Modular beam frame for fabricated house, and storey height variable structure

A modular and prefabricated technology, which is applied in building construction and construction, can solve the problems of low construction efficiency of prefabricated houses, achieve the effects of convenient on-site assembly of houses, saving construction time, increasing storey height and occupying land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

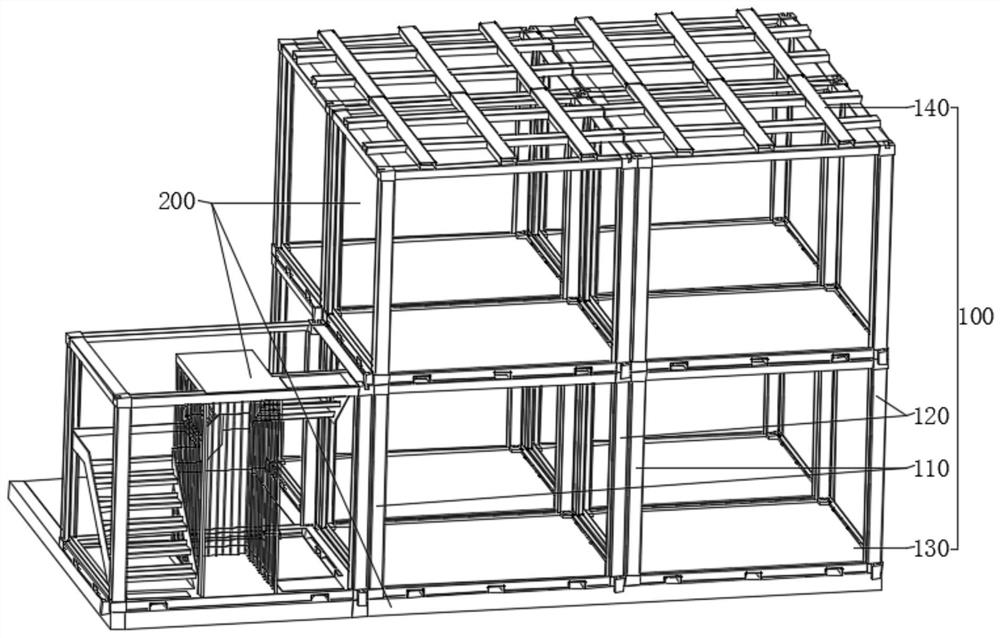

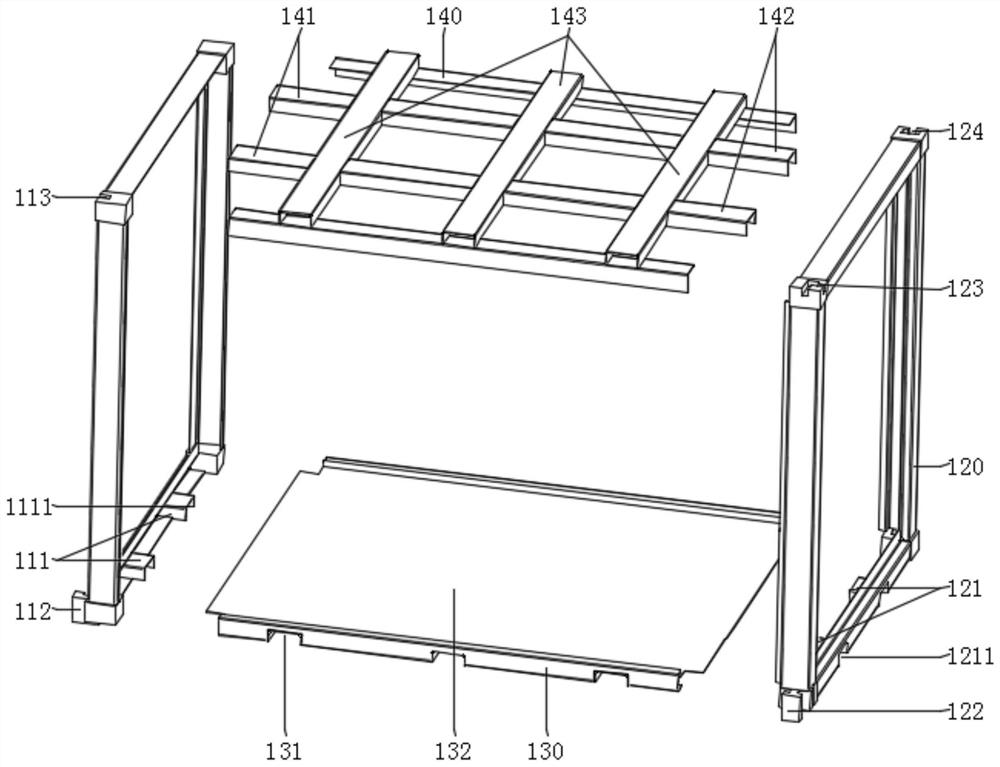

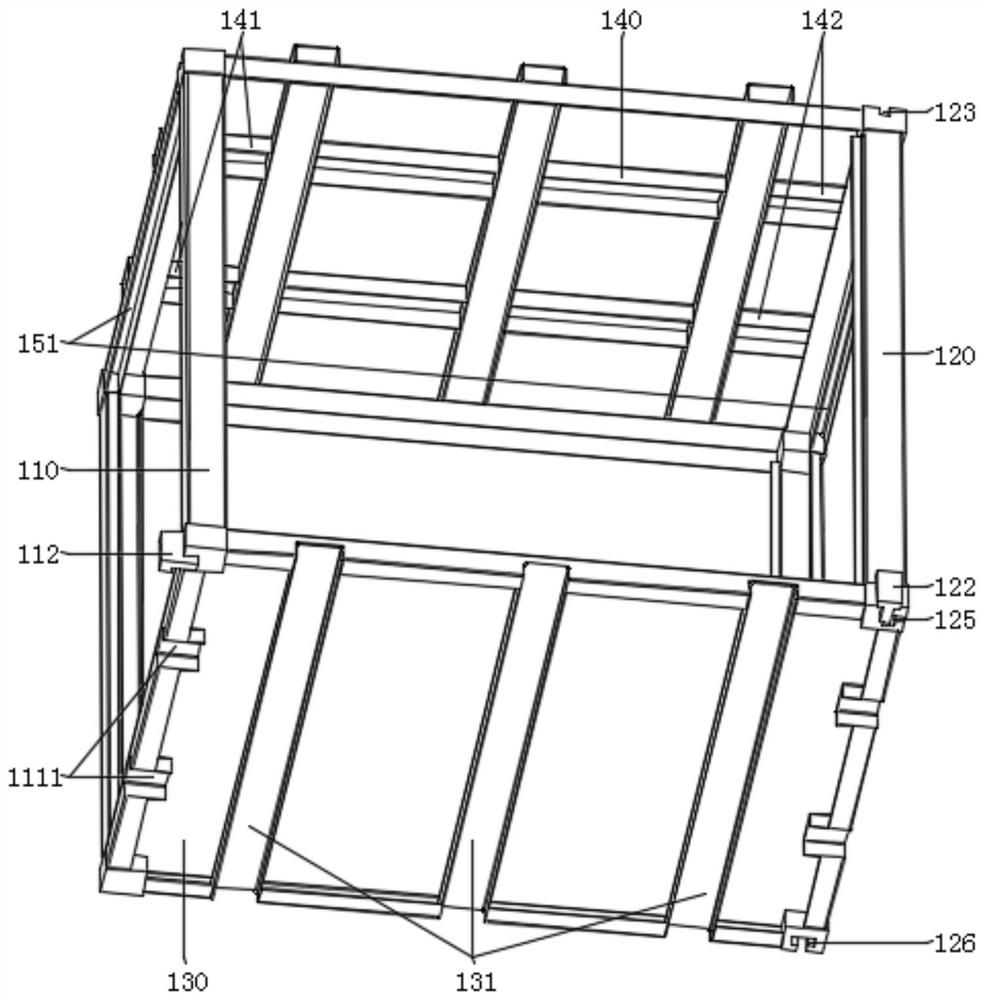

[0032] see figure 1 , 2 , 3 and 4, the present invention provides a technical solution: a modular beam frame of a prefabricated house includes a beam frame main body 100, and the beam frame main body 100 adopts modular assembly, which has good applicability and more convenient assembly.

[0033] see figure 1 , 2, 3 and 4, there are at least four beam frame main bodies 100. In this embodiment, the beam frame main bodies 100 are modular house frames, which are basic units for assembly of prefabricated houses. The beam frame main bodies 100 include first side beam frames 110, The second side beam frame 120, the bottom beam frame 130 and the top beam frame 140, the first side beam frame 110 lower end is provided with the first protrusion 111, the first side beam frame 110 is connected with the first protrusion 111 bolts, the second side The lower end of the beam frame 120 is provided with a second protrusion 121, the second side beam frame 120 is bolted to the second protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com