Multi-supporting post anti-floating box body for cast-in-place concrete hollow floor slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

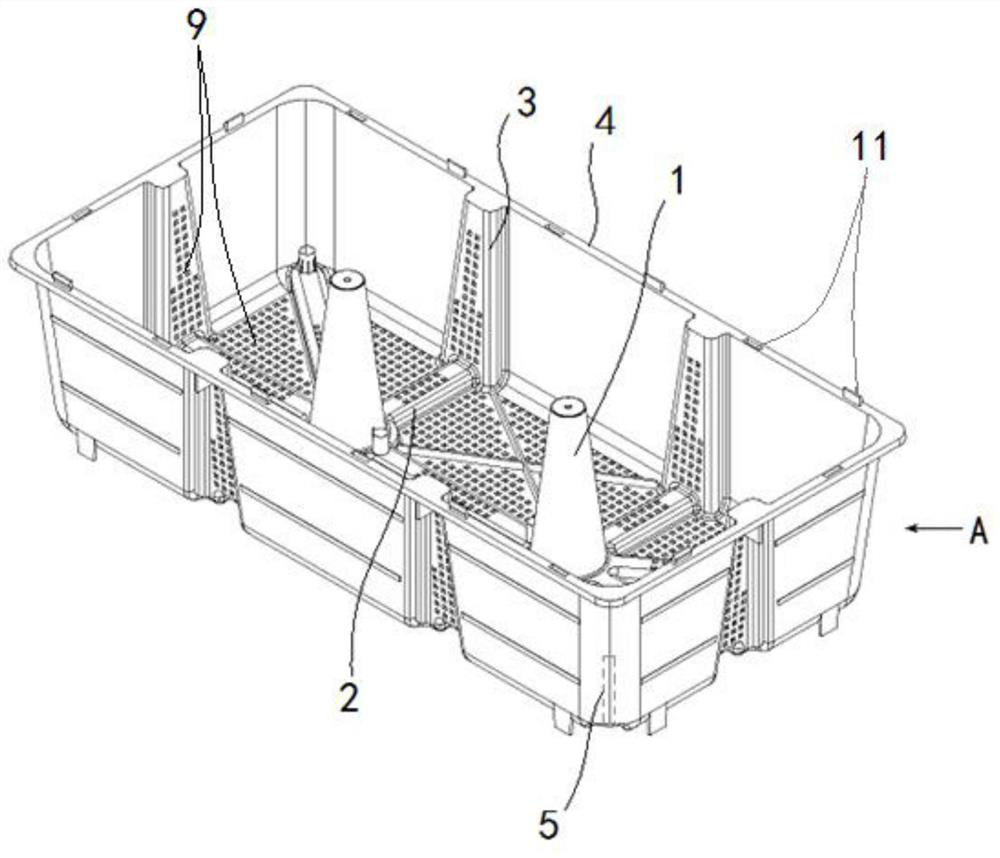

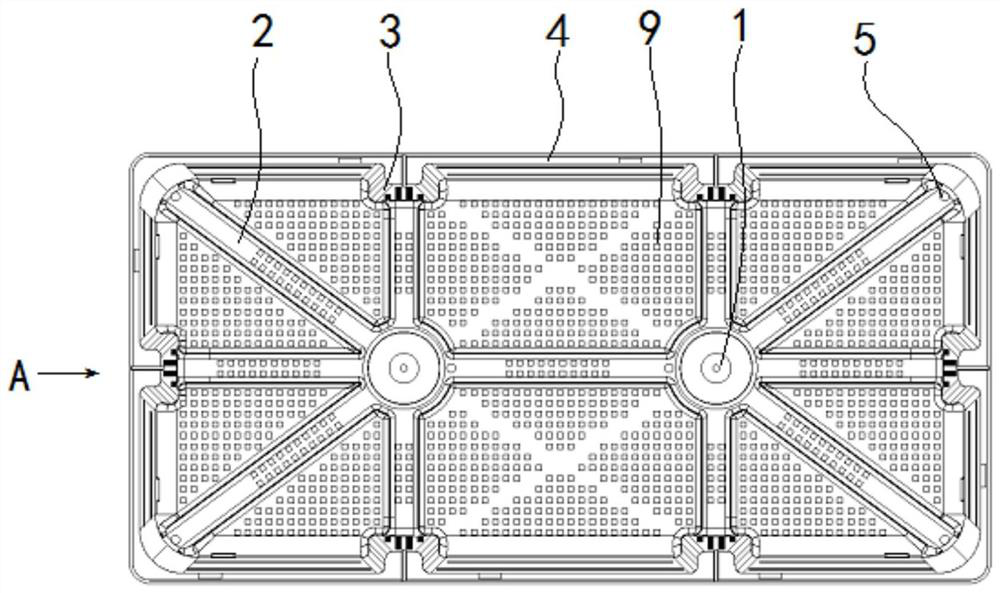

[0027] attached by figure 1 , 2 As shown: the multi-pillar anti-floating tank includes a tank body A, which is characterized in that: the tank body A is a cubic groove structure, and at least two pillars 1 perpendicular to the bottom surface are evenly distributed inside the tank body A , the bottom surface of the box body A is processed with rice-shaped reinforcing ribs 2 with vent holes 9, and vent holes 9 are evenly distributed between the reinforcing ribs on the bottom surface of the box body A, and the four sides of the box body A Vertical ribs 3 with air vents 9 are processed on each side, the upper end of the side of the box body A has a circumferential fixed edge 4, and the four corners of the box body A are vertically processed with supports Leg mounting holes 5.

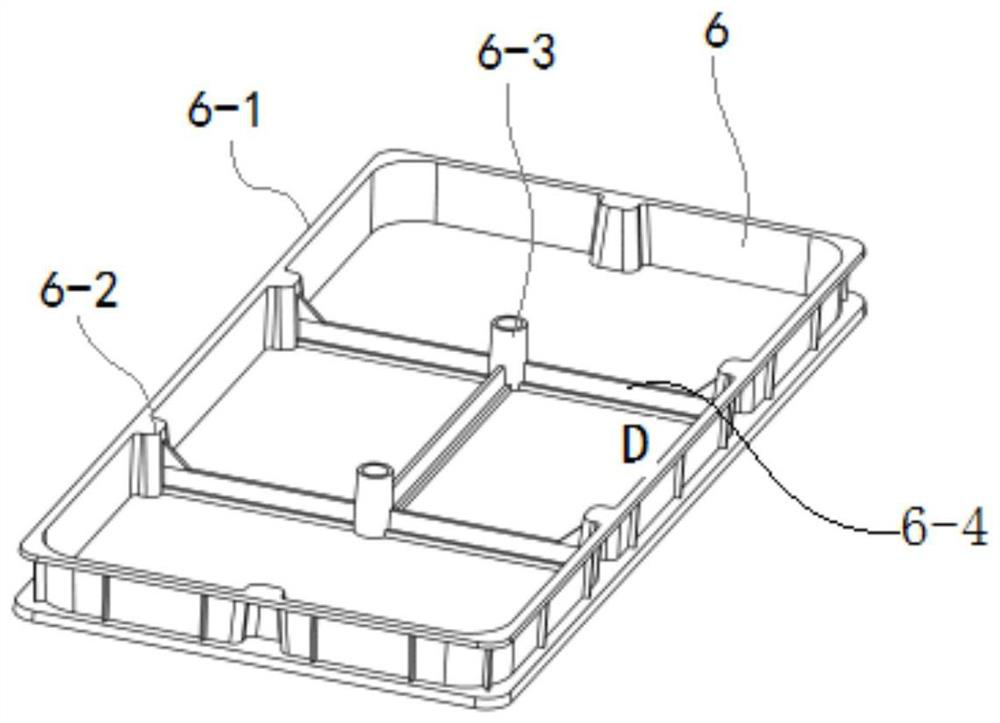

[0028] attached by image 3 As shown: the multi-pillar anti-floating tank also includes a tank heightening section D6, which is arranged on the end face of the tank body during assembly, and the box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com