Ballastless track measuring method and device

A ballastless track and measurement method technology, applied in tracks, measuring instruments, track maintenance, etc., can solve problems such as low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The embodiment of the invention provides a ballastless track measuring method and device thereof.

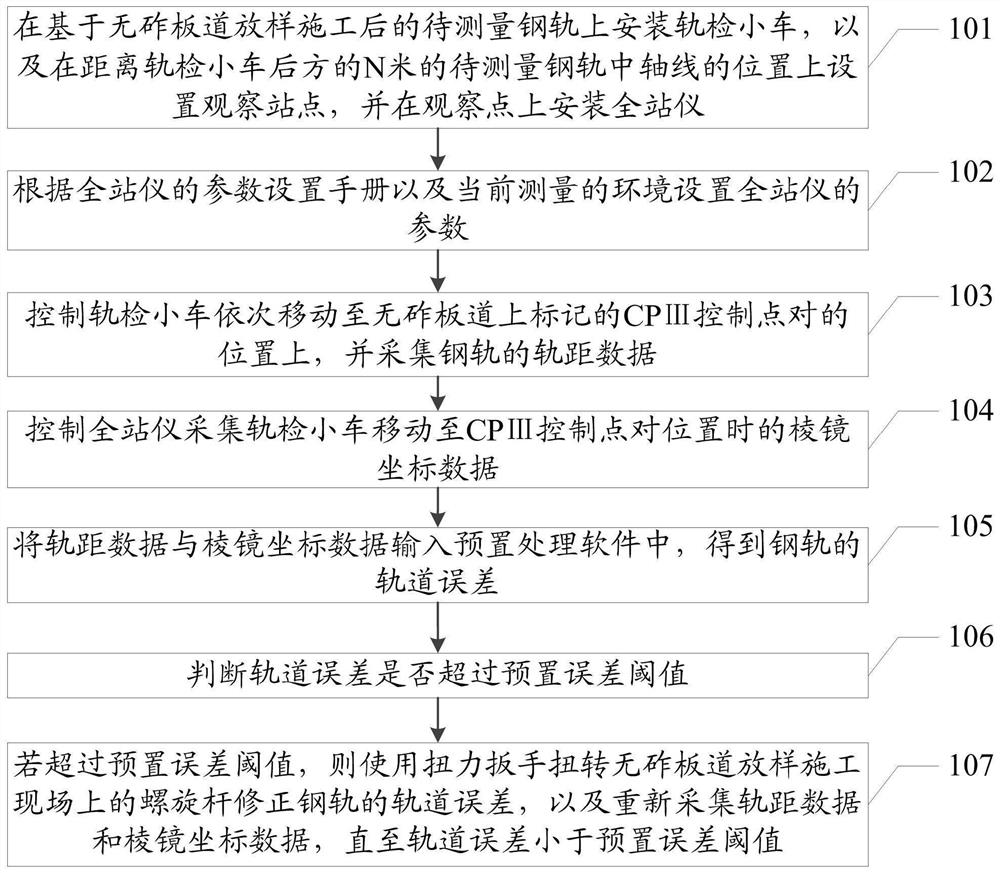

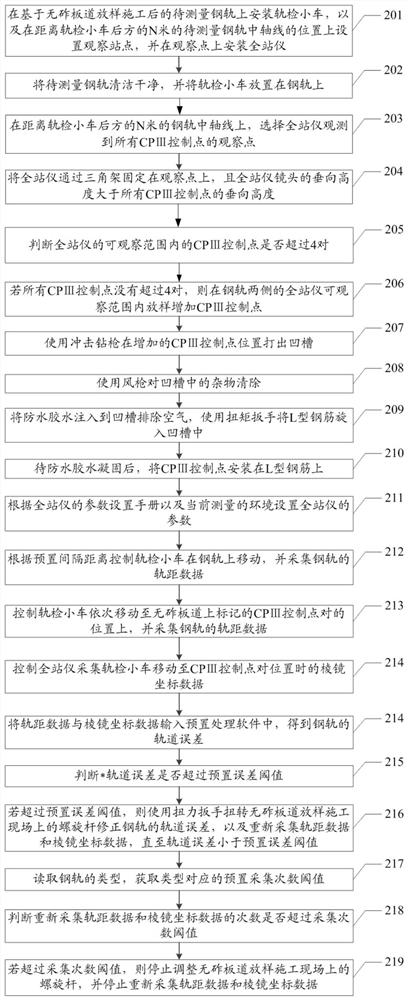

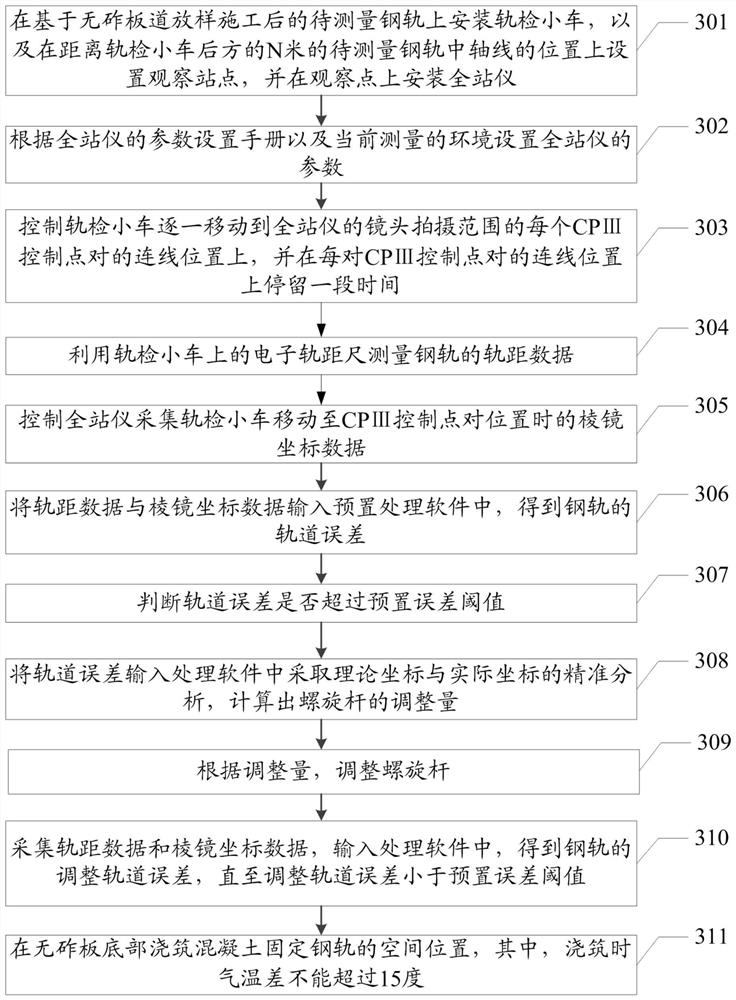

[0057] In the technical solution provided by the present invention, a rail inspection trolley is installed on the rail to be measured based on the lofting construction of the ballastless slab, and an observation is set at the position of the central axis of the rail to be measured N meters behind the rail inspection trolley. site, and install a total station on the observation point, wherein, N is a natural number; set the parameters of the total station according to the parameter setting manual of the total station and the current measurement environment, wherein the parameters include : temperature, air pressure, temperature; control the track inspection trolley to move to the position of the CPIII control point pair marked on the ballastless slab track in sequence, and collect the gauge data of the rail, wherein, on the ballastless slab track The interval distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com