Automobile roof skylight flanging machine

A technology of automobile sunroof and flanging machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

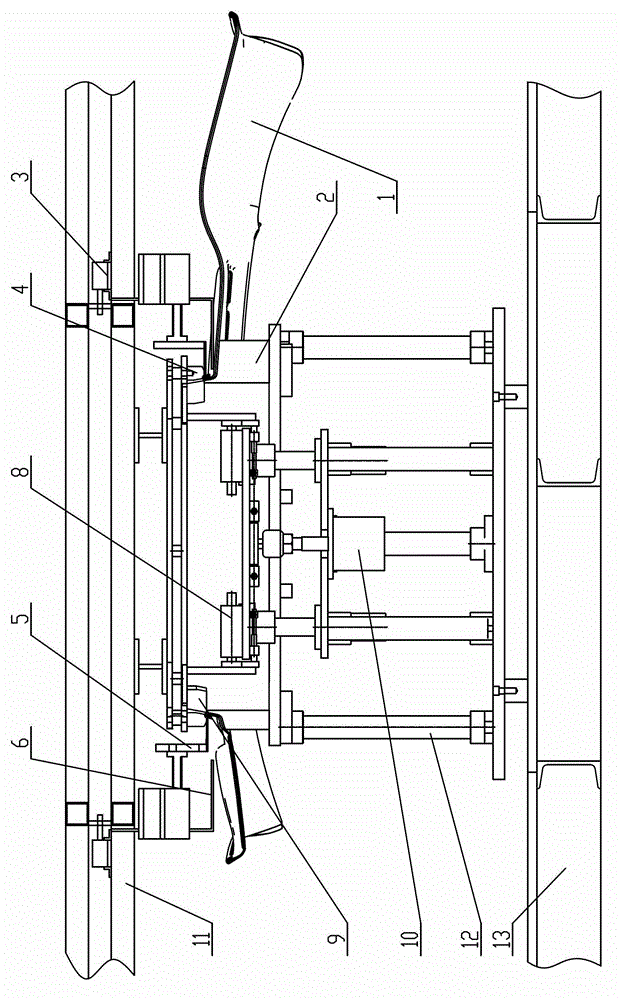

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] figure 1 Among them, including canopy 1, positioning mold 2, locking device 3, skylight heating mold 4, skylight insert piece 5, elastic pressure plate 6, horizontal moving cylinder 8, flange pressing mold 9, vertical cylinder 10, upper workbench 11 , Positioning mold base 12, lower workbench 13, etc.

[0012] Such as figure 1 As shown, the present invention is a car roof sunroof flanging machine, and an upper workbench 11 and a lower workbench 13 parallel to each other are arranged on the frame. Upper workbench 11 is positioned at the top of lower workbench 13, and upper workbench 11 can move up and down, and lower workbench 13 is fixed on the frame.

[0013] A locking device 3 is installed on the side of the upper workbench 11, which can lock the position of the upper workbench 11 to prevent misoperation. Locking device 3 adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com