Goods delivery system and method for high-rise building

A technology for high-rise buildings and buildings, which is applied to elevators, conveyors, conveyor objects, etc. in buildings, and can solve problems such as failure to deliver goods to the door, elevator congestion, and affecting staff going downstairs, so as to avoid occupying elevators resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

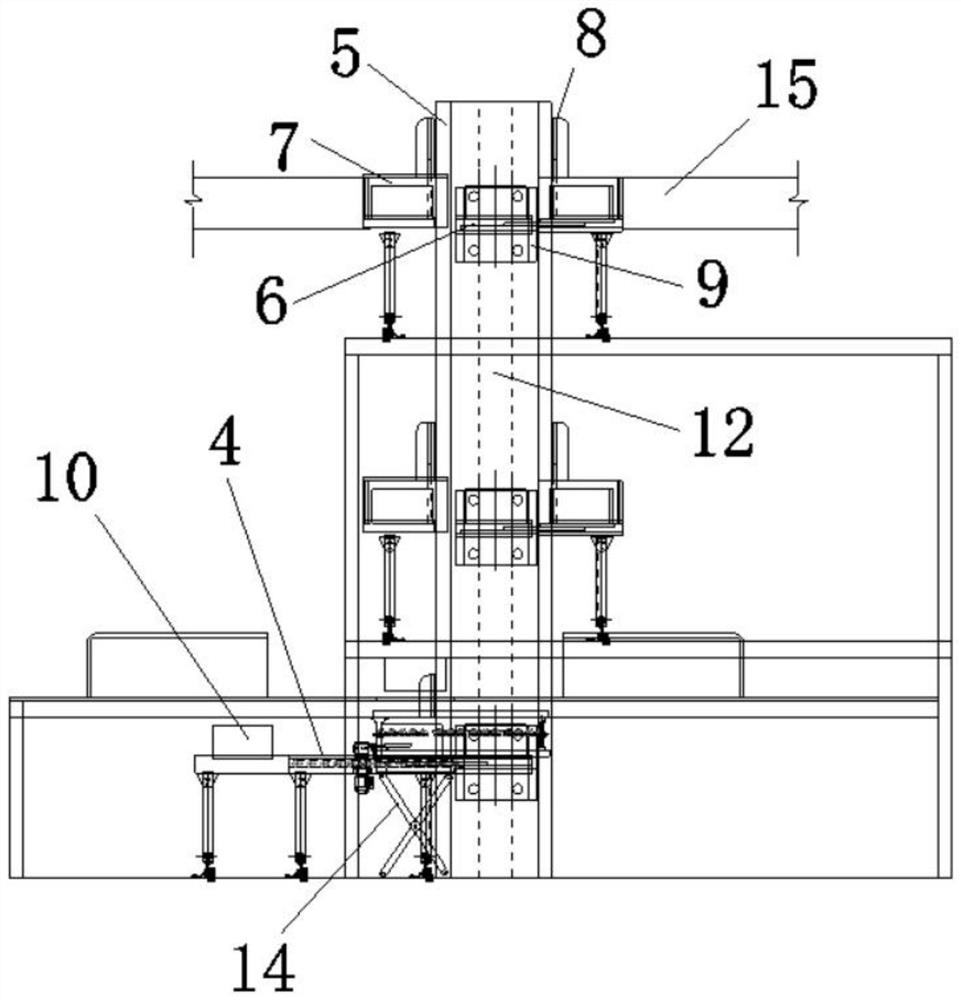

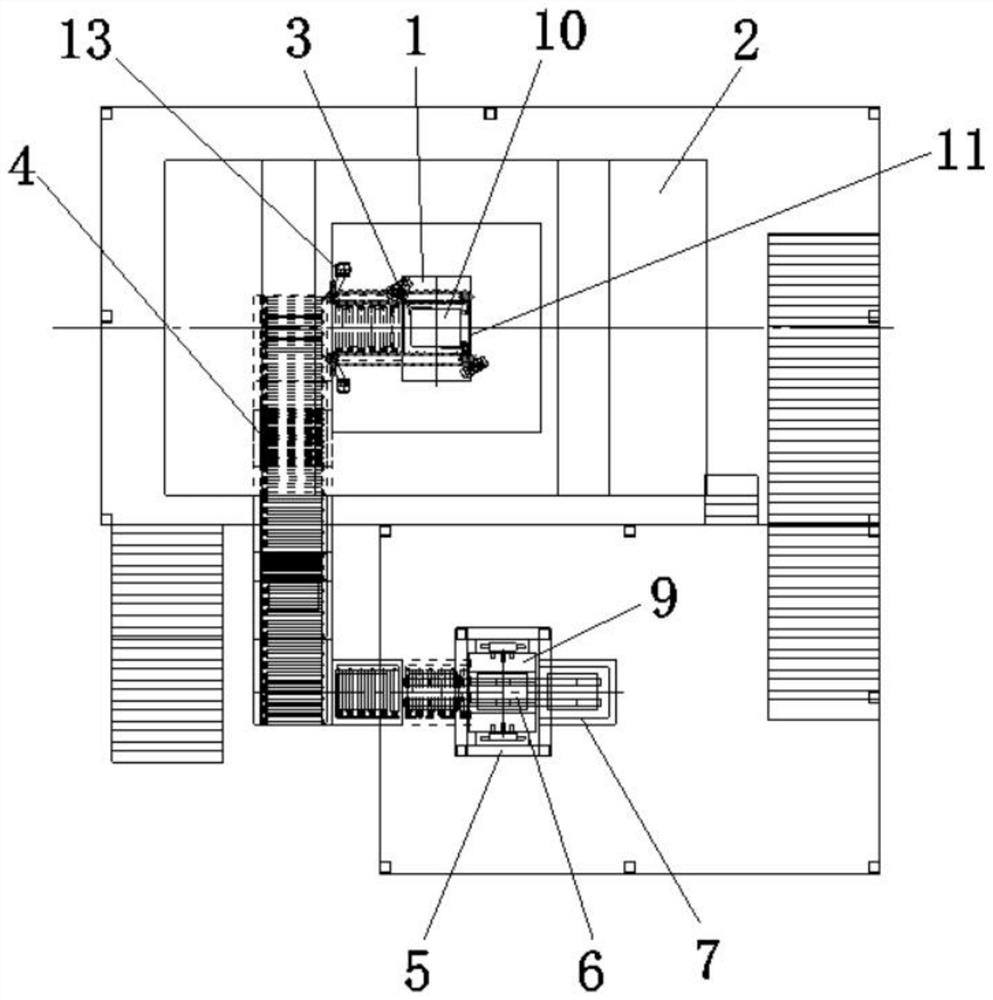

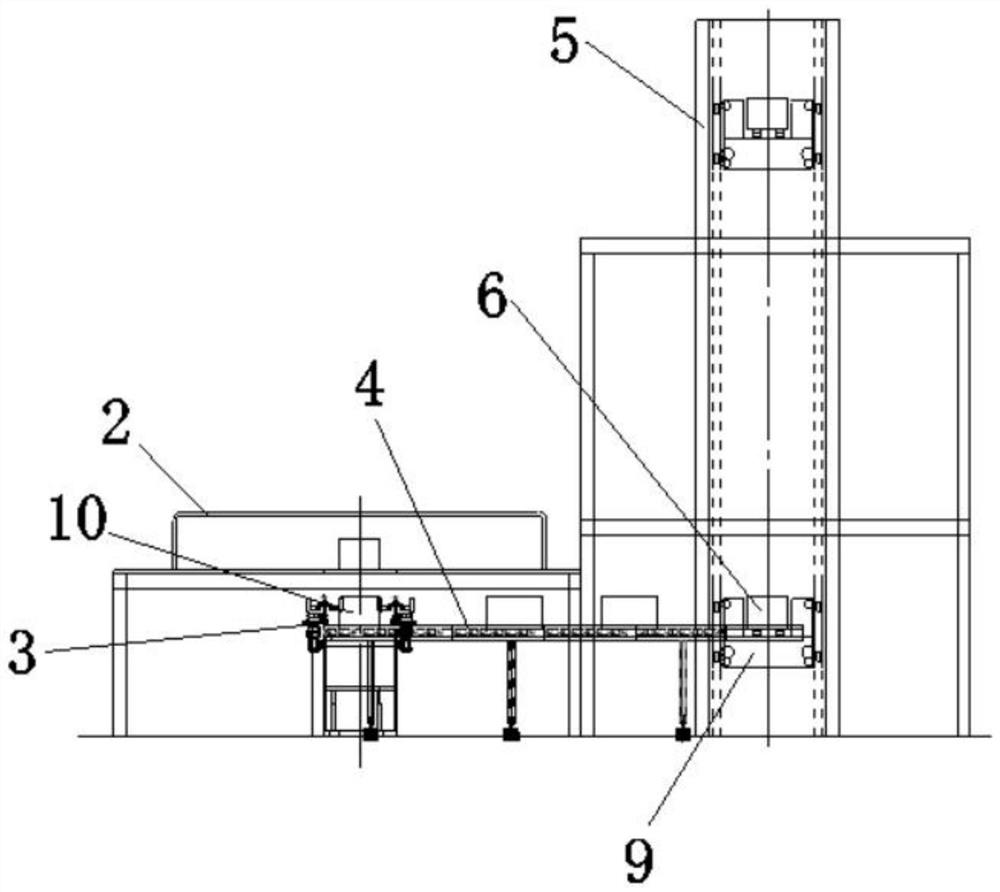

[0020] Embodiment of the present invention: a structural schematic diagram of a cargo delivery system for high-rise buildings is as follows Figure 1~3 As shown, it includes a cargo receiving port 11 opened on the top floor, bottom floor or terrace of the building and a cargo delivery shaft 5 running through the interior of the building. A conveying line 4 is connected between the cargo receiving port 11 and the cargo delivery shaft 5. A loading platform 1 is installed at the cargo receiving port 11, a standard container 10 is placed on the loading platform 1, a scissor lift 14 is installed at the bottom of the loading platform 1, and guide rails are fixedly installed in the cargo delivery shaft 5 12. An elevator 9 is slidably connected to the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com