Air cylinder cover casting technology adopted under limited sand box size condition

A casting process and cylinder head technology, applied in the field of cylinder head casting process, can solve the problem of large cylinder head size, achieve the effect of optimizing the gating system and overcoming the limitation of the size of the sand box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

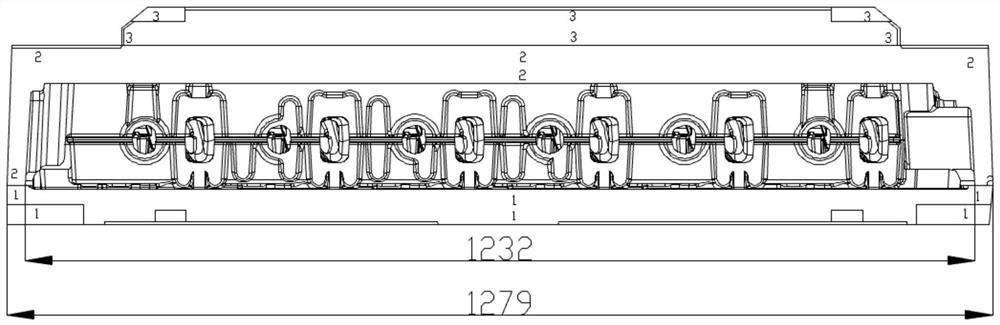

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

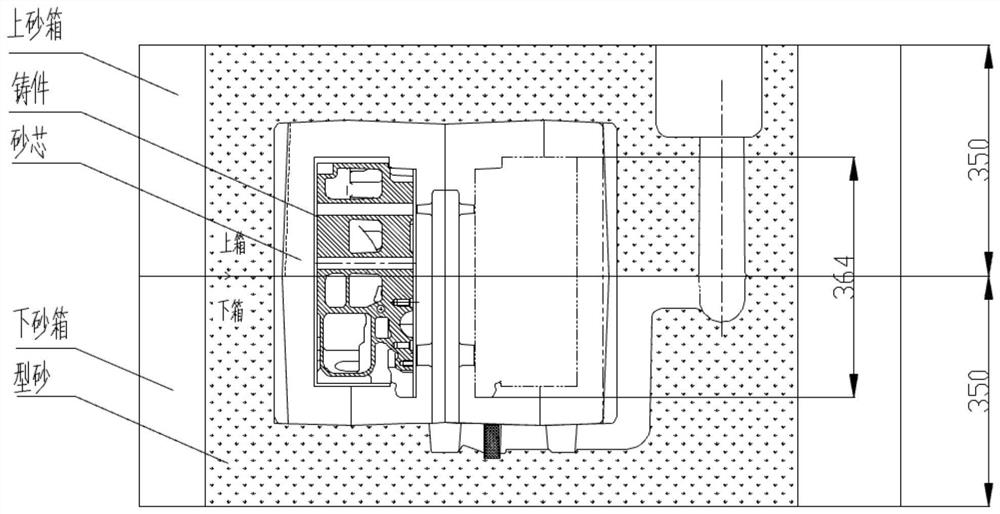

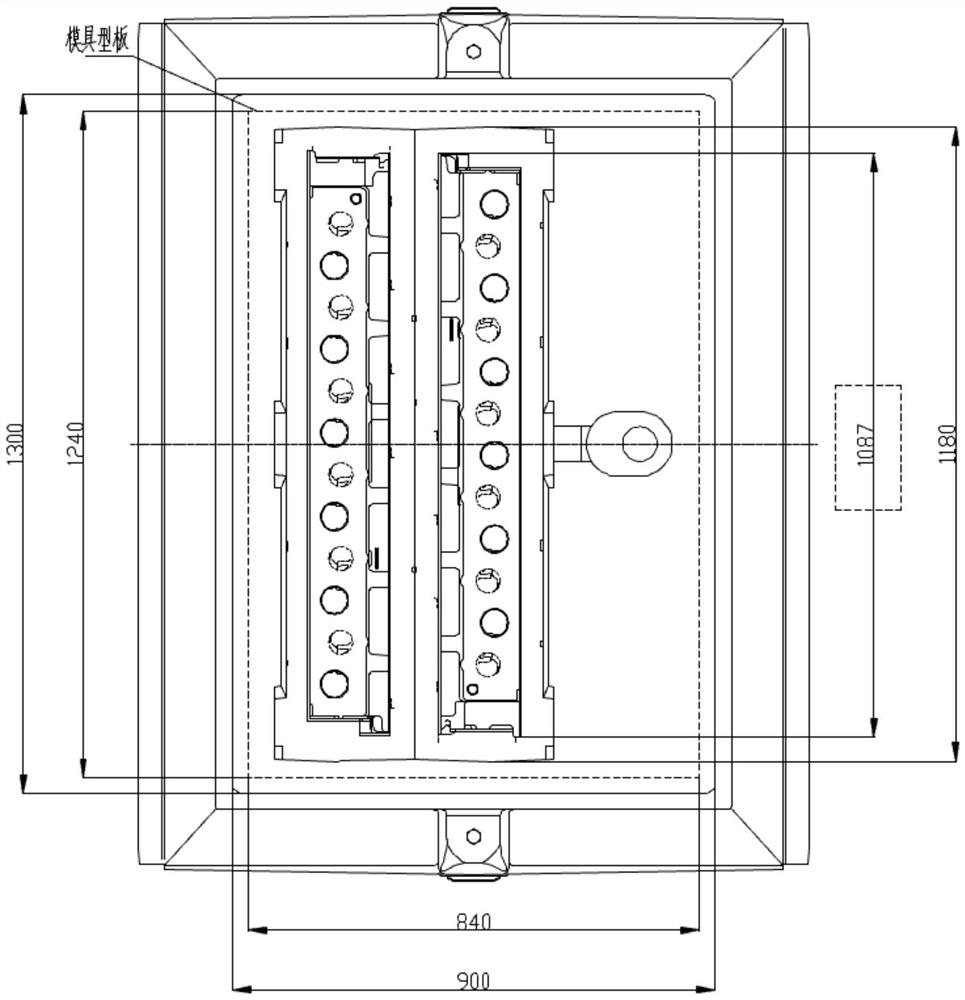

[0037] The cylinder head casting involved in the present invention has an outline size of 1217×400×136mm (length, width and height), and the shrinkage rate needs to be added during model design, and the size is 1232×404×138mm (length, width and height). The size of the foundry sand box is 1300×900×700mm (length, width and height), the size of the mold plate is 1240×840mm (length and width), and the length dimension margin is only 10mm. In addition, the thickness of the sand layer of the sand core needs to be considered. Can't produce by prior art scheme.

[0038] Under the conditions of the existing technical scheme, the maximum cylinder head casting size that can be produced is 1100×400mm (length and width), see figure 1 , figure 2 .

[0039] In the existing technical scheme, the length of the mold plate is 1240mm, and the length of the casting is 1087mm. In order to ensu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com