Water surface floating object collecting device

A technology for collecting floating objects on the water surface, which is applied to the cleaning of open water surfaces, water conservancy projects, construction, etc., can solve the problems of inconvenient collection of floating objects on the water surface, and achieve the effects of high work efficiency, simple collection work, and fast collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

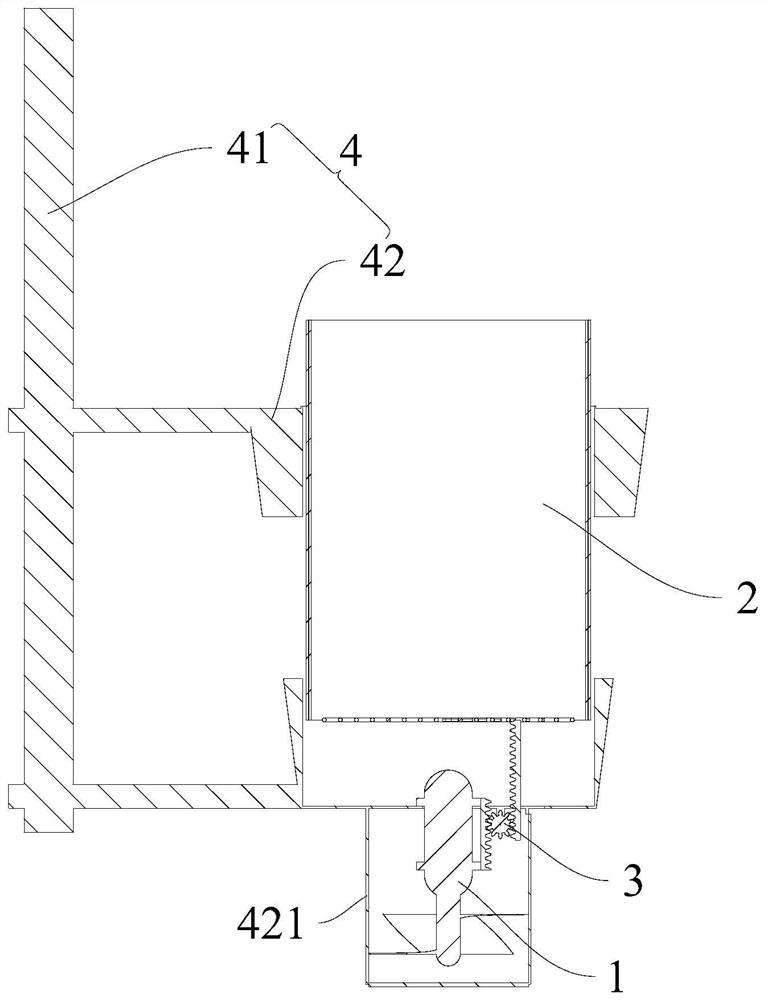

[0059] Such as Figure 1-4 As shown, the present invention provides a water surface floating object collection device, which includes a drainage mechanism 1, a collection bucket 2, a movement mechanism 3, and a fixing mechanism 4. The fixing mechanism 4 includes a fixed bracket 41 and is fixed on one side of the fixed bracket 41 The support assembly 42 includes two ring structures sleeved on the outside of the collection bucket 2, wherein the ring structure at the lower end is also fixed with a movement mechanism 3, and the drainage mechanism 1 is located below the movement mechanism 3 and passes through the movement mechanism 3 is connected to the collection bucket 2, such as figure 1 Shown.

[0060] When the drainage mechanism 1 is activated and the water above it is discharged downward, the drainage mechanism 1 moves upward by the reaction force of the water and drives the movement mechanism 3 to start working. The structure of the movement mechanism 3 is as follows Figure 4 S...

Embodiment 2

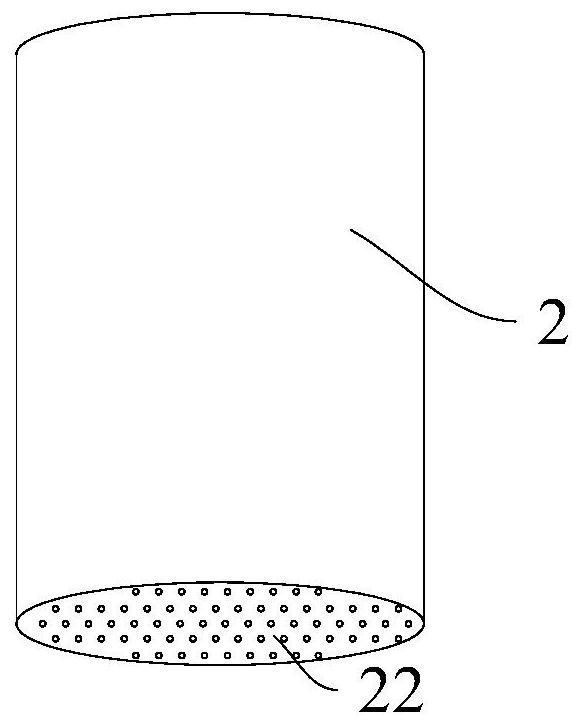

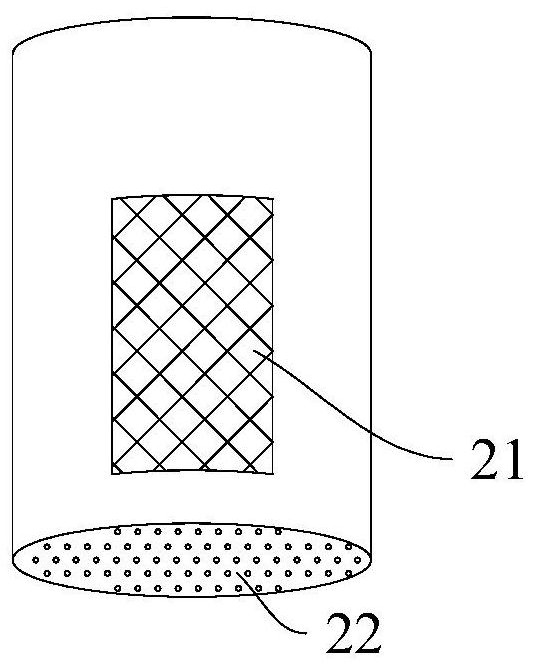

[0063] Such as Figure 5 As shown, the difference between this embodiment 2 and embodiment 1 is that the support assembly 42 in the water surface float collection device is a hollow columnar structure. When the drainage mechanism 1 is activated, the drainage mechanism 1 can only be located in the support assembly 42 And the water in the collection bucket 2 is discharged downwards, and the water in the surrounding environment will not be sucked. Therefore, compared with Embodiment 1, the working efficiency of the device can be greatly improved.

Embodiment 3

[0065] Such as Figure 6-7 As shown, the difference between the third embodiment and the second embodiment is that the structure of the movement mechanism 3 in the water surface floating object collection device is changed, which is caused by Figure 5 The rack and pinion meshing structure in Figure 7 The fixed pulley structure shown.

[0066] Specifically, the movement mechanism 3 includes a pulley 34 and a connecting belt 35 connected to the pulley 34. The pulley 34 is fixedly arranged on the support assembly 42. Both ends of the connecting belt 35 extend in the same direction and are respectively connected to the collection bucket 2 and the drainage mechanism 1. Connected.

[0067] It should be noted that the axis of the pulley 34 is always below the two ends of the connecting belt 35.

[0068] When the drainage mechanism 1 is activated, the drainage mechanism 1 itself will move upward under the action of the reaction force. At this time, the position of the pulley 34 is fixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com