Spacing-adjustable double-shaft cutting knife set

A cutting knife, adjustable technology, applied in the direction of metal processing, etc., can solve the problems of not cutting dishes, not being able to cut dishes of different thicknesses, and not being able to adjust the distance between blades, etc., to achieve the effect of easy cleaning, concise structure, and simple shape of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

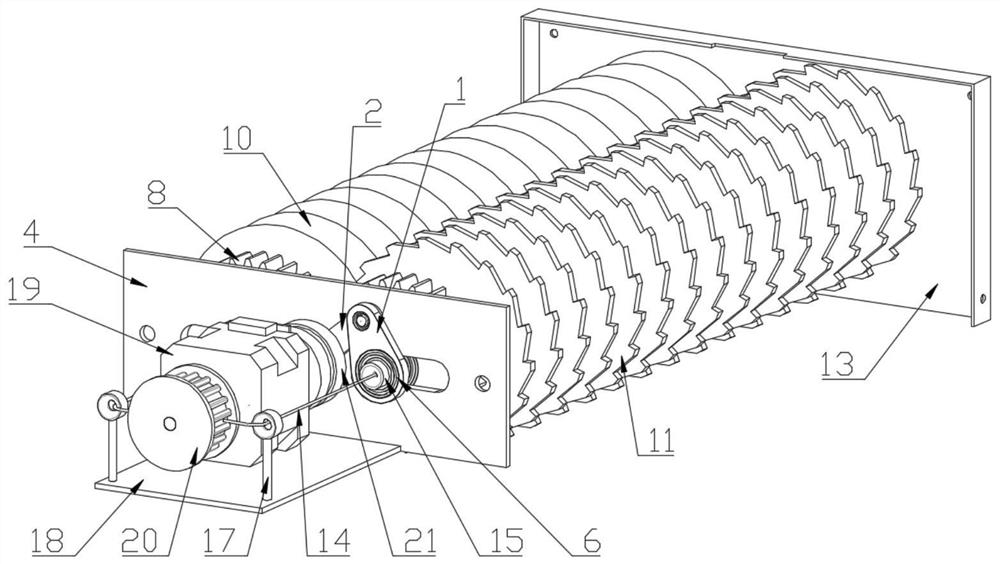

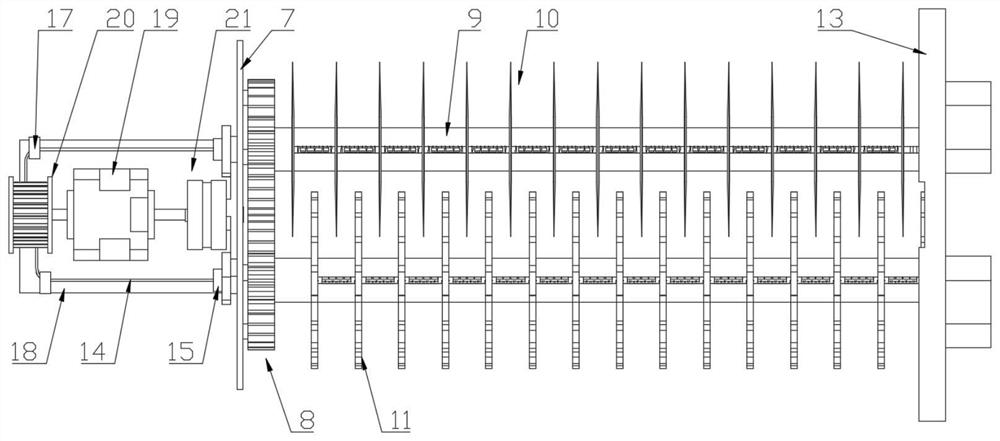

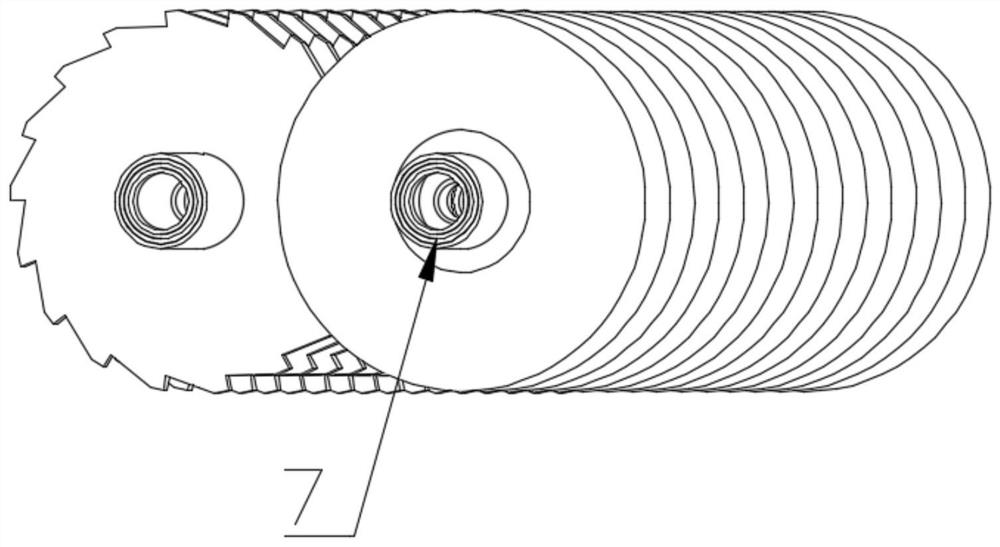

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] refer to Figure 1 to Figure 10 , a dual-axis cutting knife group with adjustable spacing, comprising a linkage mechanism, a knife set mechanism and an adjustment mechanism, the linkage mechanism comprising a linkage arm (1), a linkage arm (2), a linkage arm Connecting bearing (3), connecting rod positioning frame (4), main shaft connecting arm bushing (5) and connecting rod arm bearing (6), the knife group mechanism includes main shaft bearing (7), main shaft gear (8), Hollow slotted main shaft (9), circular blade (10), multi-jaw blade (11), spring (12) and support shell (13); described adjustment mechanism comprises pull wire (14), guide coil (15), stop Push bearing (16), thread passing rubber ring (17), threading coil support plate (18), double-head stepper motor (19), reel (20) and electromagnetic clutch (21).

[0023] The two ends of the connecting rod ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com