Secondary profiling blank preparation device and blank preparation method

A preparation device and secondary pressing technology, which is applied in glass pressing, glass manufacturing equipment, feeding trough, etc., to achieve the effect of improving the production efficiency of pressing and reducing the glass dividing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

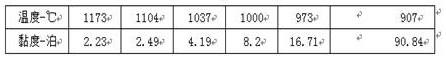

[0028] Example: A certain brand of optical glass has a refractive index of 1.72000, an Abbe number of 50.34, and a specific gravity of 3.87 grams per cubic centimeter. The viscosity-temperature corresponding data of glass liquid is as follows:

[0029]

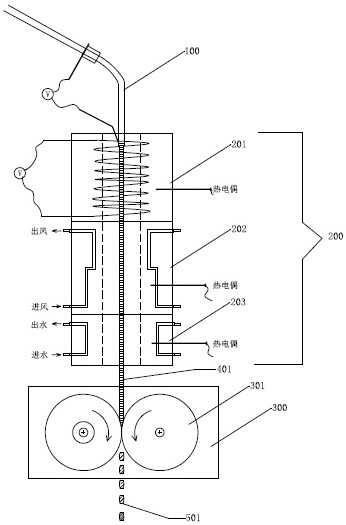

[0030] The process of preparing an optical glass blank by using the device and method of the invention is as follows:

[0031] After the glass raw material is smelted and homogenized in the furnace, it flows out through the furnace leakage pipe 100. The diameter of the furnace leakage pipe 100 is calculated to match the unit discharge volume. By controlling the temperature of the leakage pipe, the glass can flow out of the kiln. The viscosity is about 10 poise when the leakage material pipe 100 of the furnace flows out. The glass liquid of this brand flows into the glass viscosity regulating forehearth 200 through the leakage pipe 100 of the kiln. The cooling temperature of the third cavity forehearth 203 is about 60° C.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com