Rotary atomizer applied to new energy electrode material drying

A technology of rotary atomizer and electrode material, which is applied in the directions of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of inconvenient cables, traction connections, and complicated wiring assembly of the body, so as to improve the fixed the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

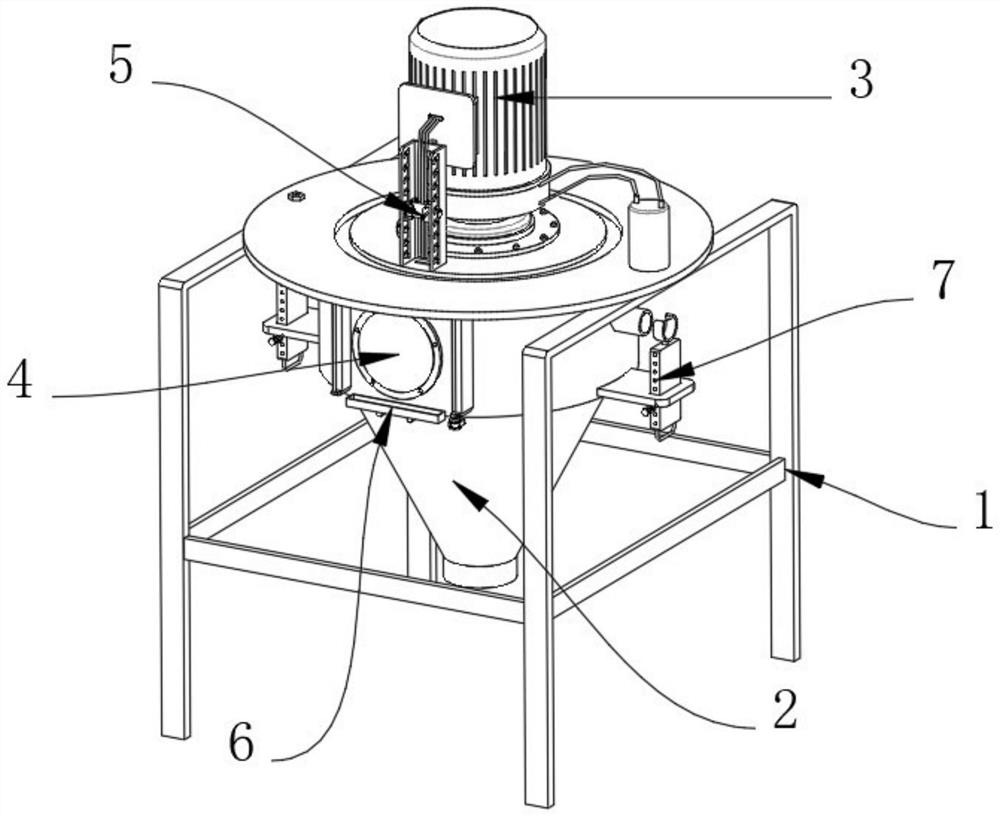

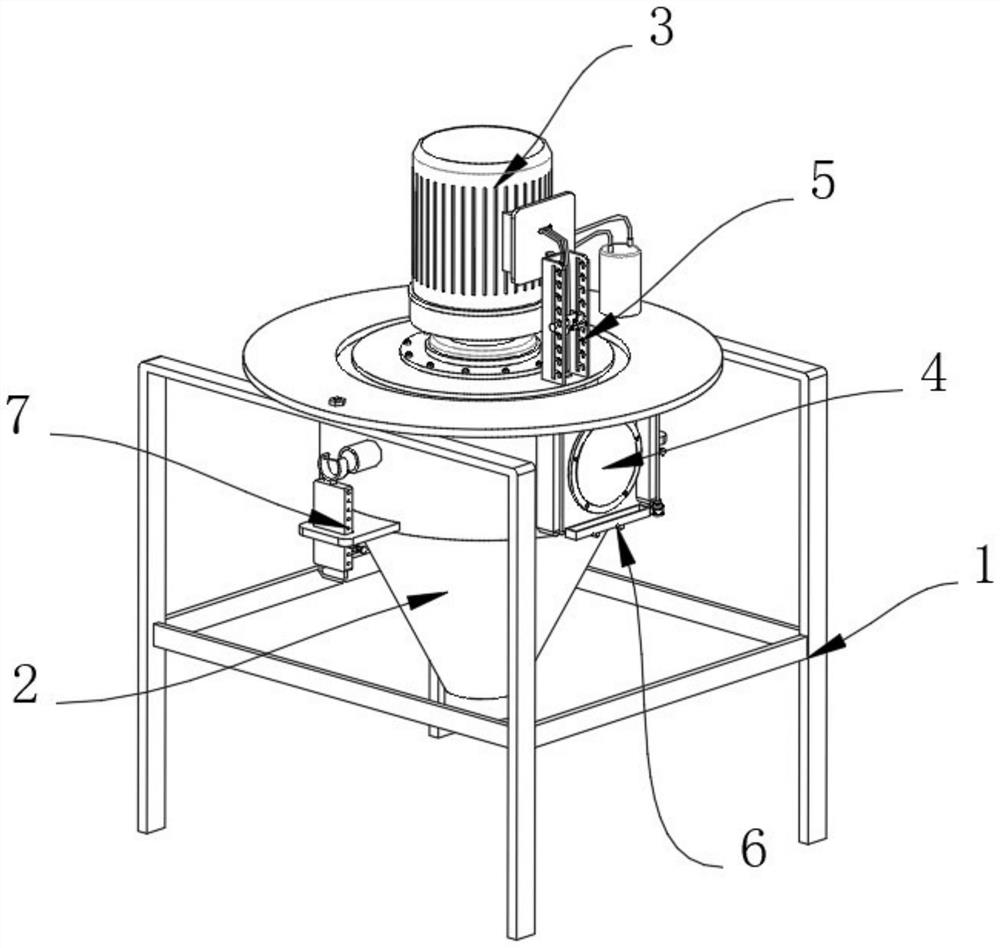

[0048] Example 1, as Figure 1-8 As shown, the present invention provides a rotary atomizer applied to the drying of new energy electrode materials, including a bracket 1 and a lead structure 5, a barrel 2 is installed on the surface of the bracket 1, and an atomizer is installed inside the barrel 2, The circular arc surface of the barrel 2 is provided with an observation mirror 4 by means of bolts, the upper end of the barrel 2 is provided with a servo motor 3, the upper end of the barrel 2 is provided with a lead structure 5, and the circular arc surface of the barrel 2 is provided with a cleaning structure 6, The arc surface of the barrel 2 is provided with a support structure 7 .

[0049] The specific settings and functions of the lead structure 5 , the cleaning structure 6 and the support structure 7 will be described in detail below.

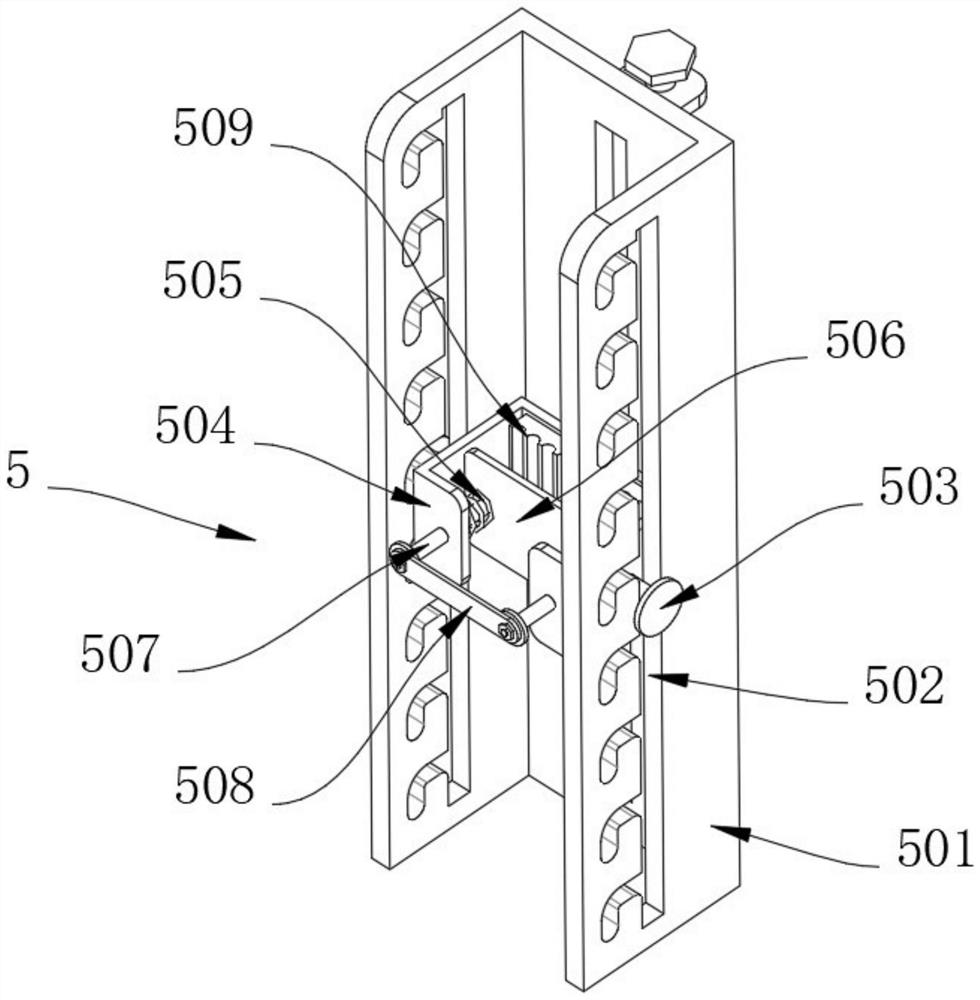

[0050] like image 3 and Figure 4 as well as Figure 9 and Figure 10 As shown, the lead structure 5 includes an extension frame 50...

Embodiment 2

[0057] Embodiment 2, on the basis of Embodiment 1, the support structure 7 includes a welding plate 71, the welding plate 71 is fixedly connected to the arc surface of the barrel 2, and a support plate 72 is slidably inserted in the welding plate 71. The support plate 72 A handle 78 is fixedly connected to the lower end of the support plate 72, a bracket 76 is fixedly connected to the upper end of the support plate 72, an elastic rope 77 is fixedly connected to the inner side of the bracket 76, a number of card holes 75 are evenly opened on one side of the support plate 72, and the welding plate 71 A connecting block 73 is fixedly connected to the lower surface of the connecting block 73, and a plug 74 is slidably inserted in the connecting block 73. The size of the plug 74 is adapted to the size of the card hole 75 of the support plate 72, so that the feeding pipe and the water inlet pipe are connected to the When the barrel 2 is on, the feeding pipe or the water inlet pipe ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com