Apparatus and method for regulating and controlling trailing edge flow of v-shaped flame holder by using surface arc plasma excitation

A flame stabilizer and plasma technology, applied in the aviation field, can solve problems such as complex mechanical devices and large total pressure loss, and achieve the effect of reducing the flow separation area and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

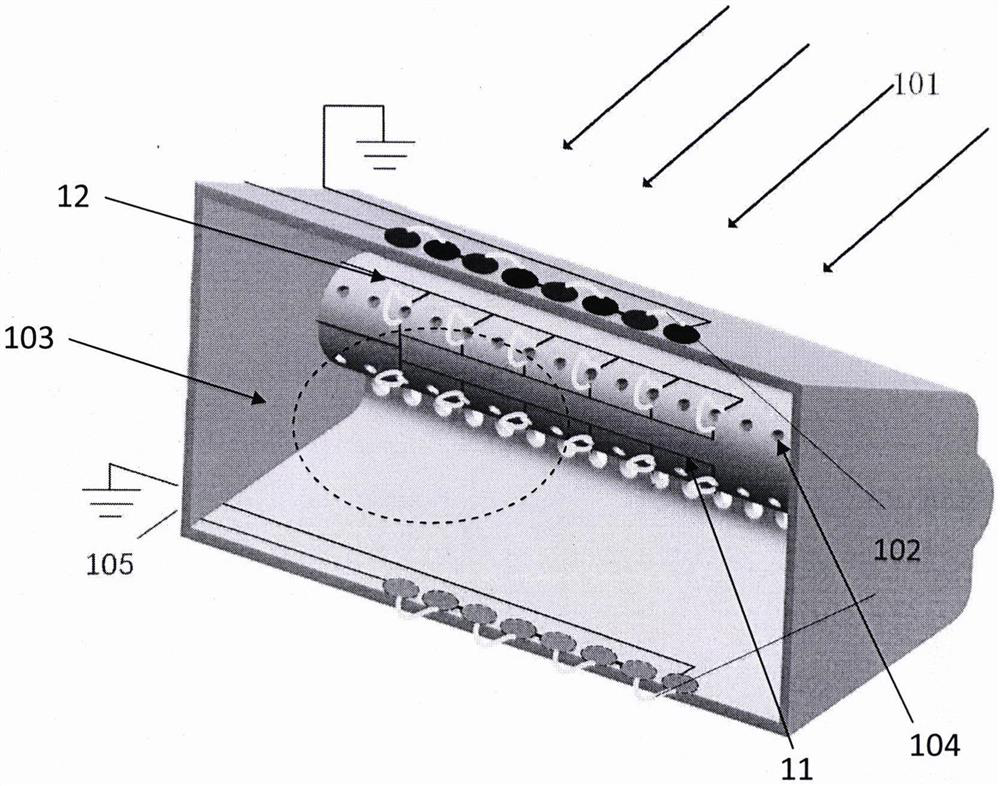

[0033] now attached figure 1 The method of the present invention is further described. The invention provides a device for regulating and controlling the flow at the trailing edge of a V-shaped flame stabilizer by using surface arc plasma excitation.

[0034] The v-shaped flame stabilizer is in the shape of a groove, and the four walls of the groove include the upper wall, the lower wall, and the left and right walls. The lower wall is placed horizontally, and there is an angle between the upper wall and the lower wall. The V-shape of the part, so it is called "v-shaped" flame stabilizer, and the internal cavity of "v-shaped" flame stabilizer is "v-shaped cavity". The left and right walls respectively clamp the upper and lower walls from the left and right sides, and are fixedly connected with both, and the left and right walls are usually placed parallel to each other. like figure 1 As shown, behind the upper and lower walls, there is a rear wall between the upper wall and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com