Base for drawer belt conveyor

A belt conveyor and drawer-type technology, which is applied in the direction of conveyor objects, transportation and packaging, and support frames, can solve the problems of inconvenient maintenance, inability to adapt to mobile conveyor installation, and poor practical performance of telescopic belt conveyors. Simple, good practical performance, and the effect of improving practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

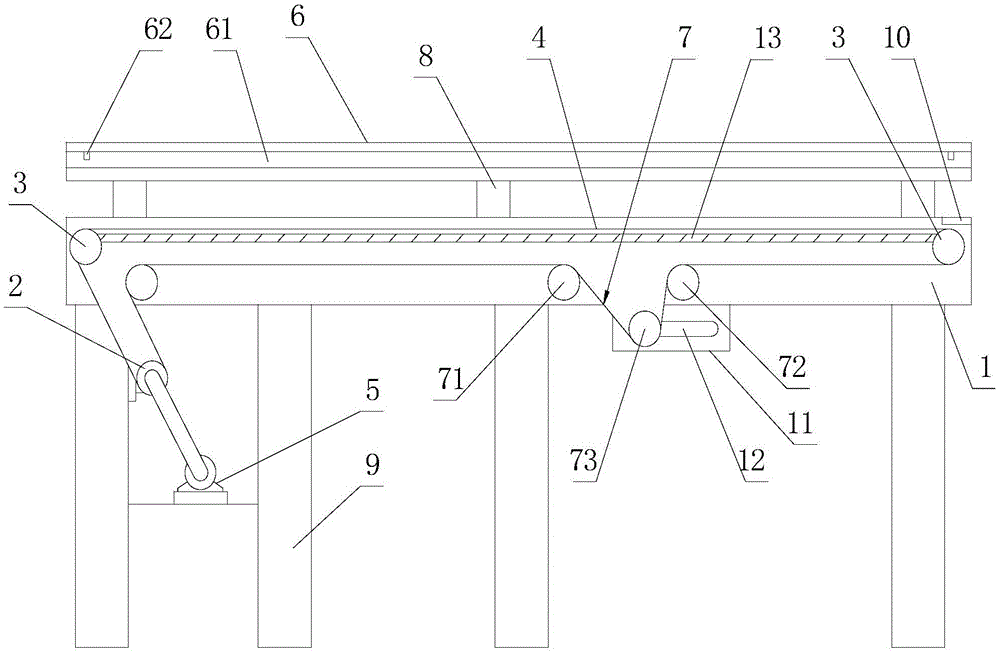

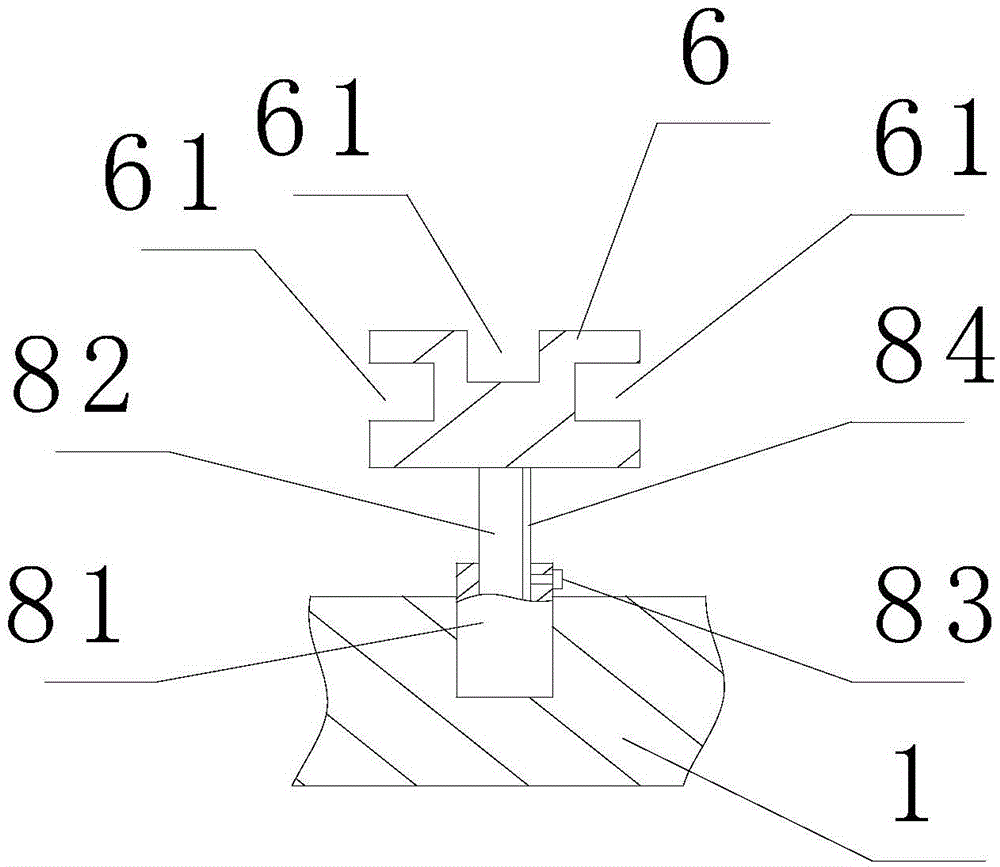

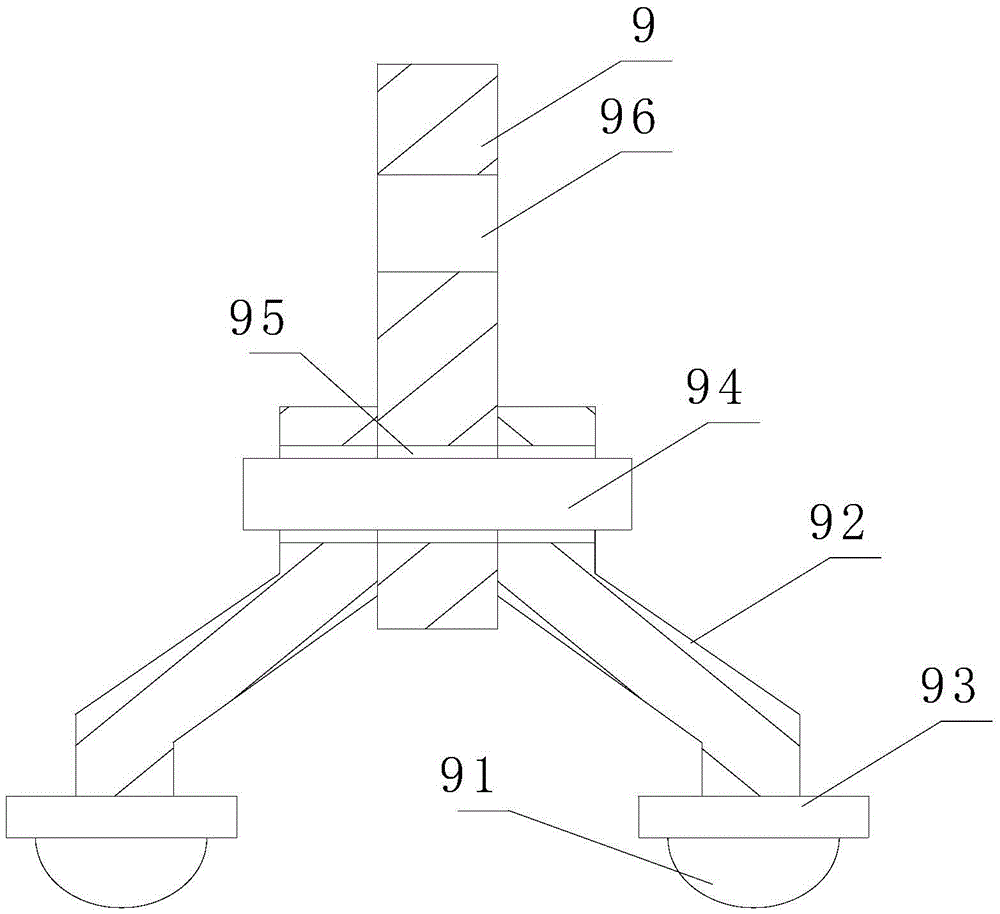

[0013] Such as figure 1 , figure 2 , image 3 As shown, the base for a drawer type belt conveyor includes a frame 1, a driving roller 2 rotatably connected to the frame 1, at least two driven rollers 3 rotatably connected to the frame 1, and sleeved on the driving roller 2. The conveyor belt 4 on the roller 2 and the driven roller 3, the driving motor 5 connected with the driving roller 2, the frame 1 is provided with two height-adjustable installation rods, the two installation rods There is a chute on the side wall, each of the chute 61 is provided with a limit pin 62 to control the effective displacement of the chute, and the middle part of the frame 1 is provided with an adjustment device for adjusting the tension of the conveyor belt 4. device 7, the adjustment device 7 includes a first roller 71 and a second roller 72 fixedly connected to the frame 1 respectively, and an adjustable wheel arranged between the first roller 71 and the second roller 72 on the frame 1 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com