A kind of method for preparing oil-soluble modified graphene

A graphene, oil-soluble technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as poor dispersion stability of graphene, and meet the needs of large-scale production, the process is simple, and the raw materials are easily available. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

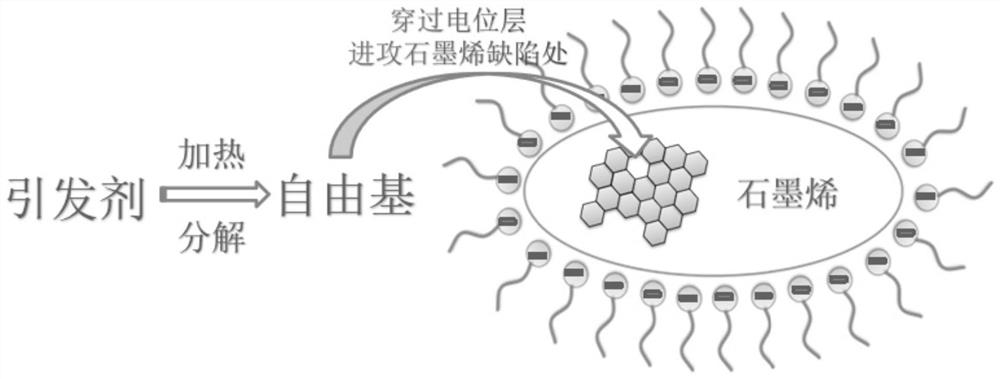

Method used

Image

Examples

Embodiment 1

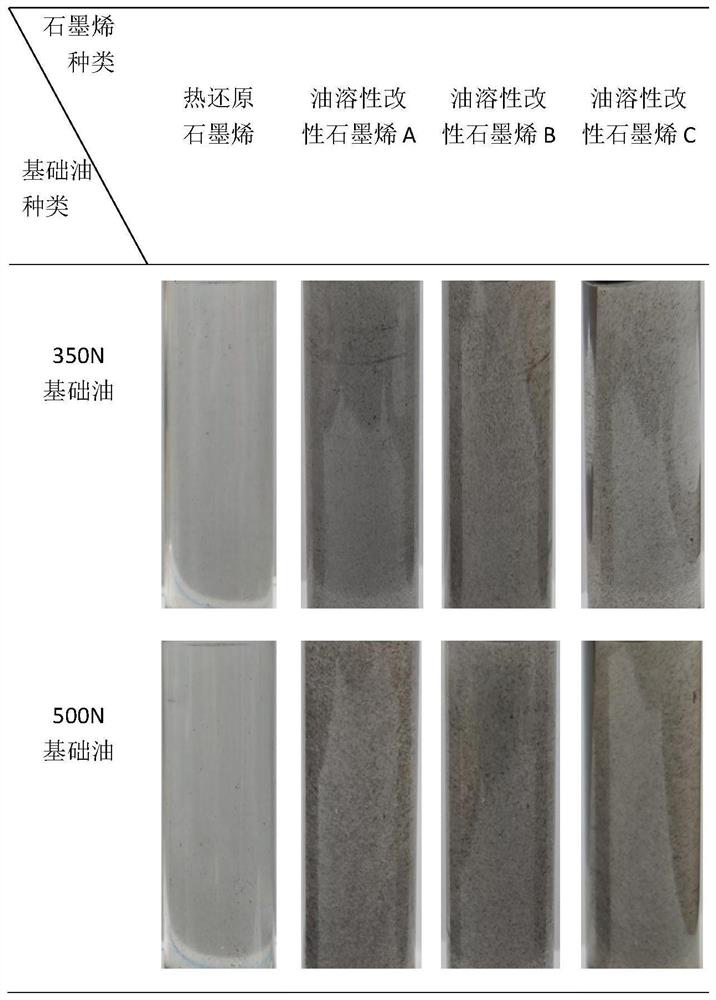

[0031] Add 91 parts of deionized water to the beaker, weigh 1 part of thermally reduced graphene, 3 parts of sodium lauryl sulfate, add to the beaker, stir for 1 hour, and obtain emulsion A; add 5 parts of diphenyl peroxide to emulsion A Formyl, stirred at 60°C for 10 hours; filtered the reacted solution and washed with absolute ethanol until the filtrate was clear. The filter cake was taken out, dried, collected, and ground into powder to obtain oil-soluble modified graphene A.

Embodiment 2

[0033] Add 90 parts of deionized water to the beaker, weigh 2 parts of thermally reduced graphene, 3 parts of cetyltrimethylammonium bromide, add to the beaker, stir for 1 hour, and obtain emulsion B; add 5 parts of Dibenzoyl peroxide was stirred at 70°C for 11 hours; the reacted solution was filtered and washed with absolute ethanol until the filtrate was clear. The filter cake is taken out, dried, collected, and ground into powder to obtain oil-soluble modified graphene B.

Embodiment 3

[0035] Add 87 parts of deionized water to the beaker, weigh 5 parts of thermally reduced graphene, 3 parts of sodium lauryl sulfate, add to the beaker, stir for 1 hour, and obtain emulsion C; add 5 parts of dibenzoyl peroxide to emulsion C , and stirred at 65° C. for 10 hours; the reacted solution was filtered and washed with absolute ethanol until the filtrate was clear. The filter cake was taken out, dried, collected, and ground into powder to obtain oil-soluble modified graphene C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com