Field operation optical cable splice closure and using method thereof

A field optical cable and splice box technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of high use cost, low splice efficiency, inconvenient operation, etc., and achieve the effect of reduced splice cost, simple structure and convenient splice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

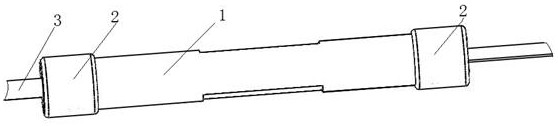

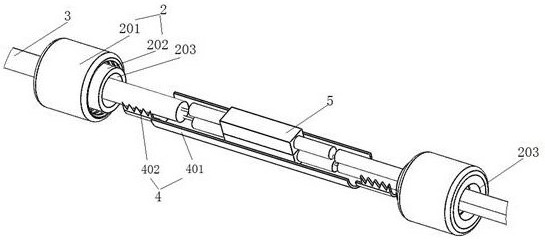

[0051] This embodiment includes a housing 1 and a fixing fixture 4. Both ends of the housing 1 are connected with terminals 2. After the optical cable 3 is connected, the fixing fixture 4 is clamped at the joint of the optical cable 3, and the joint of the optical cable 3 is sealed in the housing. In body 1.

[0052] Further optimization, after the terminal 2 is connected to the housing 1, the housing 1 and the terminal 2 form a cavity, and the cavity is filled with sealing glue.

[0053] Further optimization, the fixing fixture 4 includes a connecting part 401, and the clamping part at both ends of the connecting part 401 is a serrated connecting part 402, the serrated connecting part 402 can clamp the optical cable 3, and the serrated connecting part 402 can be embedded in the sheath of the optical cable 3 .

[0054] Among them, in order to better ensure that the connection of the optical cable 3 has better tensile properties, a protrusion is provided on the side facing the...

Embodiment 2

[0064] This embodiment is basically the same as Embodiment 1, the difference is that: the housing 1 is cylindrical, the diameter of the housing 1 is 14 mm, and the length is 105 mm.

Embodiment 3

[0066] This embodiment is basically the same as Embodiment 1, the difference is that: the housing 1 is cylindrical, the diameter of the housing 1 is 16 mm, and the length is 110 mm.

[0067] In actual use, the specific usage method of the field optical cable splice box is as follows:

[0068] S1: Pass one of the optical cables 3 through the wire hole 203 on one of the ends 2, and make the sheath of the optical cable 3 and the wire hole 203 on the elastic member 202 in the end 2 achieve an interference fit;

[0069] S2: Pass another optical cable 3 through the wire hole 203 on the other end 2, and make the sheath of the optical cable 3 and the wire hole 203 on the elastic member 202 in the end 2 achieve an interference fit;

[0070] S3: passing the optical cable 3 described in S1 or S2 through the housing 1, so that the housing 1 is placed on the optical cable 3;

[0071] S4: After connecting two optical cables 3, place the joint of the optical cable 3 in the connection part 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com