Method for accurately detecting fault information of IT equipment in machine room

A technology for equipment failure and detection methods, applied in computer parts, instruments, characters and pattern recognition, etc., can solve the problems of lack of risk warning, poor flexibility, less inspection, missed inspection or false inspection, etc., to improve the efficiency of inspection , the effect of reducing risks and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following are only exemplary and do not limit the protection scope of the present invention.

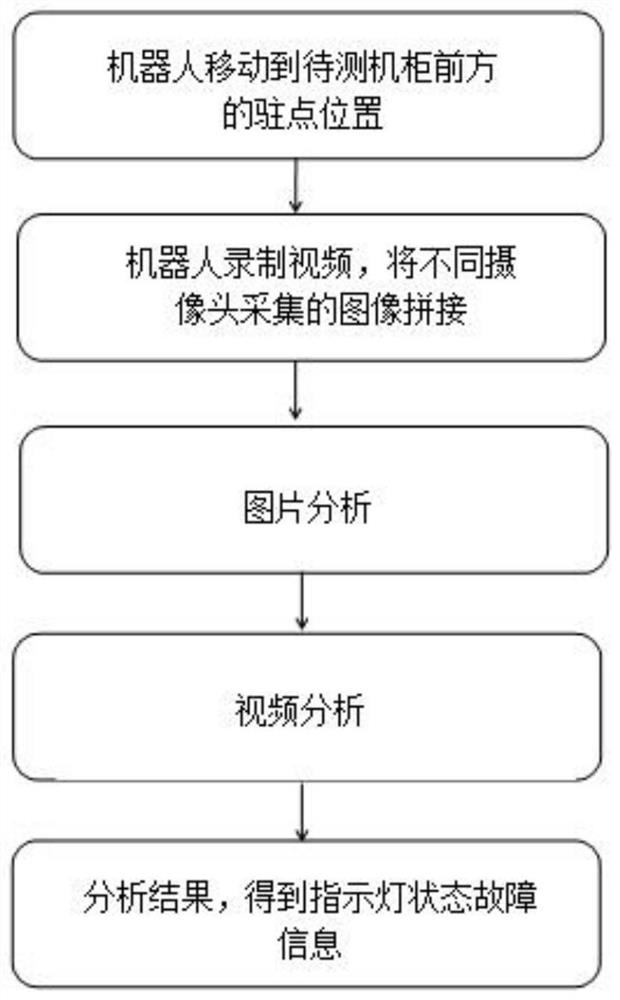

[0056] Such as figure 2 As shown, the method for accurately detecting fault information of IT equipment in a computer room according to this embodiment includes the following:

[0057] S1. The robot moves to the calibrated stagnation position in front of the cabinet to be tested.

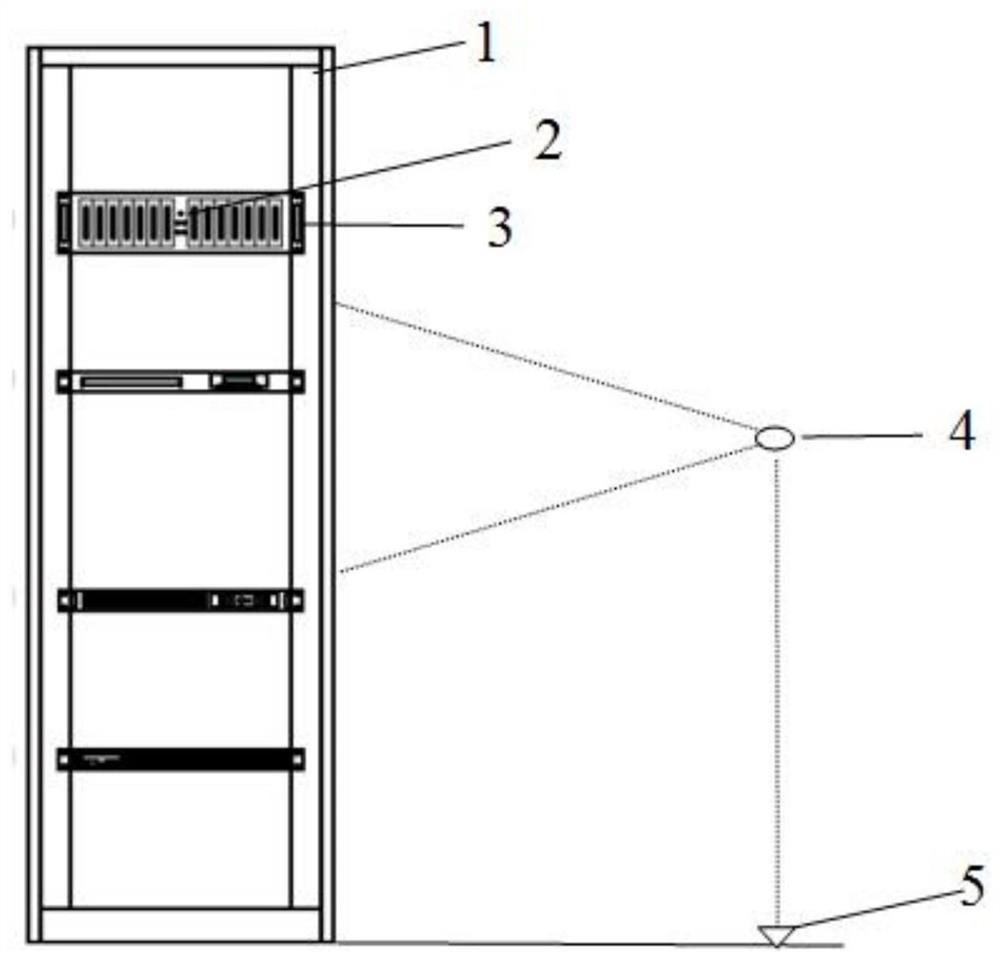

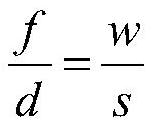

[0058] In this embodiment, as figure 1 As shown, 1 indicates the cabinet to be tested, 2 indicates the indicator light, 3 indicates the IT equipment, 4 indicates the camera on the robot, 5 indicates the stagnation position, and at least one row of cameras is installed on the robot ( figure 1 Only one is identified). There are several cameras in each column at equal intervals fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com