Method andapparatus for pouring bulk material in bags at port

A technology of bag filling and equipment, which is applied in the field of port bulk cargo bag filling methods and equipment, can solve the problems of multiple auxiliary equipment, slow flow rate of bag filling goods, crowded work site, etc., and achieve simplified operation process, high operation efficiency and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

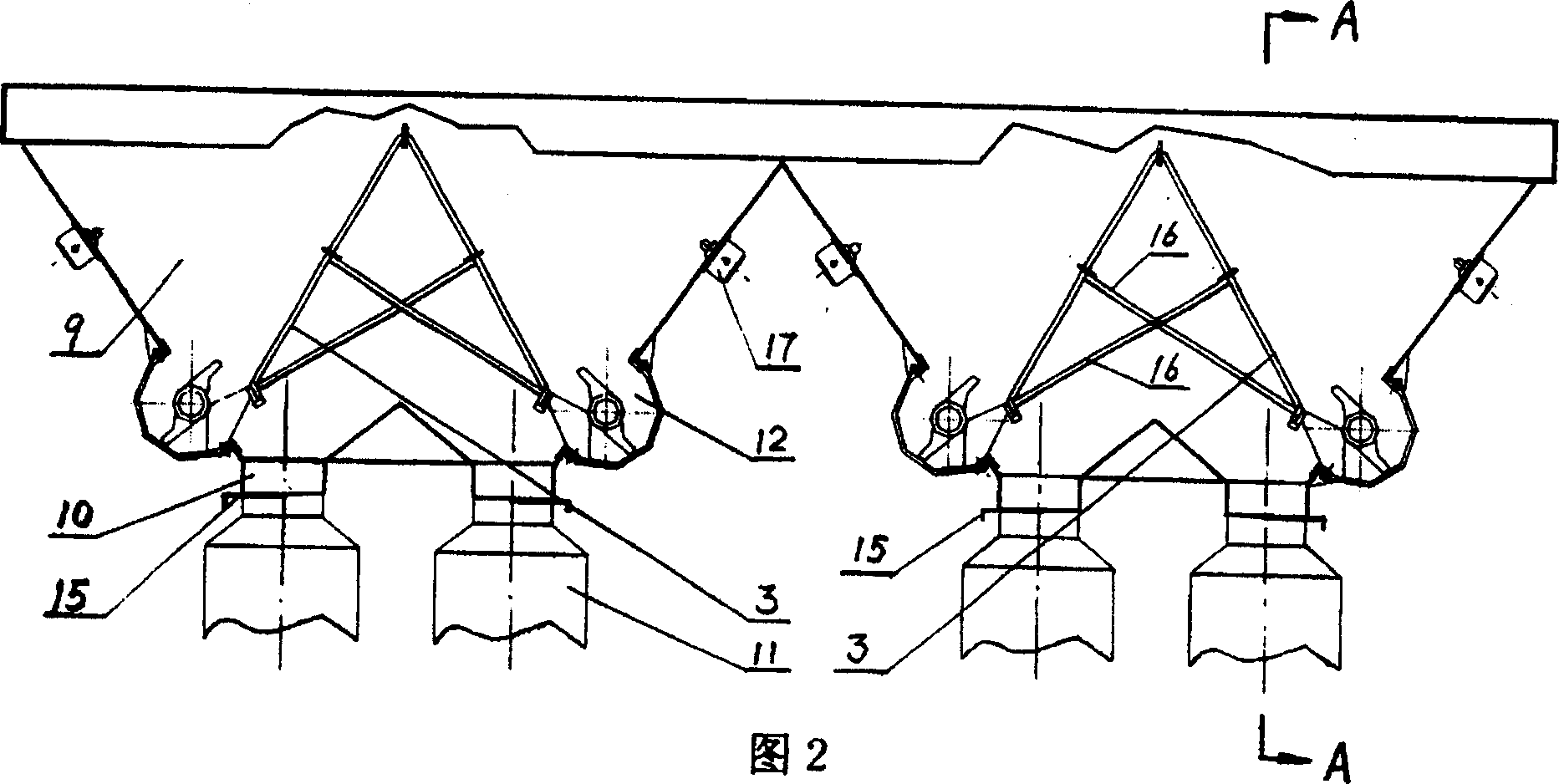

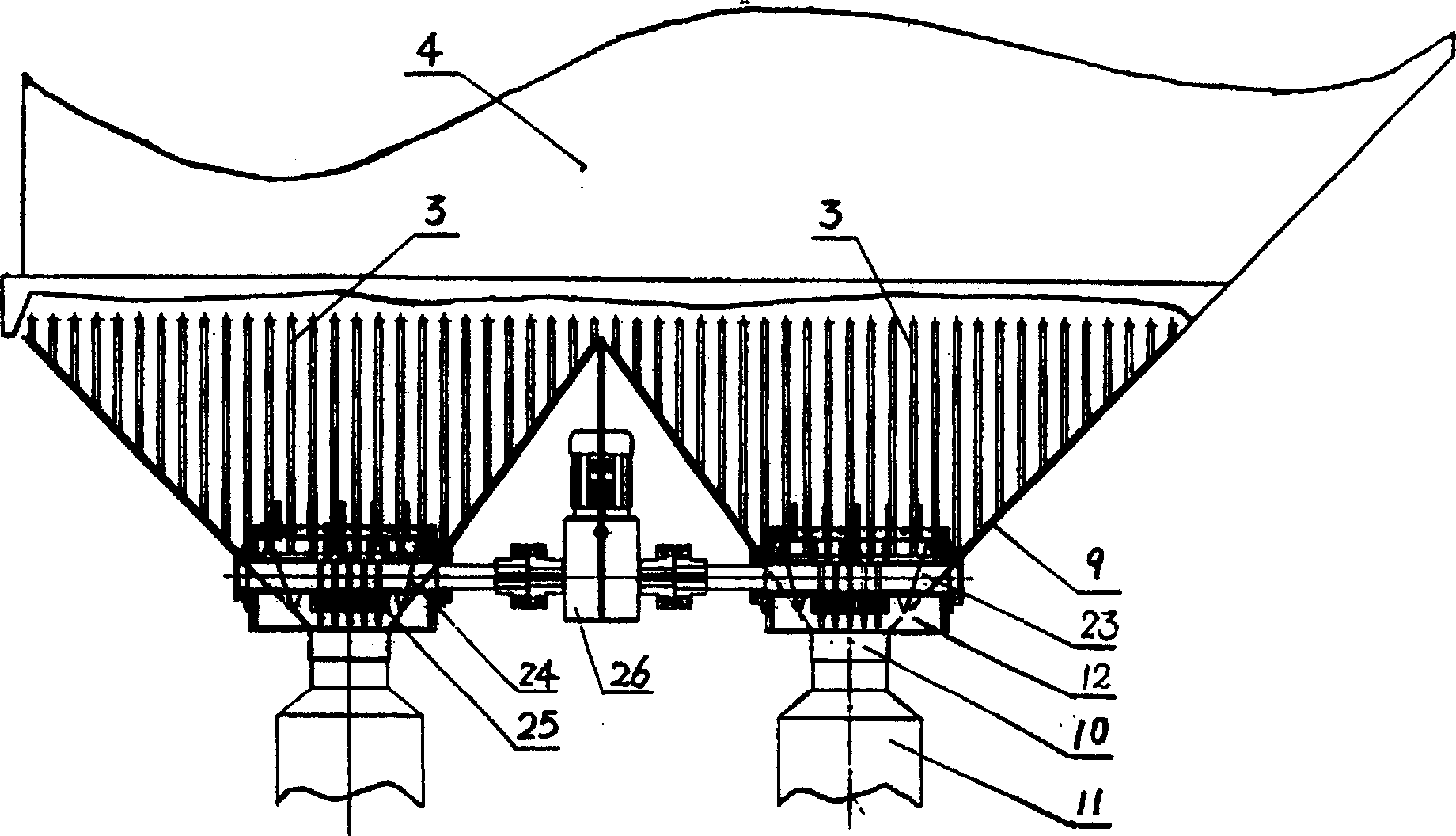

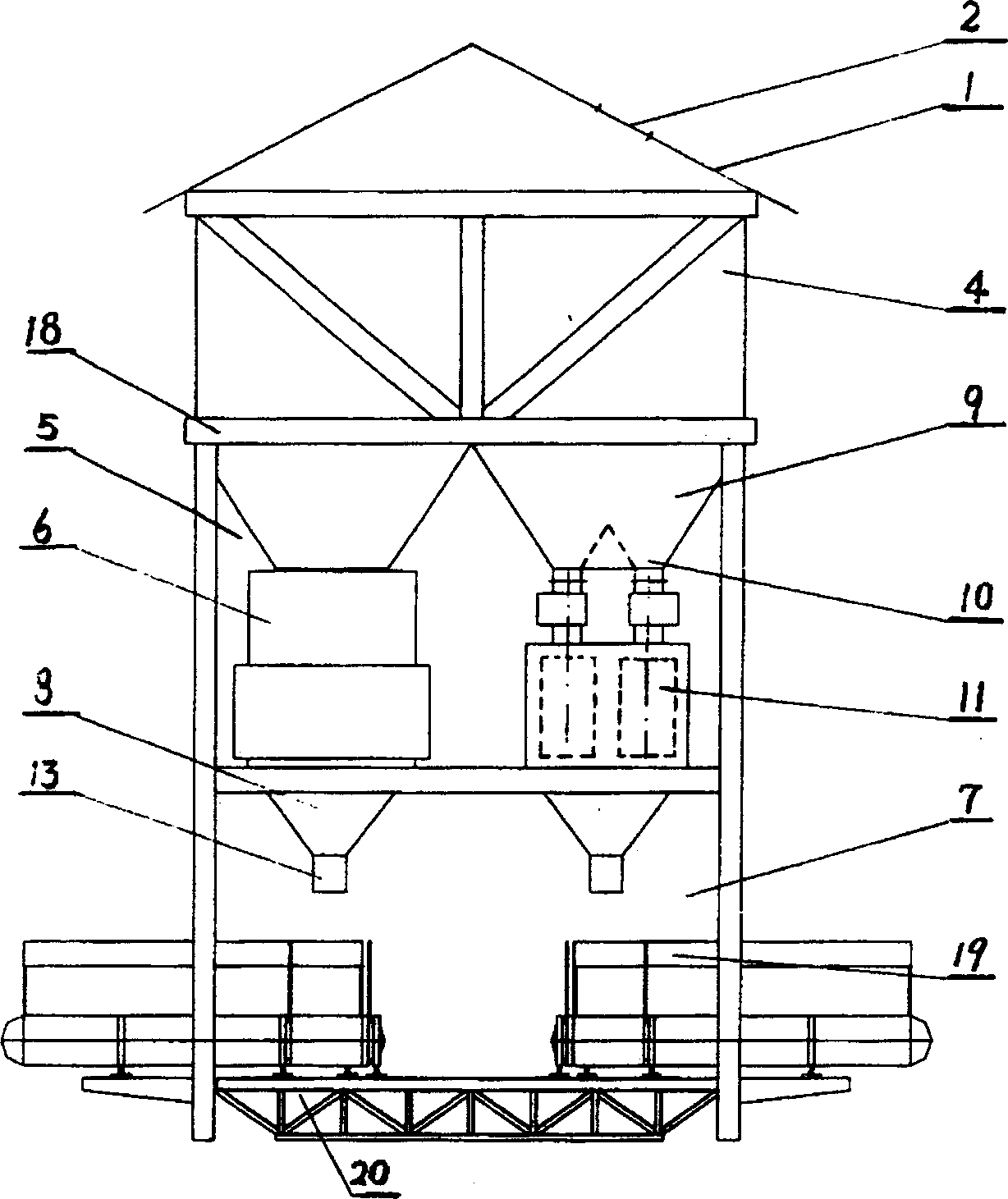

[0014] Such as figure 1 As shown, the overall structure of the bag filling machine of the present invention adopts a movable integrated frame structure. Using double forklift shoveling mobile mode. The overall structure is divided into three parts, the upper part is the collecting bin layer, including the airtight cover 1, the feeding port 2, the material filter 3, the collecting hopper 4, the middle part is the control room 5, including the electronic weighing scale 6 and its control cabinet, air Compressor and its control cabinet, dryer, electrical control cabinet, the lower part is the bag filling operation room 7, including the discharge buffer bucket 8, bag clamp, bag sewing machine 21, material horizontal conveyor 19, operation platform 20 and on-site operation Control cabinet. Such as Figure 4 Shown, the feature of the present invention is that said collection hopper 4 is a square open shape hopper, and its lower part is divided into 4 lower hoppers 9, and each lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com