Assembly test platform

A test platform and mobile platform technology, applied in workbenches, manufacturing tools, etc., can solve problems such as low efficiency, complicated processes, and lack of assembly benchmarks, so as to improve work efficiency, reduce complicated processes, and save time and manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

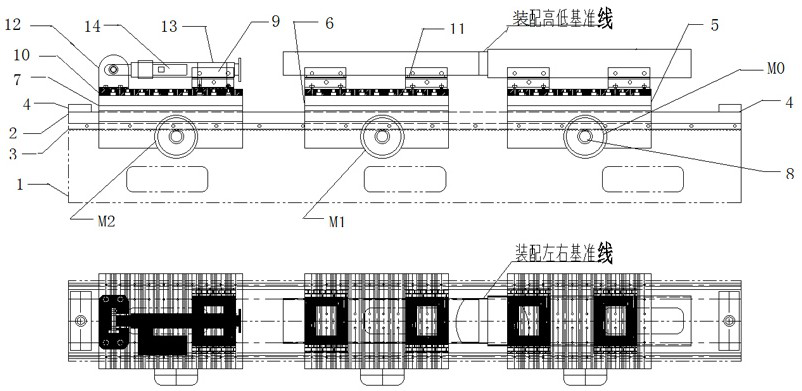

[0048] Such as Figure 1 to Figure 6 As shown, the assembly test platform of the present invention includes a guide rail base 1, and the guide rail base 1 is connected and fixed with the guide rail 2 by bolts, and a rack 3 is also arranged between the guide rail base 1 and the guide rail 2, and the guide rail 2 Limiting block 4 is set at the end, and the first mobile platform 5, the second mobile platform 6 and the third mobile platform 7 are sequentially arranged on the guide rail 2, and the first mobile platform 5, the second mobile platform 6 and the third mobile platform The bottom of the platform 7 is provided with a pair of drive gears 8, the drive gear 8 meshes with the rack 3, so that the first mobile platform 5, the second mobile platform 6, and the third mobile platform 7 can move horizontally on the guide rail base 1, The driving gear 8 is controlled and driven by a gear motor;

[0049] The first mobile platform 5, the second mobile platform 6 and the third mobile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com