Construction method of concrete spreader supporting structure on hollow floor

A construction method and support structure technology, which is applied in the processing of building materials, building structure, construction, etc., can solve problems affecting construction progress and construction quality, fixed devices cannot be installed normally, and increase construction costs. The effect of reducing the amount of secondary concrete pouring, reducing construction costs, and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

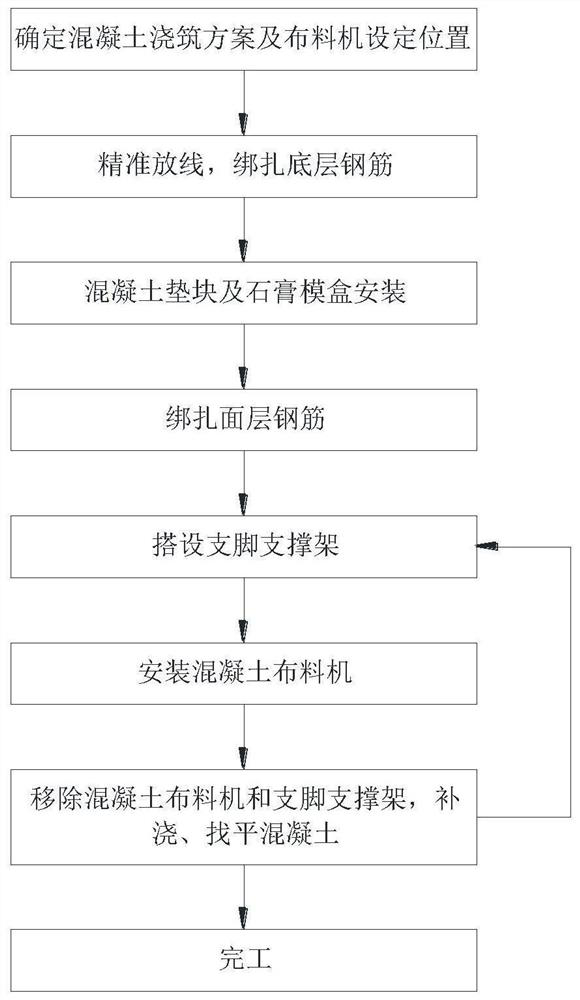

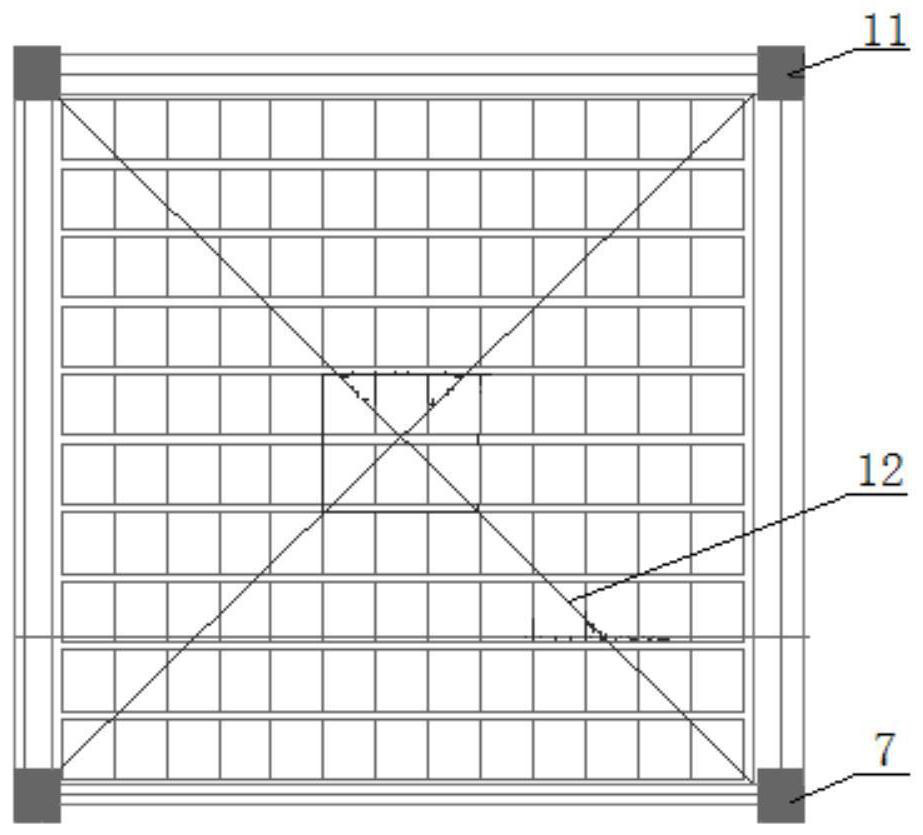

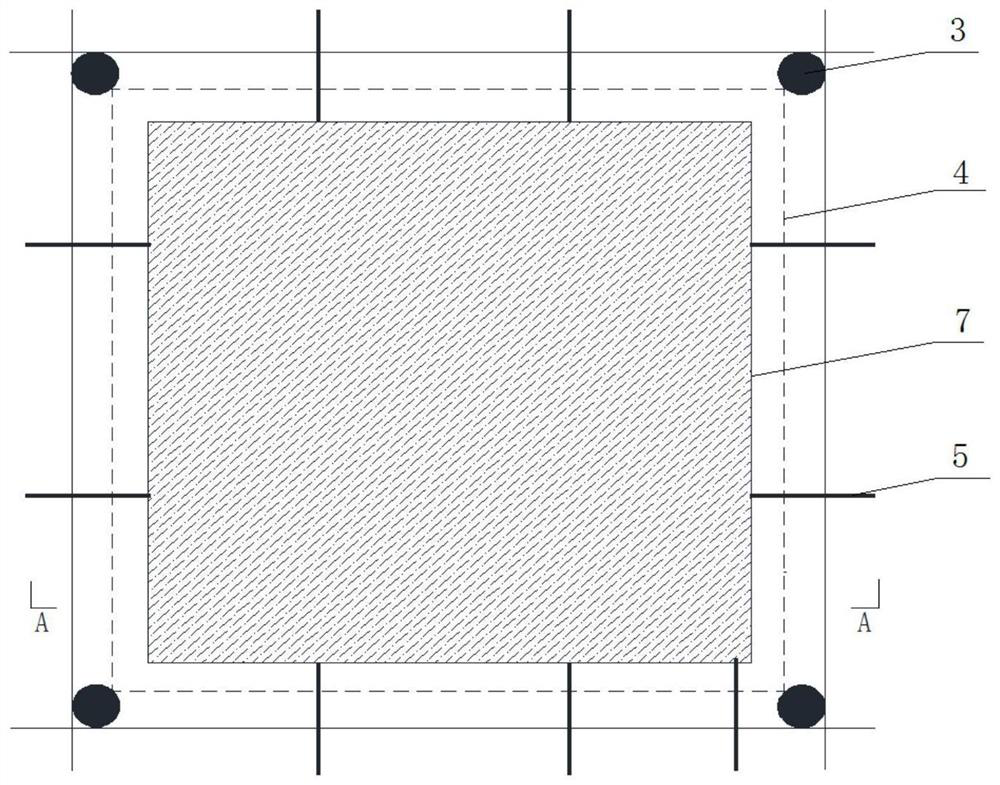

[0037] Such as Figure 1 to Figure 6 Shown, the construction method of concrete distributor support structure on a kind of hollow floor of the present invention, comprises the following steps:

[0038] (1) Determine the concrete pouring plan and determine the setting positions of the concrete placing machine. Due to the limited distribution range of the concrete placing machine, when the area of the hollow floor is large, it is necessary to select multiple installation positions of the concrete placing machine on the bottom formwork 1 of the floor.

[0039] (2) Precisely lay out the wires on the bottom formwork 1 of the floor, and bind the bottom steel bars. Through precise setting out, it is ensured that the steel bars are tied accurately, and the installation accuracy of the concrete pad A2, the concrete pad B10, and the gyps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com