Heating, shaping, cutting and edge sealing device for papermaking mesh

A heating setting and edge banding device technology, which is applied in textiles and papermaking, fabric edge trimming, fabric surface trimming, etc., can solve the problems of inconsistent elongation and shrinkage of papermaking nets, and low shaping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

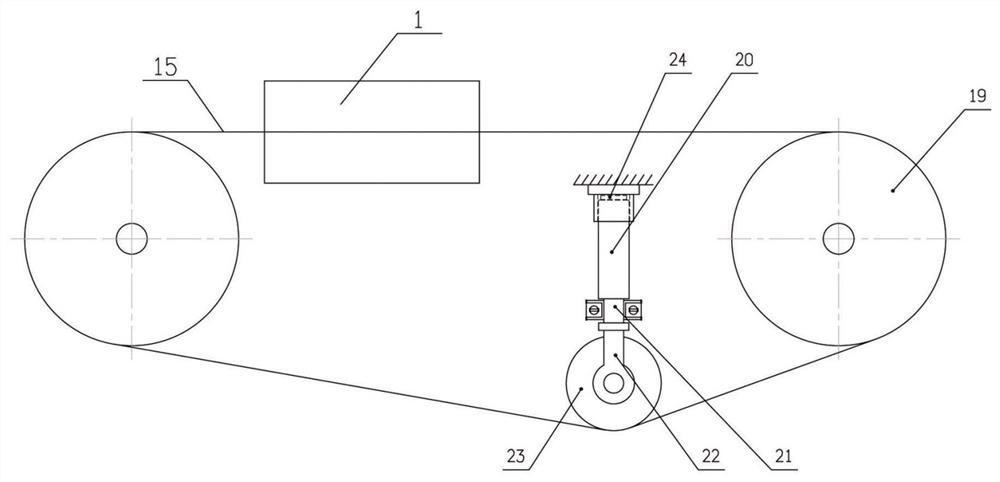

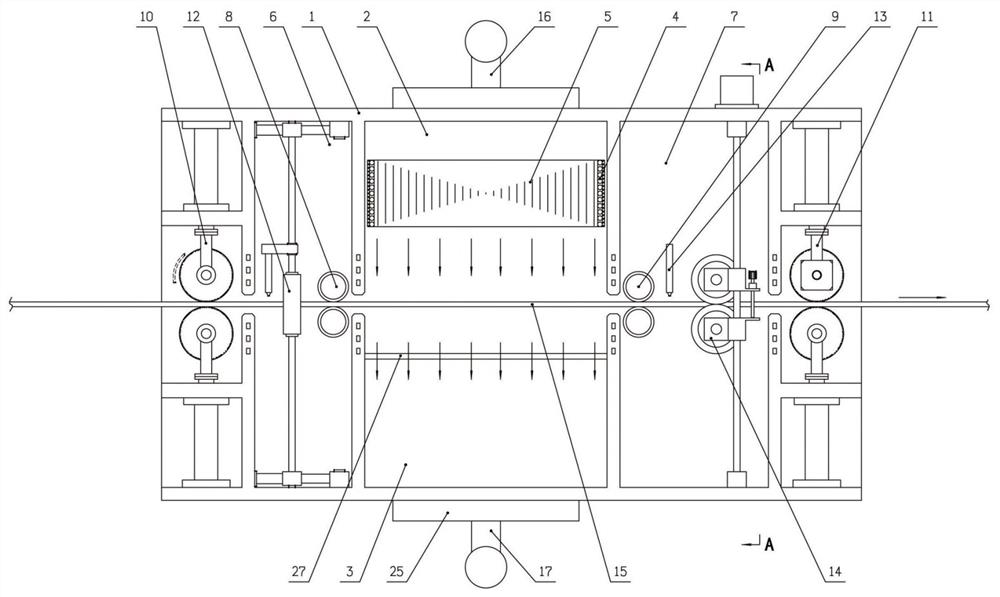

[0037] Embodiment 1: as figure 1 As shown, the sizing machine not only includes two parallel cylinders 19, but also includes a tensioning wheel group, aligning and sewing the two ends of the papermaking net to be sizing along the warp direction into a ring shape, and then set it on the two parallel drums of the sizing machine. On the pulley and the tension pulley, make it rotate with the pulley at a constant speed. The paper-making wire heating and setting device is used to heat the single-belt area of the endless paper-making wire, so that the paper-making wire continuously passes through the heating and setting device area of the setting machine, so as to ensure that the paper-making network can be fully and evenly heated and shaped in the heating and setting device area.

[0038] Among them, the tension wheel set used is as follows: figure 1 As shown, a mounting seat is provided on the calibrating frame and a tension mechanism electric push rod 20 is set in the mountin...

Embodiment 2

[0046] Embodiment 2: On the basis of Embodiment 1, a deviation correction device 12 is installed in the front detection chamber 6 , and a laser leveling probe 13 and a shearing device 14 are installed in the rear detection chamber 7 . Among them, the laser leveling probe 13 transmits the signal to the controller, and the controller starts the shearing device 14 to work according to the feedback of the laser leveling probe 13. Usually, the shearing device 14 does not work directly to prevent it from shaping the papermaking process. cause disturbance. The deviation correcting device 12 provides a leveling basis for the laser leveling probe 13, otherwise the laser leveling probe 13 on one side may fail to detect due to the overall deflection of the papermaking network, and blindly shear and damage the papermaking network.

[0047] The mode of deviation correction device 12 can adopt the device of any existing deviation correction function, or adopt such as Figure 4 A form is sh...

Embodiment 3

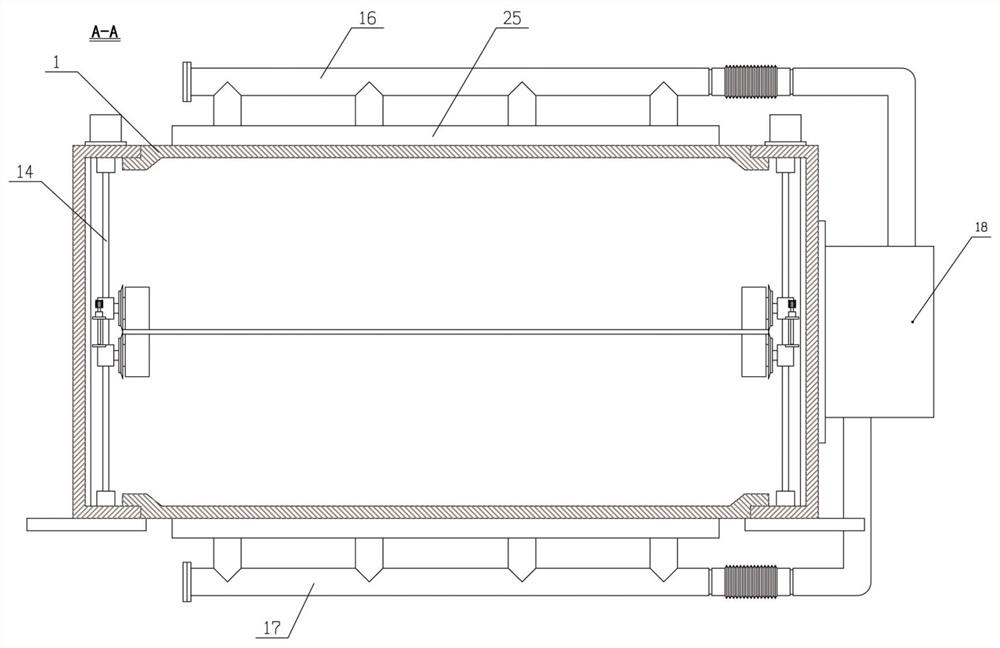

[0048] Embodiment 3: On the basis of Embodiment 2, the driving mechanism wherein is as Figure 5 and Figure 6 As shown, the racks 1246 are respectively installed on the upper and lower ends of the vertical bar on one side, and the racks 1246 are installed on the upper and lower ends of the vertical bar on the other side. A pair of racks on the upper and lower sides are interlocked and have matching gaps, and a pair on the upper and lower sides. The racks are respectively restrained by the guide seat 1247 and can only slide laterally. A gear 1245 is provided in each matching set in the matching gap between the upper and lower racks, and the gear 1245 meshes with its upper and lower adjacent racks. A worm gear 1243 mounted on the gear shaft 1244 meshes with the worm 1242, the worm is connected with the shaft of the traverse motor, and the worm gear and the motor are installed in the support 1241 respectively. Thus, the controller according to Figure 4 The detection signal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com