Hydrogenation reactor inlet diffuser

A hydrogenation reactor and diffuser technology, applied in the field of diffusers, can solve the problems of small liquid phase distribution area, easy occurrence of biased wall flow, uneven liquid phase distribution along the radial direction, etc., to achieve automatic adjustment and reduce impact , The effect of large operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

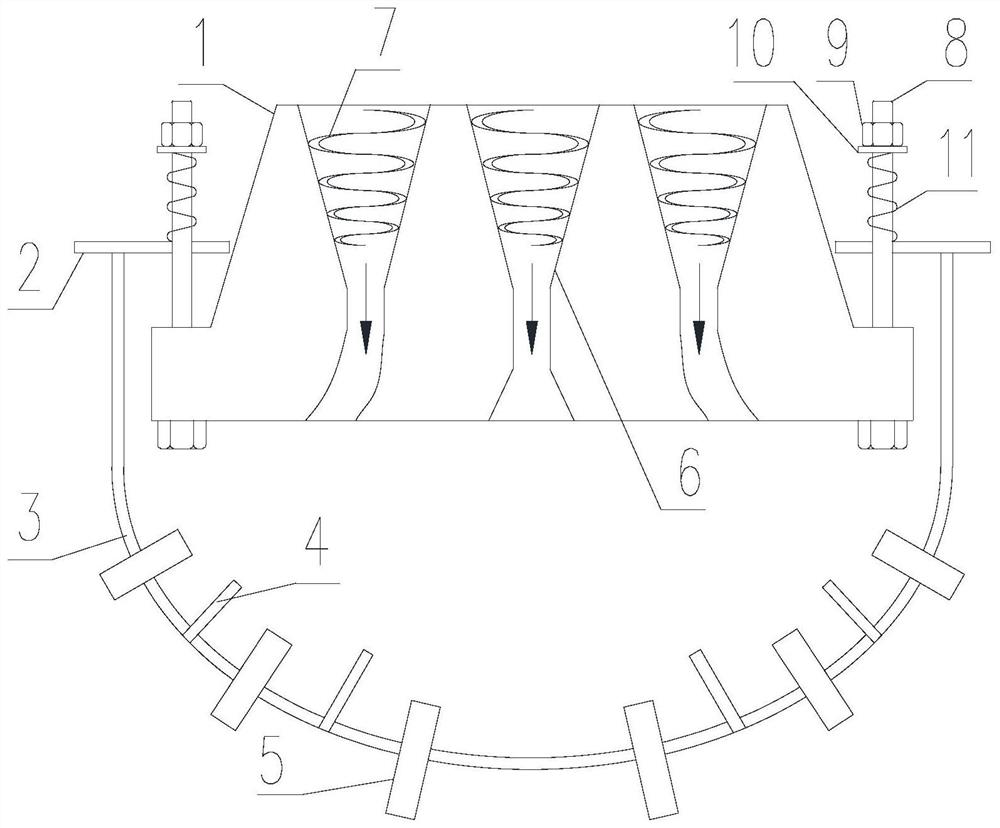

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

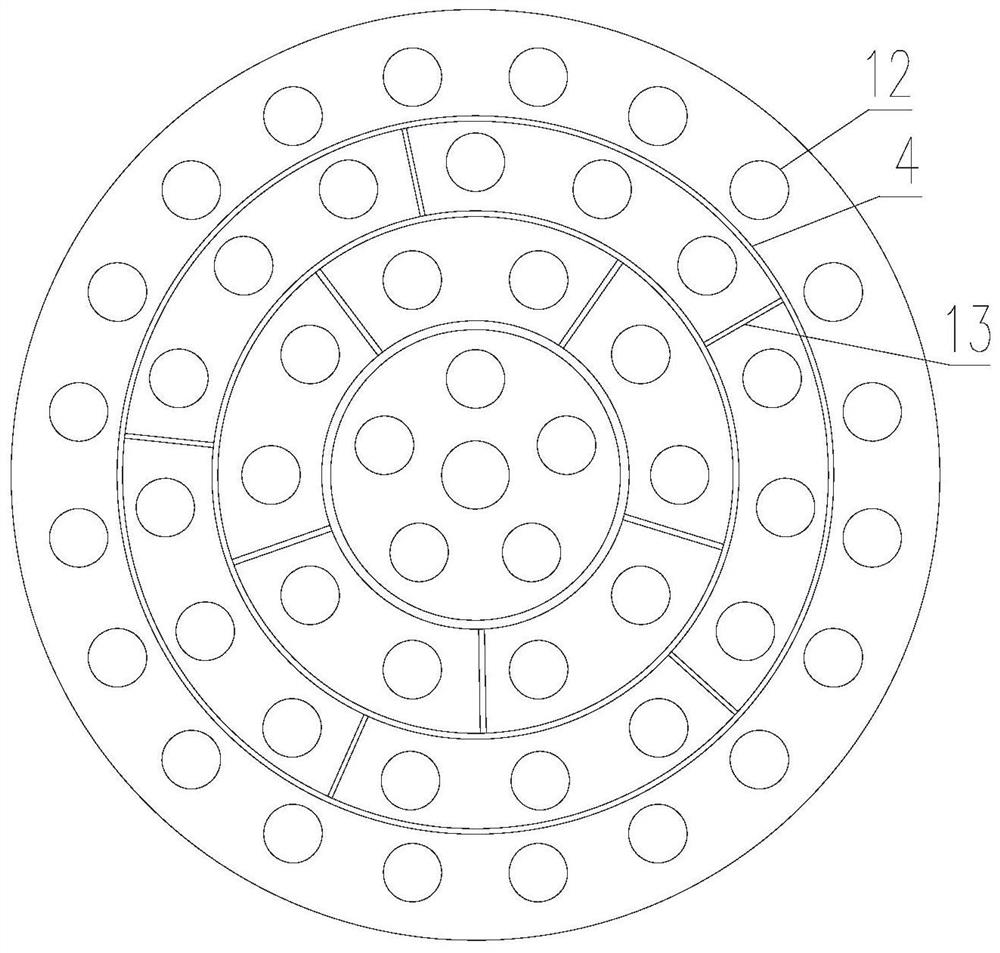

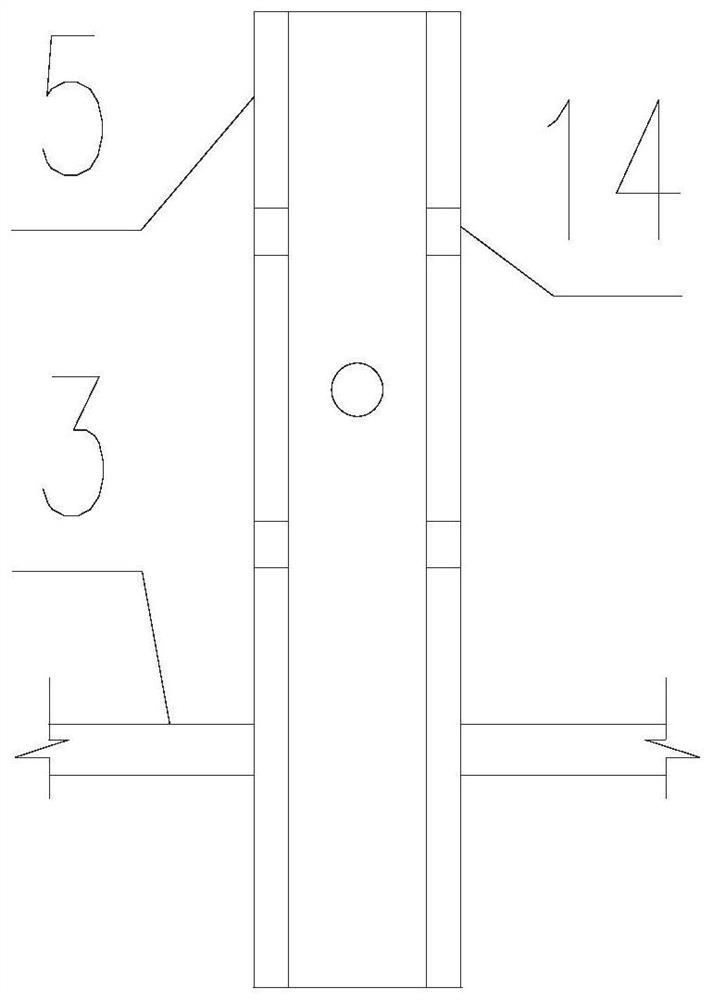

[0033] like figure 1 As shown, the inlet diffuser of the hydrogenation reactor of the present invention mainly includes an inlet cone 1, a mounting plate 2 and a spray cover 3; There is an upwardly erected guide column 8 on the edge. The upper surface of the inlet cone 1 is evenly distributed with swirl tubes 6. The upper part of the swirl tube 6 is an inverted conical closing structure, and the lower part is a guide tube that plays a guiding role. The outlet of the guide tube is fixed at On the lower surface of the inlet conical body, there is a rotating guide vane 7 in the inverted conical closing structure; the mounting plate 2 is a circular ring plate, which is provided with a cylindrical hole matching the guide column 8, and the mounting plate 2 is surrounded by its inner ring. On the outside of the inlet cone 1 and make the guide post 8 pass through its cylindri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com