Novel sterile thick sauce and particle filling device and method

A filling device and thick sauce technology, which is applied in the field of new aseptic thick sauce and granule filling devices, can solve problems such as automatic cleaning and filling, realize cleaning automation, realize aseptic filling, and reduce labor effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

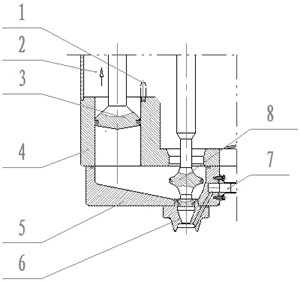

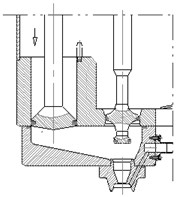

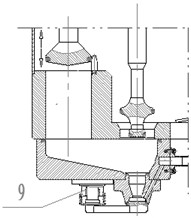

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] The invention provides a novel aseptic thick sauce and granule filling device, the structure of which is as follows: Figure 1 to Figure 3 As shown, it includes a material cylinder 2, a plunger barrel 4, a large flow filling channel 5 and a feeding nozzle 6 connected in sequence, wherein a plunger 3 is arranged in the plunger barrel 4, and the plunger 3 controls the material in the material cylinder 2. The material is pressed into the feeding nozzle 6 through the large flow filling channel 5; the feeding nozzle is provided with a filling valve core 8 and a return pipeline 7, the upper part of the filling valve core 8 is connected with the material cylinder 2, and the lower part is connected with the Feeding mouth 6 links to each other.

[0023] As a further improvement, a dummy cup mechanism 9 is provided outside the feeding nozzle.

[0024] As a further improvemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com