Expressway pile wall type composite roadbed and construction method thereof

A technology for highways and composite roadbeds, applied in infrastructure engineering, roads, roads, etc., can solve the problems of differential settlement of old and new roadbeds, long construction period, deformation of old roadbeds, etc., and achieve fast construction, low cost, and reduced floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

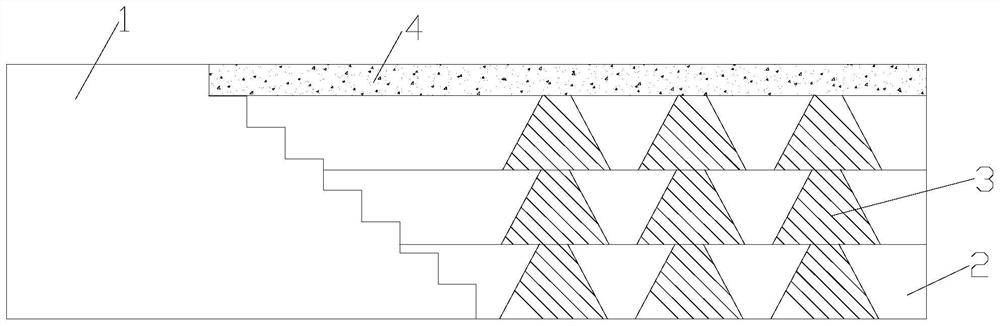

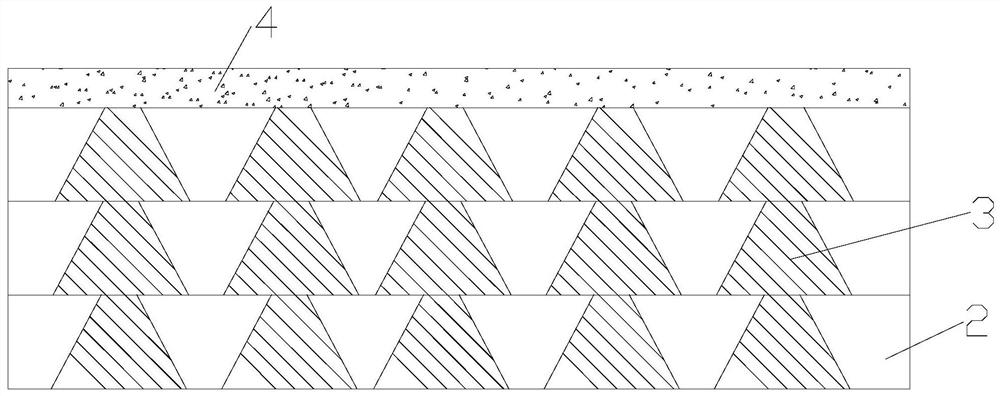

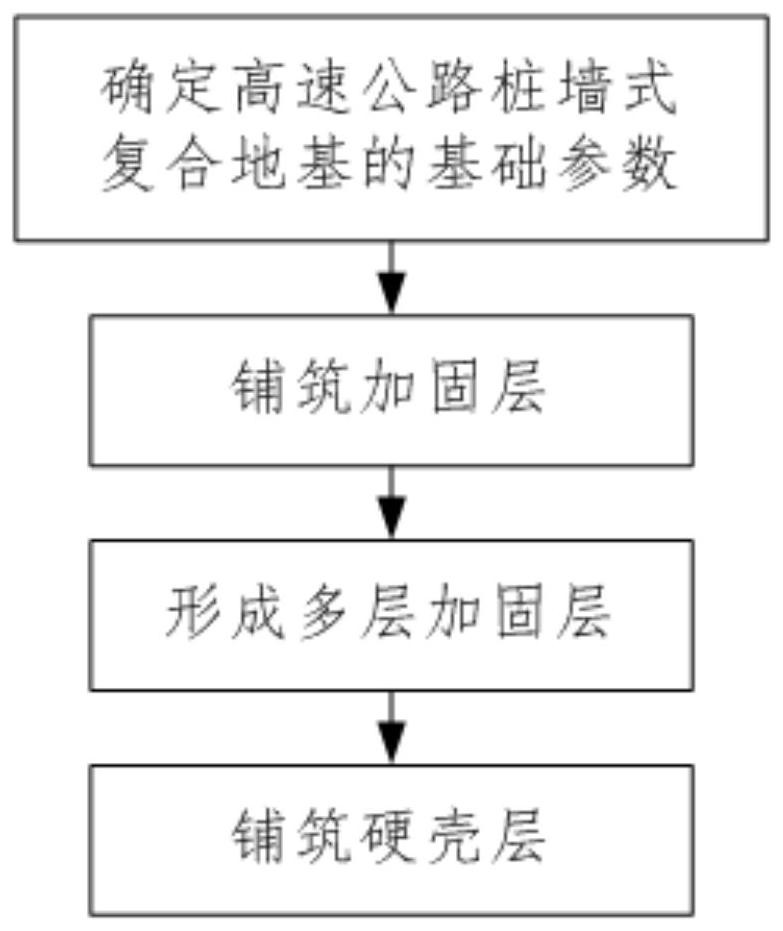

[0034] Such as figure 1 As shown, a highway pile-wall composite subgrade according to the present invention comprises multi-layer reinforcement layers successively paved from bottom to top respectively, and a hard shell layer 4 is paved on the top of the multi-layer reinforcement layer;

[0035] The reinforcement layer includes a mixed soil layer 2 and a plurality of reinforcement soil layers 3 arranged at intervals and constructed in the mixture soil layer 2. The number of reinforcement soil layers 3 in each layer of the reinforcement layer is equal and corresponds to each other. The multi-layer reinforcement layer The corresponding reinforced soil layer 3 forms a plurality of spaced reinforced pile wall structures, and a mixed soil pile wall structure is formed between two adjacent reinforced pile wall structures.

[0036] In this embodiment, the width of the reinforced pile wall structure is greater than the wheel base of the loaded vehicle, and the width of the reinforced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com