Device for grinding groove of aluminum alloy profile

A technology of aluminum alloy profiles and notches, which is applied in the direction of grinding drive devices, grinding machines, grinding racks, etc., and can solve the problems of low efficiency of aluminum alloy profile grooves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

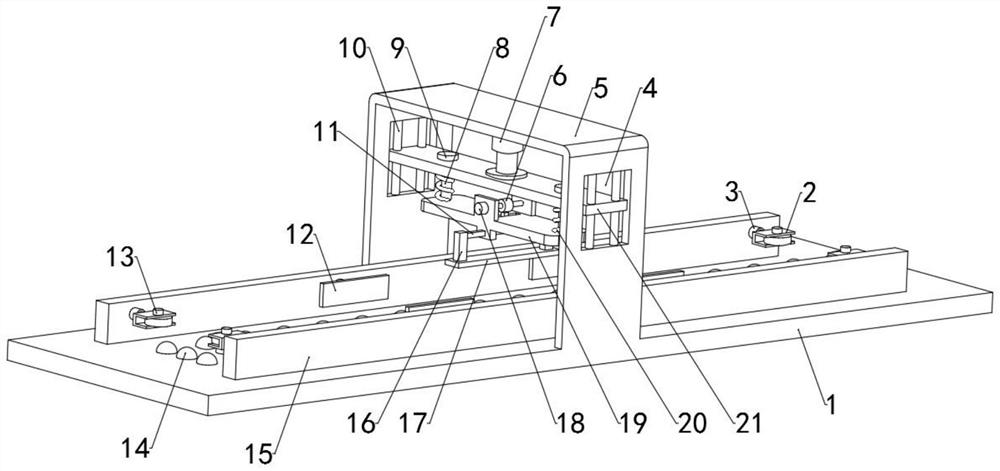

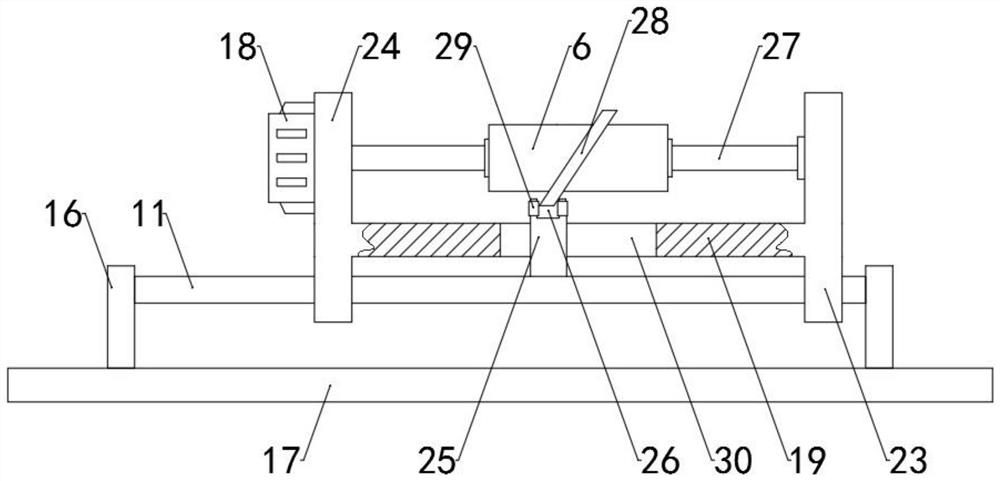

[0028] see Figure 1-3 , an aluminum alloy profile groove grinding device, including an operation panel 1, an inverted U-shaped support 5 is fixed on the top of the operation panel 1, and the inner cavity of the support 5 is provided with a hydraulic rod 7, a moving plate 21 and a buffer plate from top to bottom 19. One end of the hydraulic rod 7 is fixedly connected to the bracket 5, and the other end is fixedly connected to the moving plate 21. The moving plate 21 runs through a column 8, and the column 8 is slidably matched with the moving plate 21. A flange 9 is formed on the top of the column 8. The flange 9 prevents the column 8 from being separated from the moving plate 21, and the bottom end is fixedly connected to the upper surface wall of the buffer plate 19. A spring 20 is arranged between the moving plate 21 and the buffer plate 19, and the spring 20 is sleeved on the outside of the column 8. The spring When 20 is in the squeezed state, give the buffer plate 19 a v...

Embodiment 2

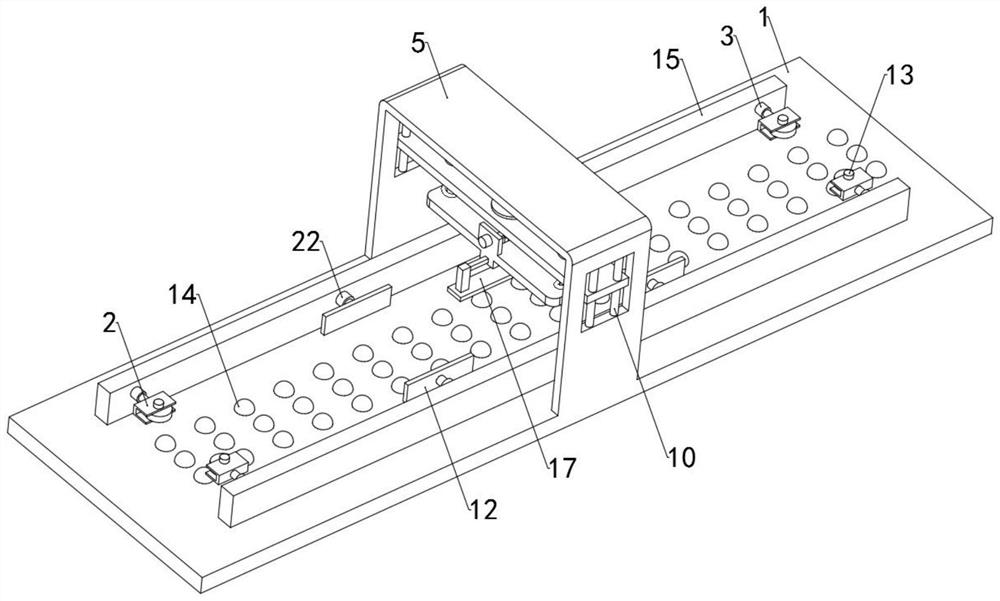

[0031] see figure 2 , The upper surface wall of the operation panel 1 is equipped with balls 14, the balls 14 avoid the friction between the aluminum alloy profiles and the operation panel 1, so that the movement of the aluminum alloy profiles is smoother.

[0032] The difference from Example 1 is that

Embodiment 3

[0034] see figure 1 , the outer walls of both sides of the bracket 5 are provided with a cavity 4, the inside of the cavity 4 is provided with a guide rod 10 that runs through the moving plate 21, the guide rod 10 is fixedly connected with the inner wall of the cavity 4, and the guide rod 10 is connected with the moving plate 21 Sliding fit, the guide rod 10 can limit the moving plate 21 so that the moving plate 21 can only move in the vertical direction.

[0035] The difference from Example 1 is that

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com