Spindle pot bearing

A bobbin cup and bobbin technology, applied in the field of bearing bushing, bobbin cup seat of two-for-one twister or direct twister, can solve the problems of bobbin cup damage, twisting interruption, etc., and achieve the effect of reliable avoidance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

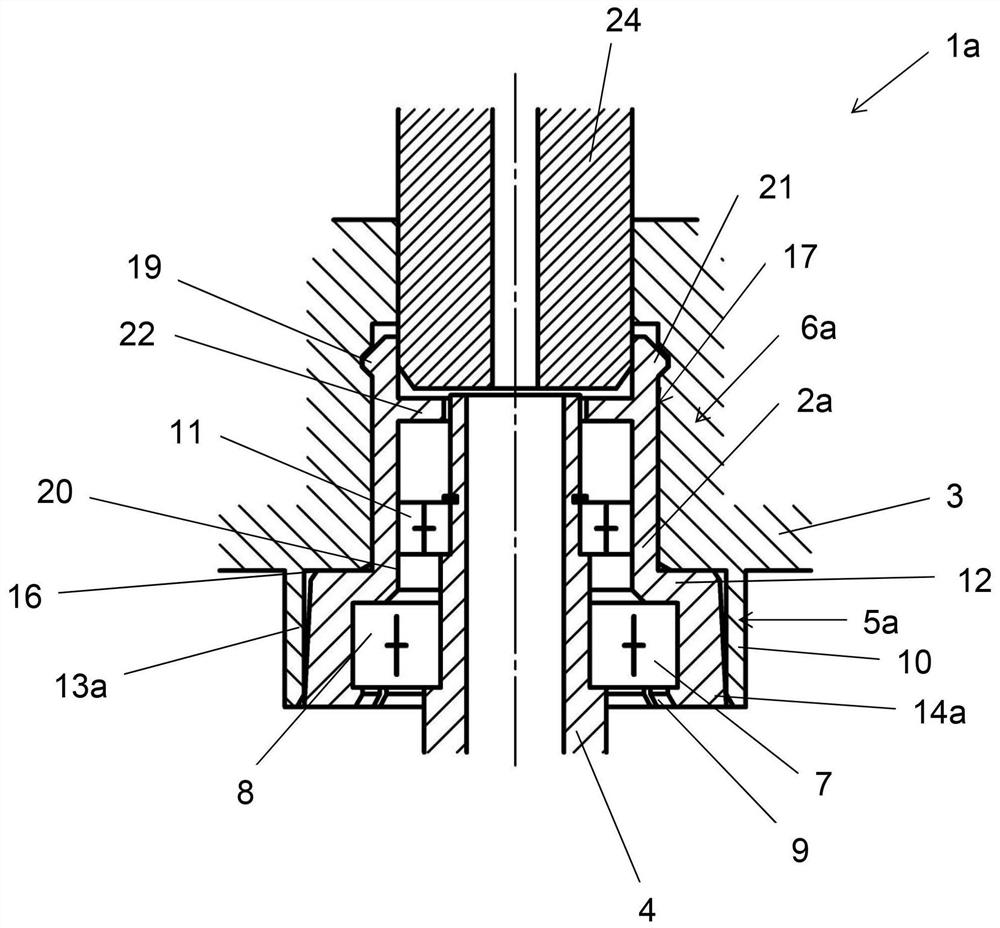

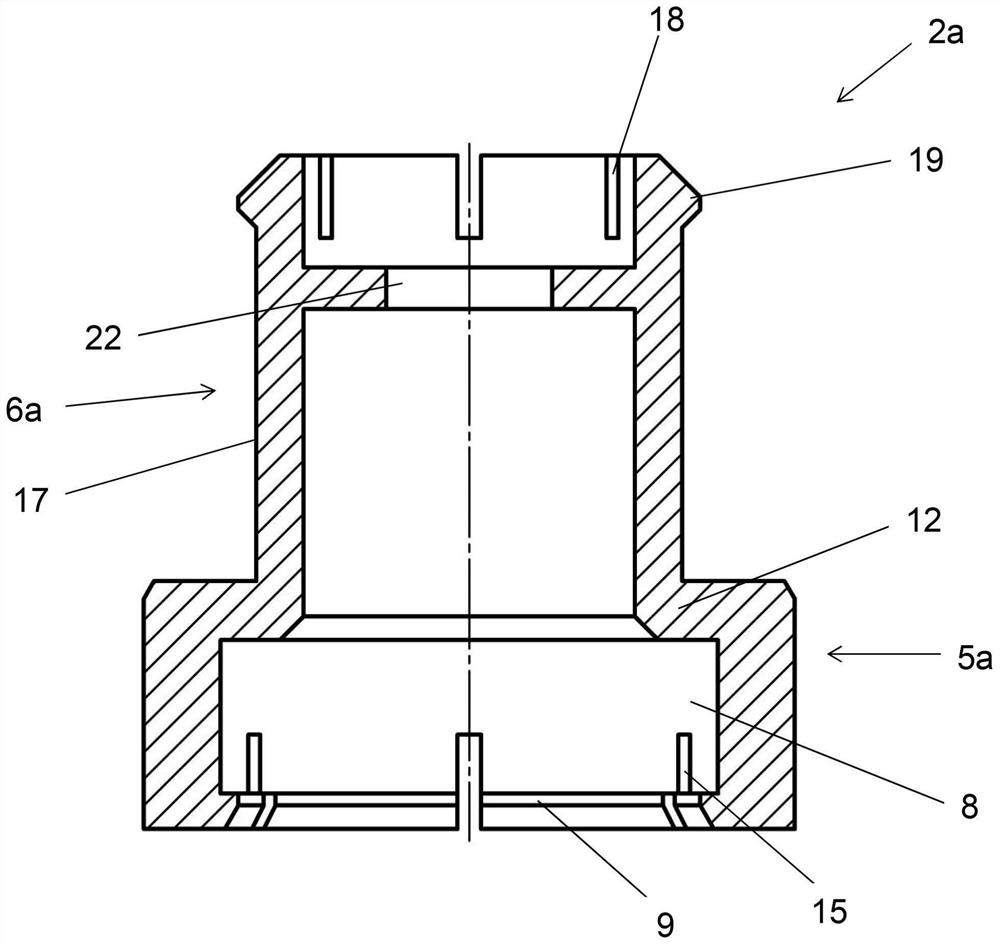

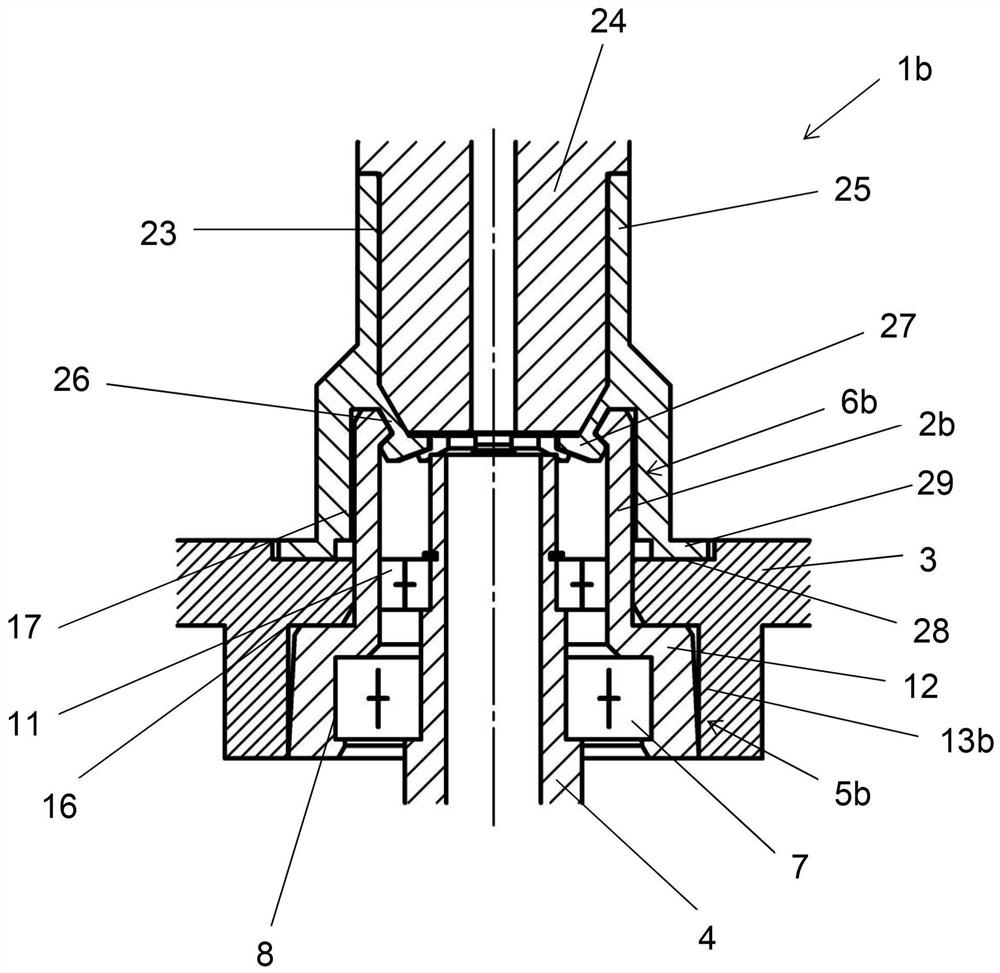

[0089] exist figure 1 is shown consisting of bobbin cup bottom 3 and as figure 2 The shown bearing bushing 2a makes the bobbin cup holder 1a. The bearing bush 2a has, for its rotatable connection to the first bearing part 7 and the second bearing part 11 of the spindle 4, a first bearing part 5a for connecting to the first bearing part 7 and a first bearing part 5a for connecting to the second bearing part. 11 of the second support portion 6a. in such as figure 1 In the illustrated operating position in which the bearing bushing 2 a is positively connected axially to the first bearing part 7 , the first bearing part 5 a bears against the top surface of the first bearing part 7 with the shoulder 12 .

[0090] In order to fix the bearing bush 2a after it is inserted into the bearing parts 11, 7 such as figure 1 In the shown working position, the first bearing part 5a has, at its end opposite the second bearing part 6a, a locking projection 9 protruding from the inner surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com