Down selection machine

A technology of selecting machine and velvet, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of high facility cost, complex structure, high maintenance cost, etc. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

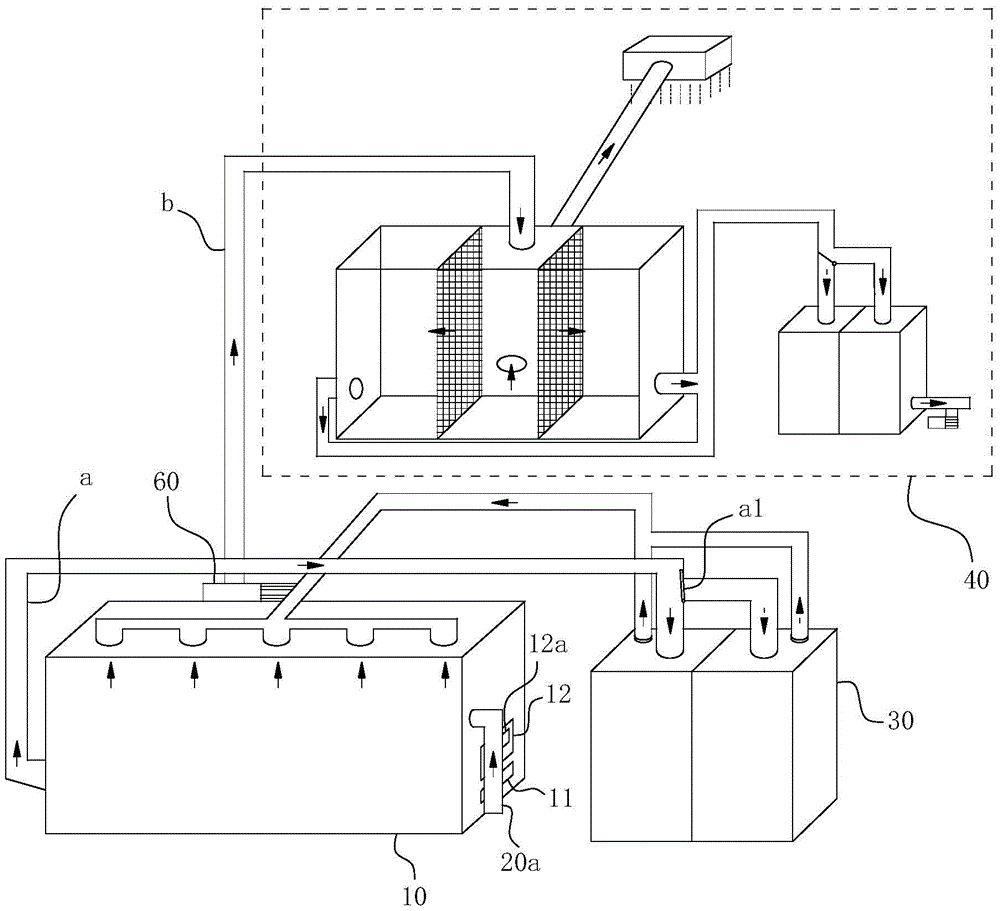

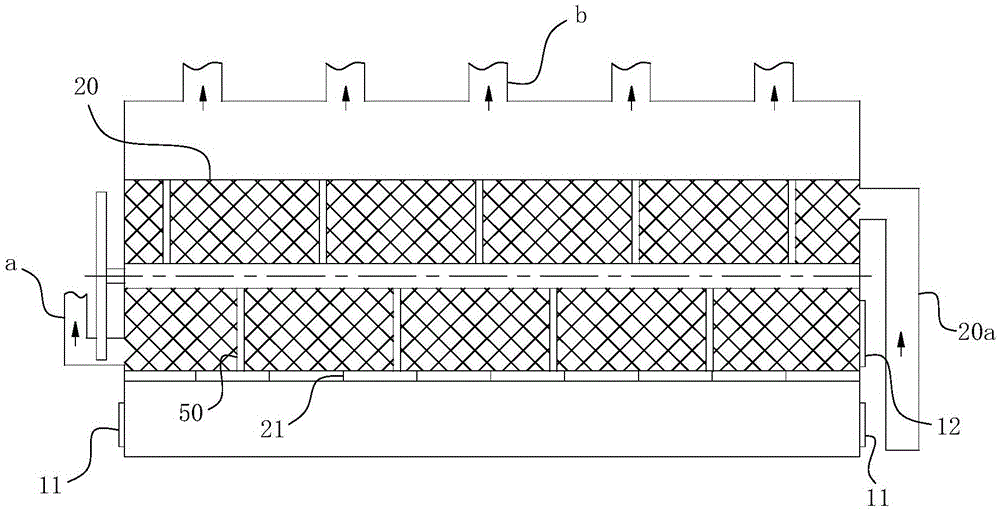

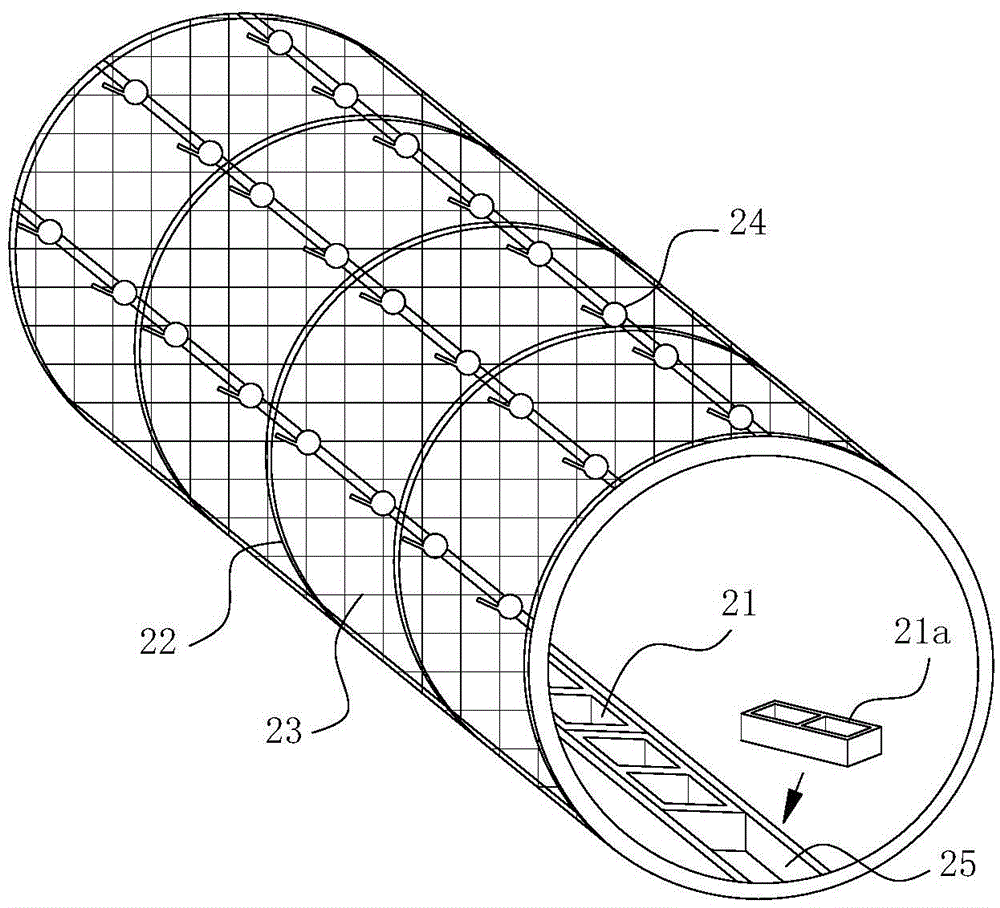

[0036] For ease of understanding, here is combined with the attached Figure 1-6 The specific implementation structure and work flow of the present invention are described in detail as follows:

[0037] System reference for specific implementation of the present invention figure 1 As shown, it includes the coarse down as the raw material to the selection step, and then the selection of large and small down flowers, and finally the entire selection and collection process of the corresponding down flowers. The specific structure of the present invention includes: a pile box 10 as a selection operation platform. The pile box 10 is divided into a feed cavity and a small pile cavity; the feed cavity consists of a cylindrical tube screen with a closed cavity environment 20, the two ends of the cylindrical screen portion 20 are respectively fixedly connected to the inner walls of the two opposite sides of the rectangular pile box 10; the connecting channel between the feeding cavity and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com