Spray tower with gas flow equalizing device

A technology of spray tower and gas, which is applied in the field of spray tower, achieves the effect of uniform spray area, little influence of flow uniformity, and solution to the problem of uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

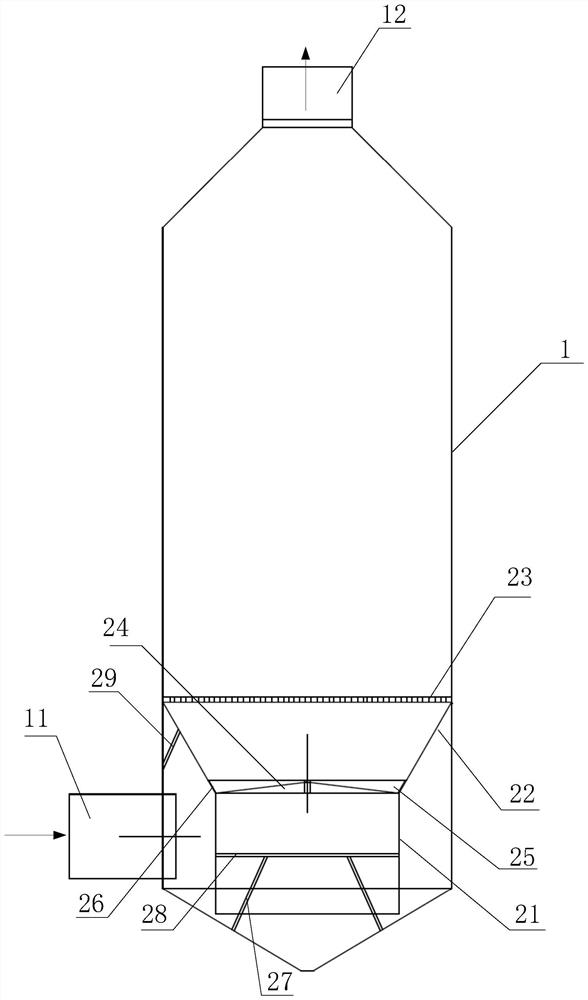

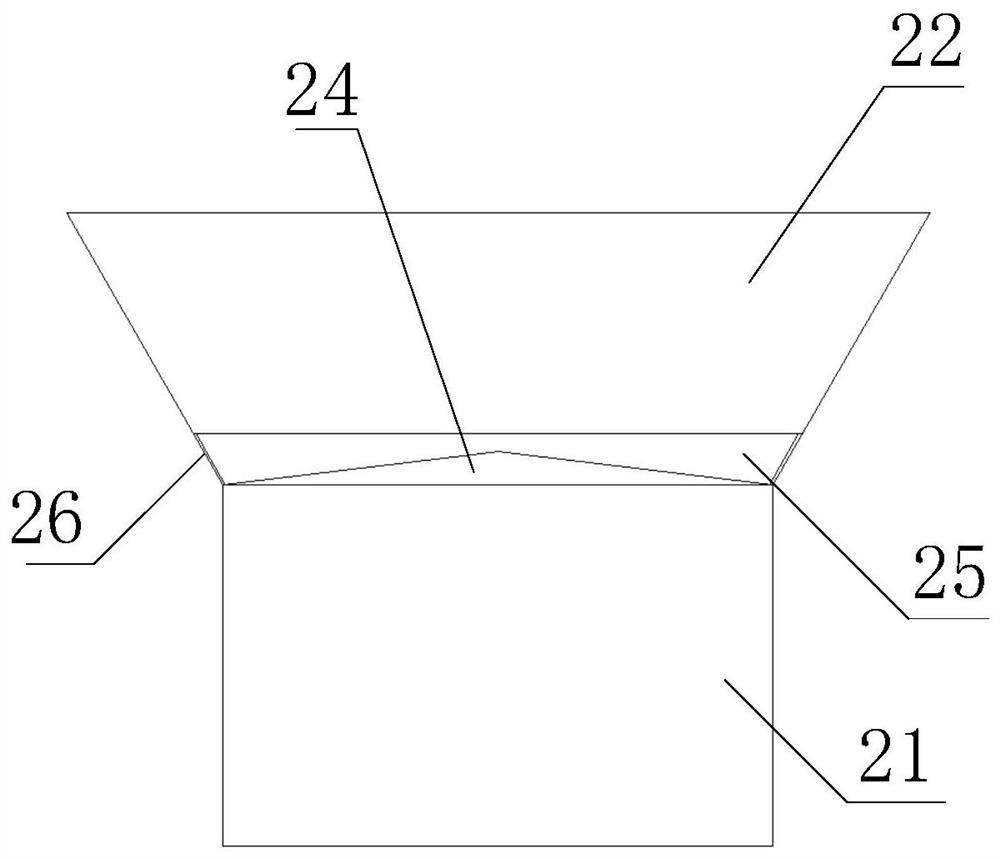

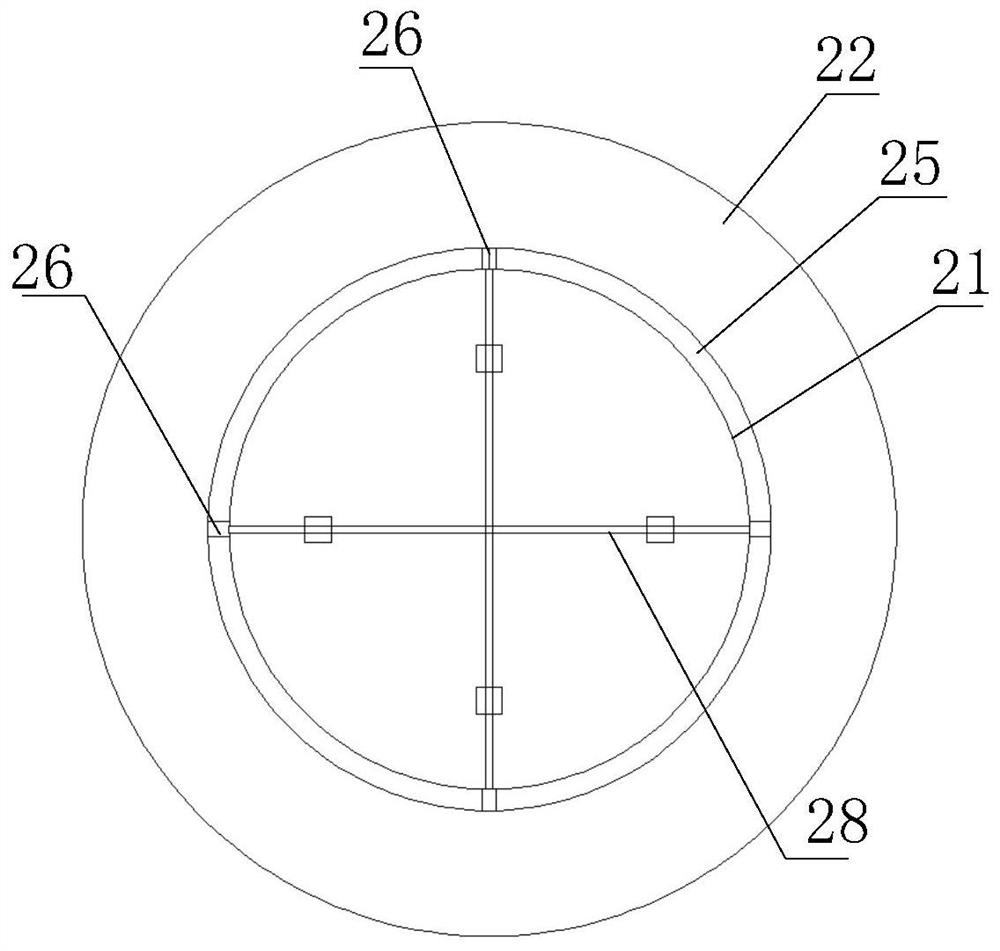

[0030] like Figure 1 to Figure 4 As shown, a spray tower with a gas equalizing device illustrated in this example includes a spray tower 1, the side of the lower part of the spray tower 1 is provided with one or more gas inlets 11, and the top of the spray tower 1 is provided with There is a gas outlet 12, and the top of the spray tower 1 is provided with a spray gun for spraying (not shown); it also includes a gas equalizing device arranged at the bottom of the spray tower 1, and the gas equalizing device includes a circular guide tube 21 and a cone Shape guide tube 22, wherein, the inner cavity of circular guide tube 21 is closed in the circumferential direction, and the annular flow equalization zone is formed between the side wall of this circular guide tube 21 and the tower wall of spray tower 1, described The gas inlet 11 is set on the wall of the spray tower 1 corresponding to the annular flow equalization area (that is, the vertical position of the circular guide tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com