Pre-tensioning lining steel ring reinforcing matching device and method

A pre-tensioning and lining technology, used in measuring devices, shaft equipment, shaft linings, etc., can solve the problems of not being effectively in tension and the overall stress state of the inner lining steel ring is incomplete, so as to achieve a perfect stress system. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

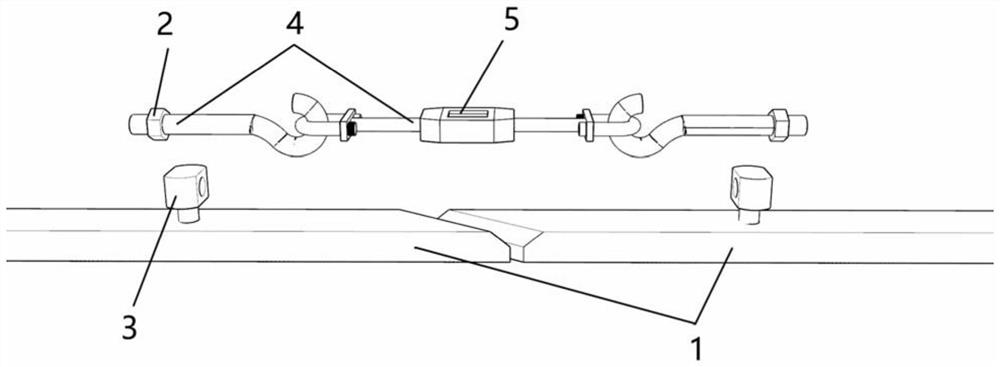

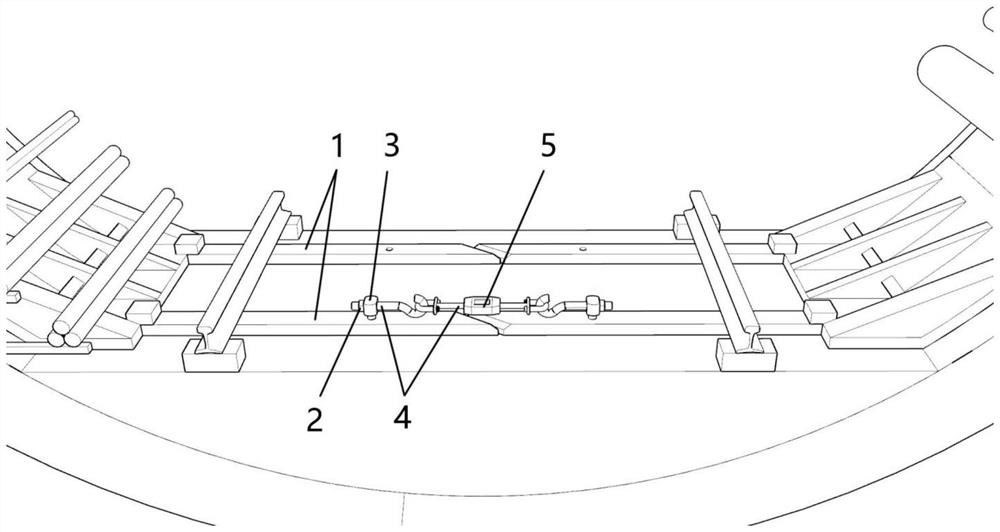

[0023] like figure 1 , 2, the present invention provides a pre-stretched lining steel ring reinforcement supporting device, including steel rod 1, connecting bolts 3, tightening nuts 2, tie rods 4 and 5 tension gauges. A bolt hole with a diameter of 2 cm is reserved on each steel tie bar 1, and the screw rod of the connecting bolt 3 can be fixed in the bolt hole of the steel tie bar 1; 4. Install the tension gauge 5 in the middle, and install the tightening nut 2 at the rear end of the straw 4. After the installation is completed, the tightening nut 2 is continuously tightened, and the pre-tension force is judged by the tension gauge 5. When the design value is reached, the tightening is stopped, and the welding is carried out through the reserved groove on the steel tie bar 1.

[0024] The using method of the embodiment of the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com