Ship balancing system

A technology for balancing systems and ships, which is applied in the field of ships, and can solve problems such as cumbersome and complicated balancing systems, affecting ship costs, and easy duplication of pipelines and functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

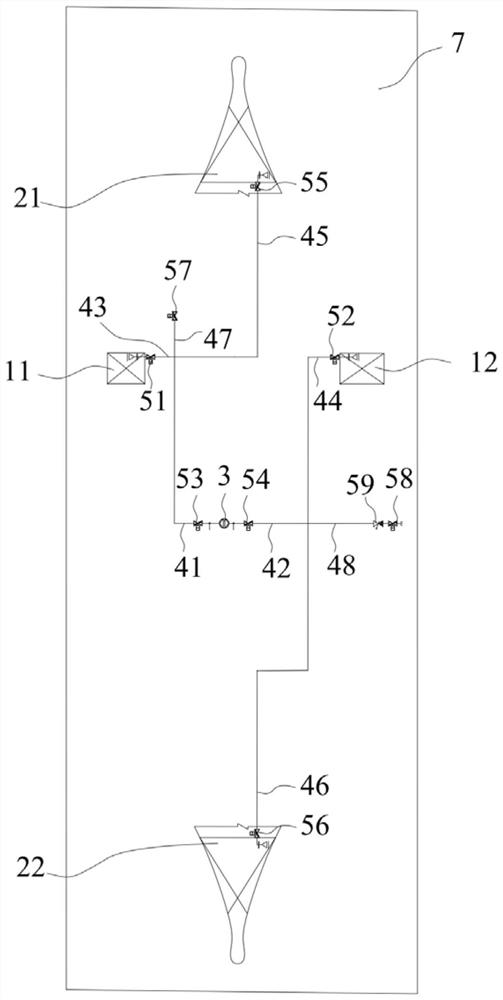

[0038] Such as figure 1 As shown, the present embodiment provides a ship balancing system, which includes a heel ballast tank, a trim ballast tank, a connecting pipe group, a regulating valve group and a tilting pump 3, and the heel ballast tank includes The port tank 11 and the starboard tank 12 on the body 7; the trim ballast tank includes a bow tank 21 and a stern tank 22 arranged on the ship body 7; The bow cabin 21 and the stern cabin 22 are respectively connected with a connecting end; the regulating valve group is connected to the connecting pipe group; the tilting pump 3 is connected to the connecting pipe group, and is used to drive the flow of ballast water in the connecting pipe group, and is adjusted by opening and closing. The valve group can make the tilting pump 3 communicate with the port tank 11 and the starboard tank 12 or the tilting pump 3 communicate with the bow tank 21 and the stern tank 22 .

[0039] The ship balance system provided by this embodiment ...

Embodiment 2

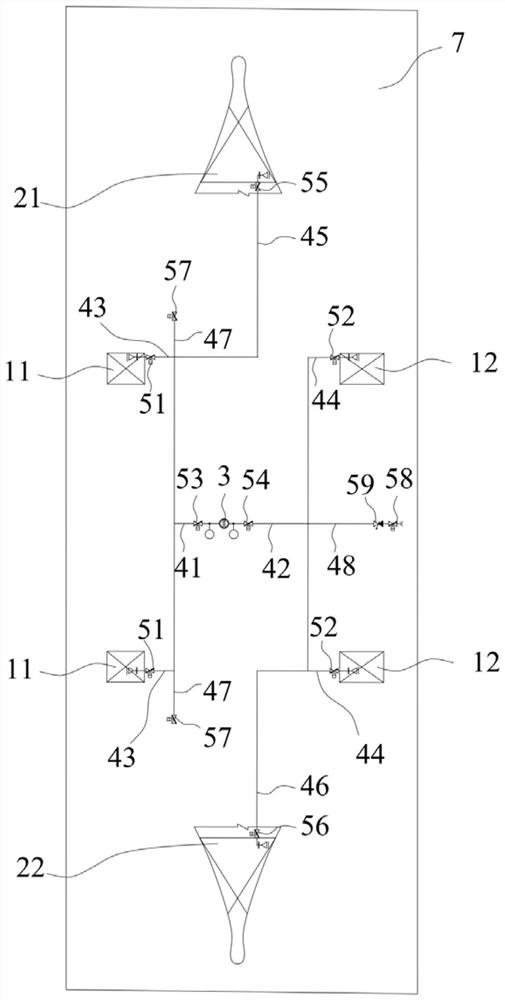

[0054] figure 2 Embodiment 2 is shown, in which components identical or corresponding to those in Embodiment 1 are identified with reference numerals corresponding to Embodiment 1. For the sake of brevity, only the difference between Embodiment 2 and Embodiment 1 will be described. The difference is that this embodiment is provided with two groups of heeling ballast tanks, and each group of heeling ballast tanks includes a port tank 11 and a starboard tank 12. Two groups of heeling ballast tanks are arranged at intervals along the fore and aft direction of the ship body 7, wherein each port tank 11 communicates with the first connection end through a port pipe 43, and each port pipe 43 is provided with a port valve 51 , correspondingly, each starboard tank 12 is communicated with the second connecting end through a starboard pipe 44, and each starboard pipe 44 is provided with a starboard valve 52, and the port tank 11 and the starboard tank 12 of each group of heeling ballas...

Embodiment 3

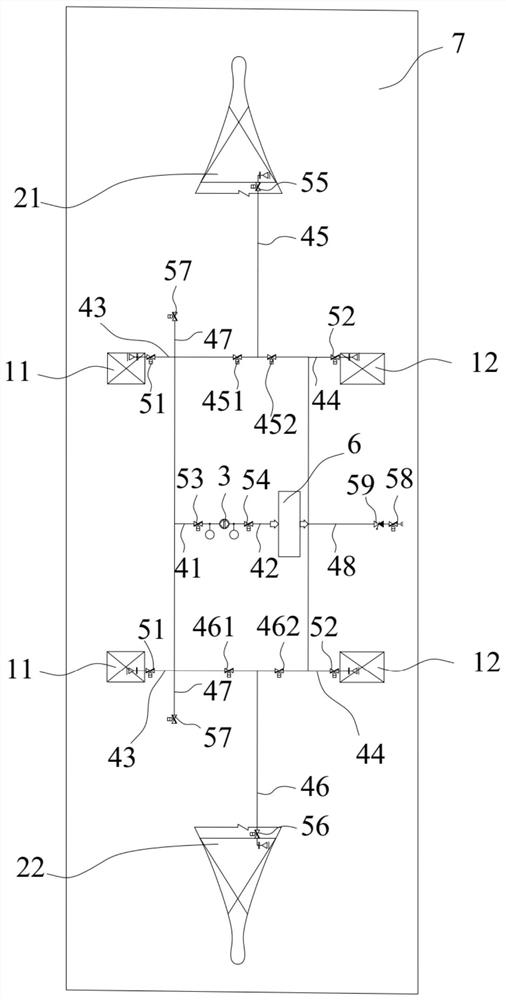

[0061] image 3 Embodiment 3 is shown, in which components identical or corresponding to those in Embodiment 2 use reference numerals corresponding to Embodiment 2. For the sake of brevity, only the difference between Embodiment 3 and Embodiment 2 will be described. The difference is that the head pipe 45 connecting the bow cabin 21 is communicated with two branches, and the two branches are connected to the first connection end and the second connection respectively. At the connection end, a first branch valve 451 and a second branch valve 452 are respectively arranged on the two branches. The settings of the first branch valve 451 and the second branch valve 452 are used to control the communication between the fore tank 21 and the first connection end or the second connection end. Correspondingly, the stern pipe 46 connected to the stern compartment 22 is communicated with the first connection end and the second connection end respectively through two branches, and the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com