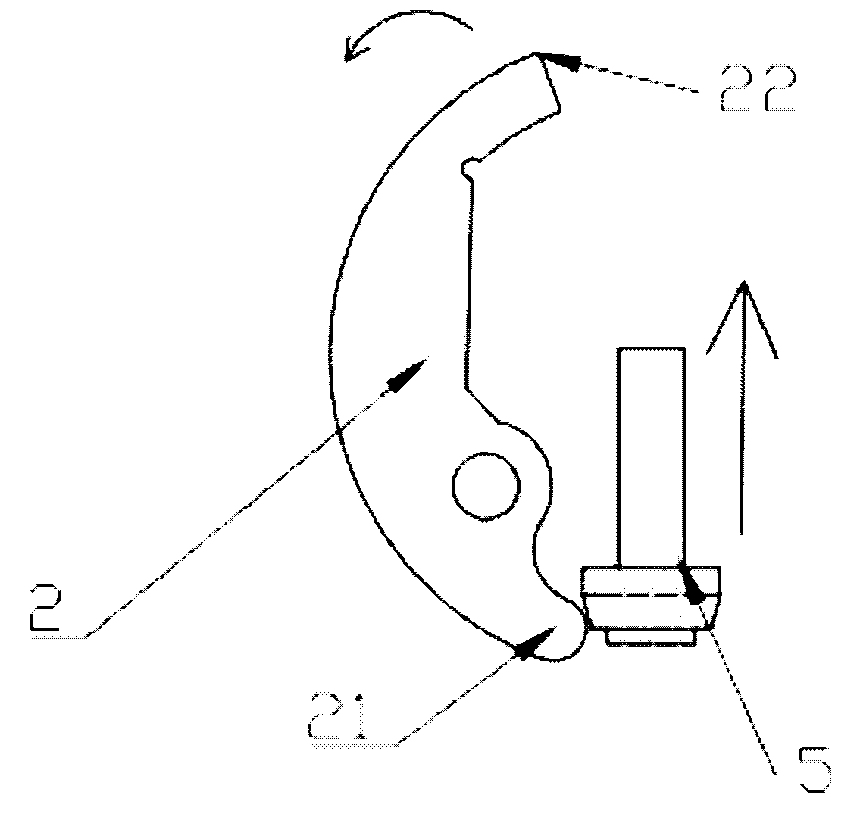

[0015] The present invention aims at the shortcomings of the existing lathe fixtures that require two clampings and step-by-step processing when clamping the die-casting parts of the rack transmission piston, and provides a new type of special fixture, through which, only one step can be processed The workpiece is securely clamped in place and subjected to the required high-intensity machining. Such as figure 1 As shown, the main body of the special fixture is a clamp body 1, and one end of the clamp body 1 forms a butt joint 11 that matches the shape of the die-casting part 7 of the rack transmission piston, and the special fixture has a shape that is symmetrical to the die-casting part 7 of the rack transmission piston. Two pressure claws 2 are provided, the pressure claws are connected to the butt joint 11 through the shaft pin 3, and an outer support pin 5 is threaded through the butt joint 11 from the symmetrical center of the two pressure jaws 2. The pin 5 has a tapered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com