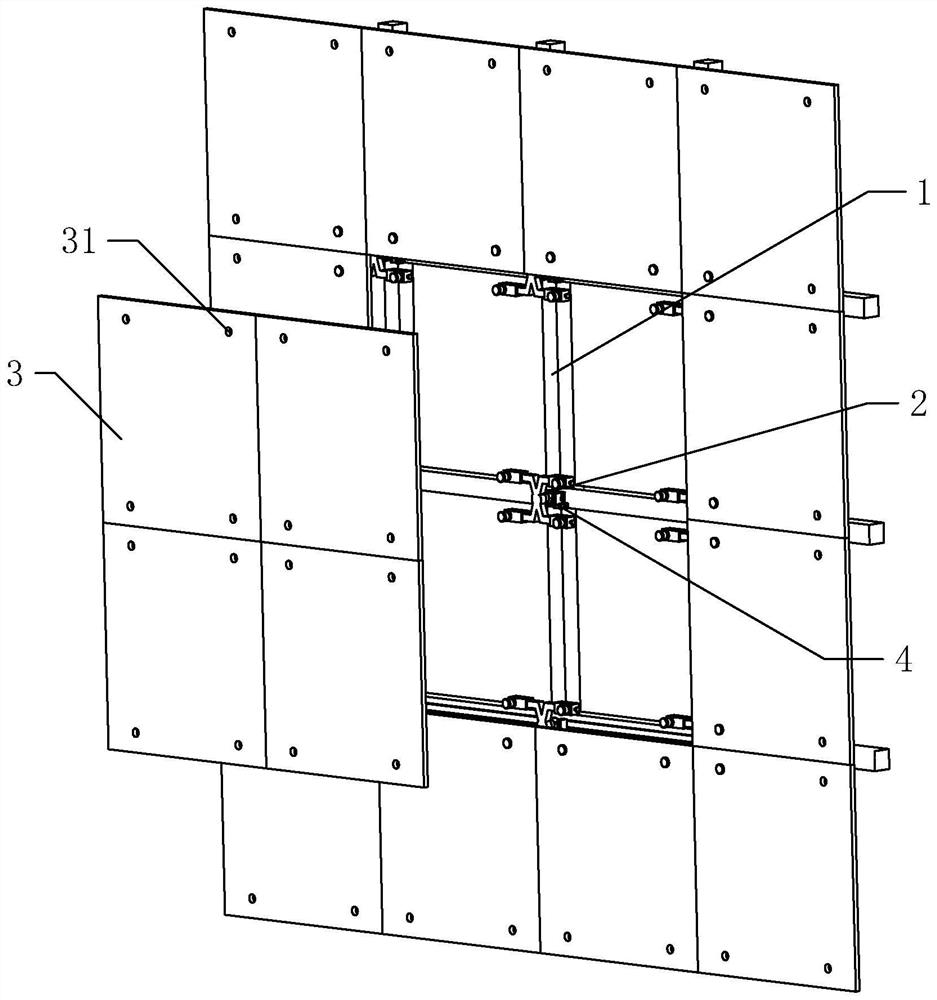

A building glass curtain wall installation structure and its construction method

A technology for architectural glass and installation structure, applied in building components, building structures, buildings, etc., can solve the problems of inability to install, large distance between curtain wall glass panels, and inability to install curtain wall glass panels, and achieve the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0049] A construction method for the installation structure of a building glass curtain wall disclosed by the present invention comprises the following steps:

[0050] Step 1: first install the installation keel 1 on the building wall through bolts;

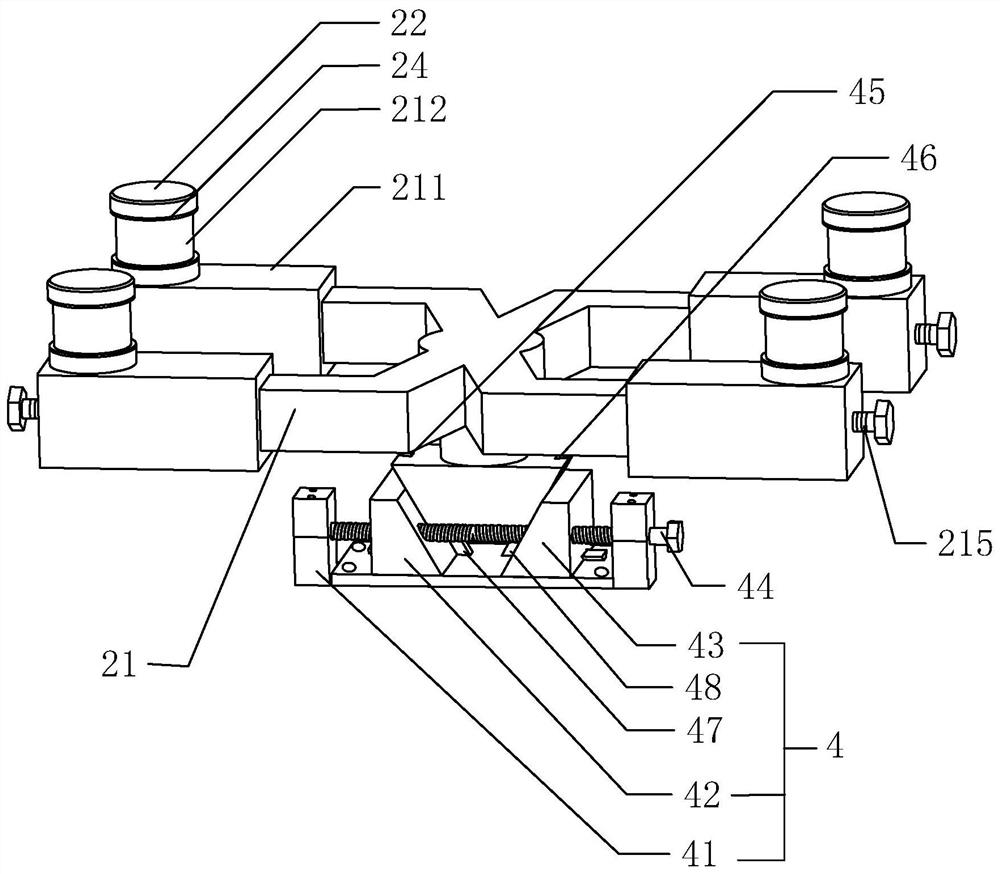

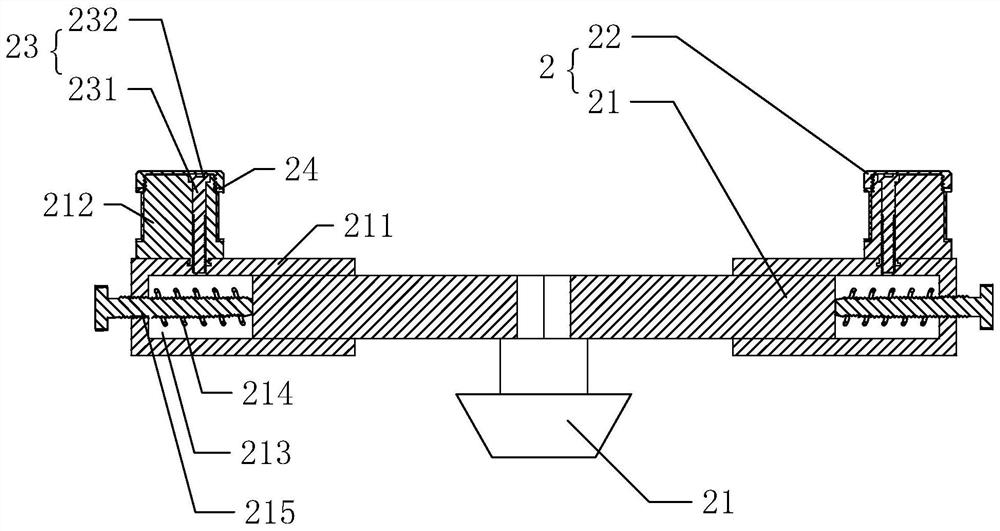

[0051] Step 2: Connect the first wedge block 42 and the second wedge block 43 with the rotating rod 44 and install them on the mounting part 2, slide the first wedge block 42 and the second wedge block 43 on the mounting plate with slide rails, and fix the Block 41 is divided into two halves, first one half is fixed on the installation keel 1 by bolts, and then the installation plate is fixedly connected to the installation keel 1 by bolts, so that the rotating rod 44 is offset against the embedded groove on the surface of the half block, so that It cannot move along its own axial direction, and then the other half is fixed on the previous half with bolts, and the two halves fit together to form a fixed block 41 that is rotationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com