High-efficiency low-energy-consumption clear water self-priming pump

A self-priming pump, low energy consumption technology, applied to the components, pumps, drive pumps, etc. of the pumping device for elastic fluid, can solve the problems of small contact area and low pumping efficiency, and achieve increased contact area and improved safety. resistance, overcoming the effect of small contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

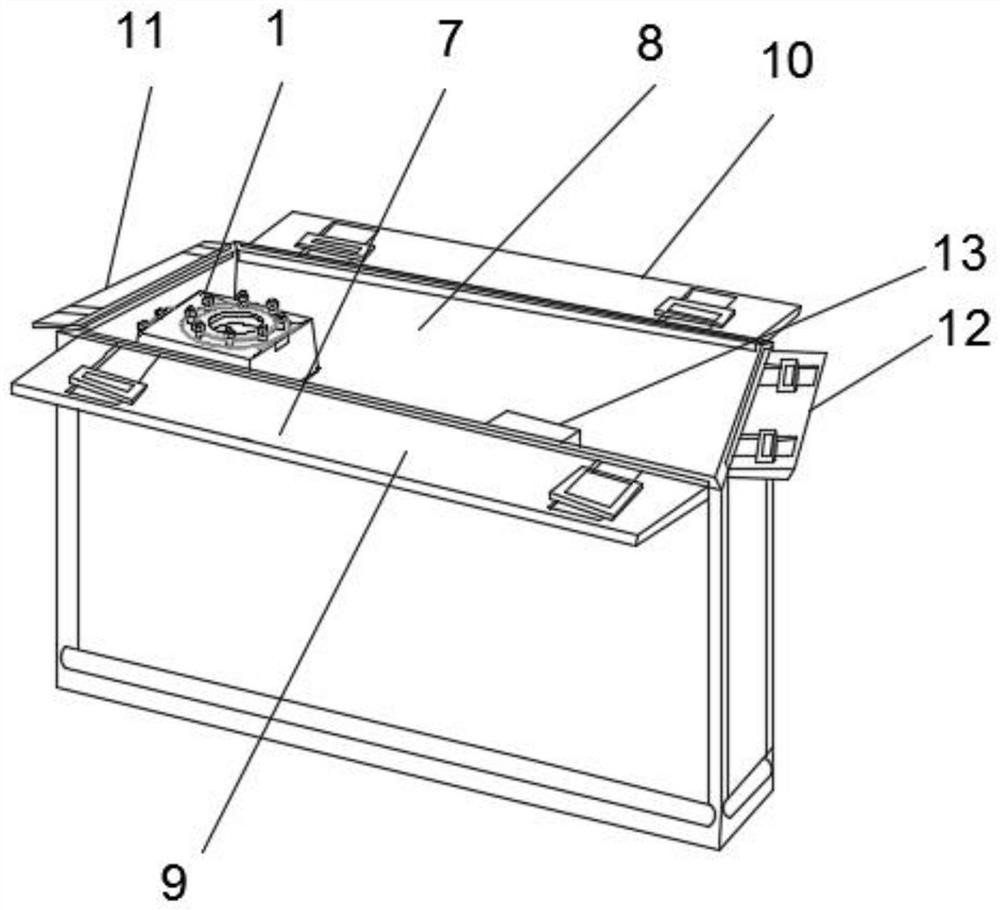

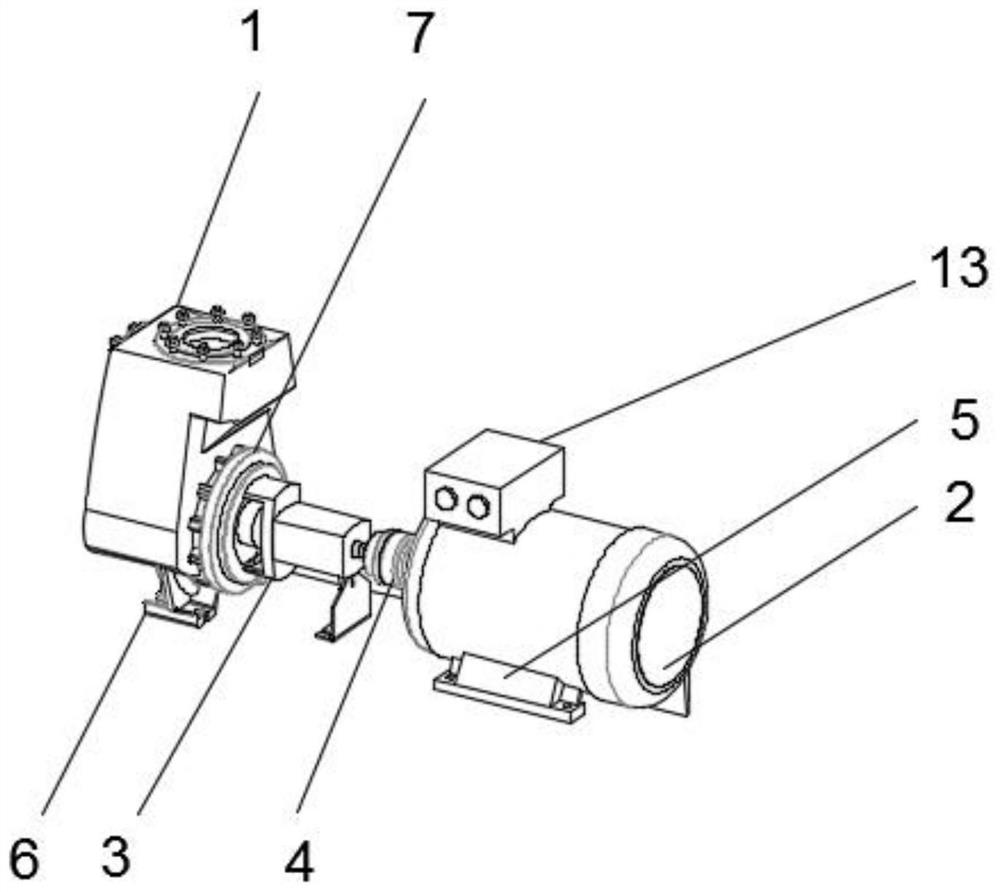

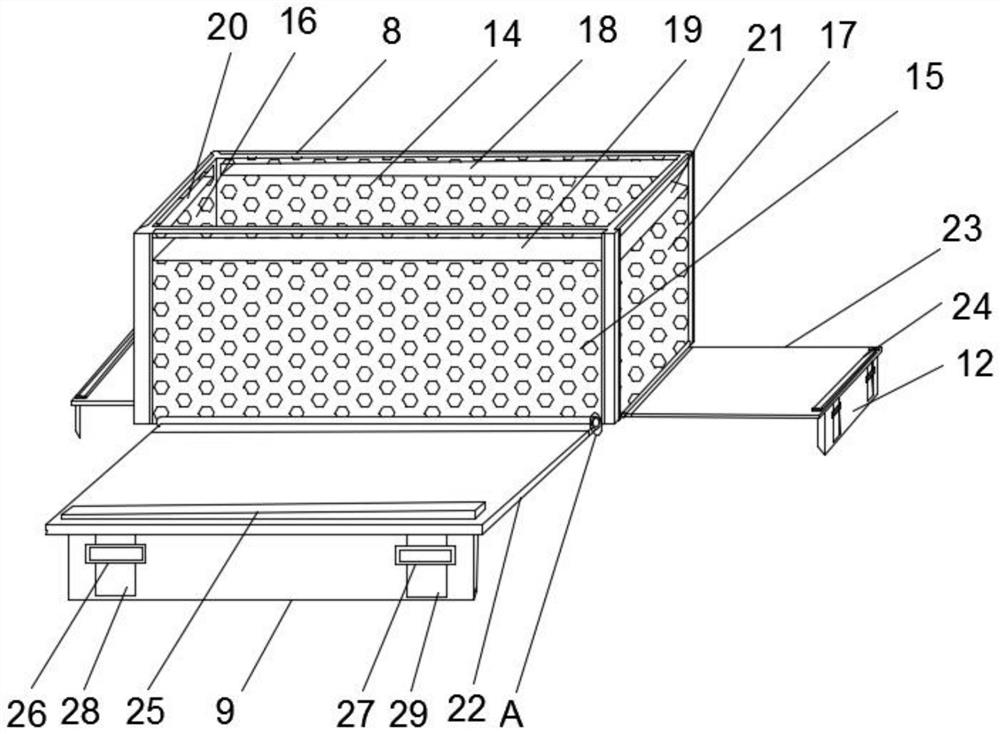

[0035] like Figure 1-6 As shown, a clean water self-priming pump with high efficiency and low energy consumption comprises a self-priming pump body 1 and a storage box 8, the self-priming pump body 1 is located inside the storage box 8, and the self-priming pump body 1 A motor 2 is fixedly connected to one side, and a bearing body 3, a shaft column 4 and a sealing flange 7 are fixedly connected between the self-priming pump body 1 and the motor 2, and the bearing body 3 is located between the sealing flange 7 and the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com