Double-hard-shell-layer on-site reinforcing and filling structure and method of subgrade in muddy soft soil area

A technology of silt soft soil and hard shell layer, applied in infrastructure engineering, roads, roads, etc., can solve problems such as lack of earthwork for filling roadbed and dredging and replacement, poor roadbed reinforcement effect, and engineering construction hazards. , to achieve the effect of easy promotion and use, fast construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

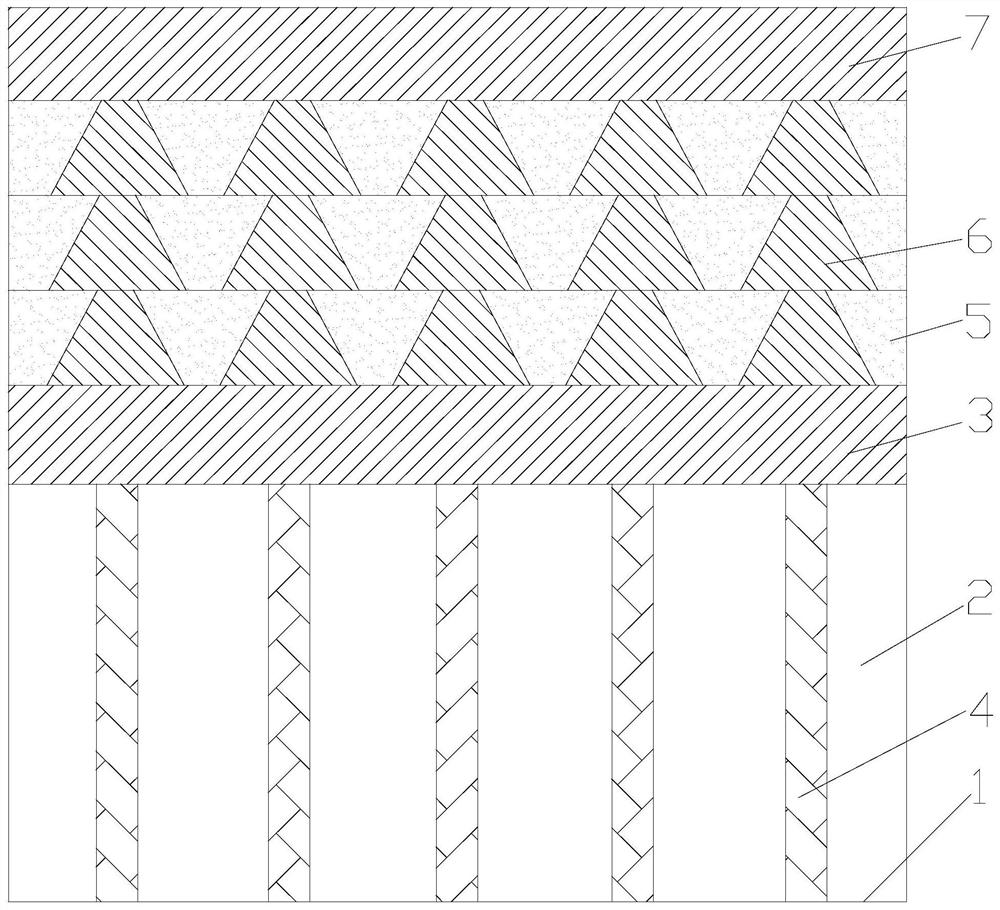

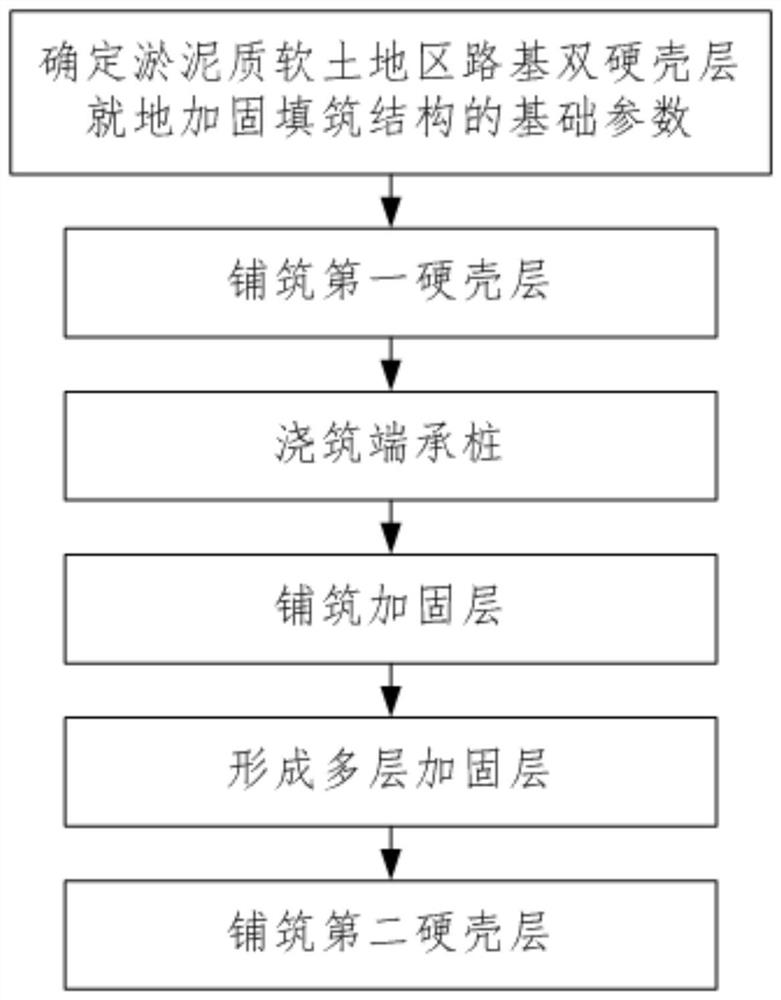

[0032] Such as figure 1 As shown, the in-situ reinforcement and filling structure of the subgrade double hard shell layer in the muddy soft soil area of the present invention includes the first hard shell layer 3 paved on the muddy soft soil layer 2 and a plurality of layers passing through the second hard shell layer respectively. A hard shell layer 3 and a silty soft soil layer 2 are driven to the end-bearing pile 4 on the underlying bedrock 1, and the first hard shell layer 3 is paved with a multi-layer reinforcement layer, and the multi-layer reinforcement layer The top is paved with a second crust layer 7 .

[0033] It should be noted that firstly, the first hard shell layer 3 is paved to provide a working platform for the construction equipment, and then the end-bearing piles 4 are constructed as the load-bearing support foundation, and multi-layer reinforcement layers are paved on the first hard shell layer 3 to form The reinforced pile wall structure and mixed soil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com