Drilling slag treatment vehicle and drilling slag construction method

A construction method and technology for handling vehicles, which are applied in the direction of motor vehicles, earth drilling, and object transportation vehicles, etc., can solve problems such as difficult to achieve solid-liquid separation, pollution left over from transportation, secondary pollution, etc., and achieve small footprint, Effect of reducing sand concentration and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This implementation case is aimed at the treatment of drilling slag and mud during the construction of reverse circulation bored piles.

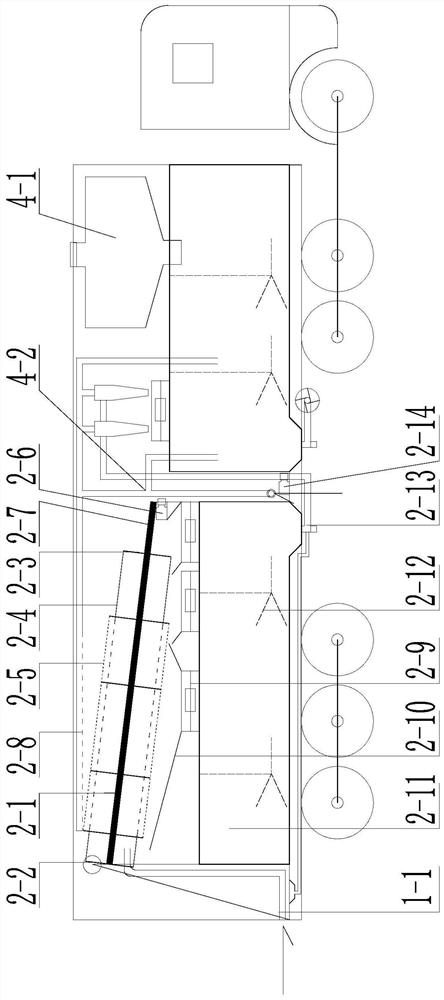

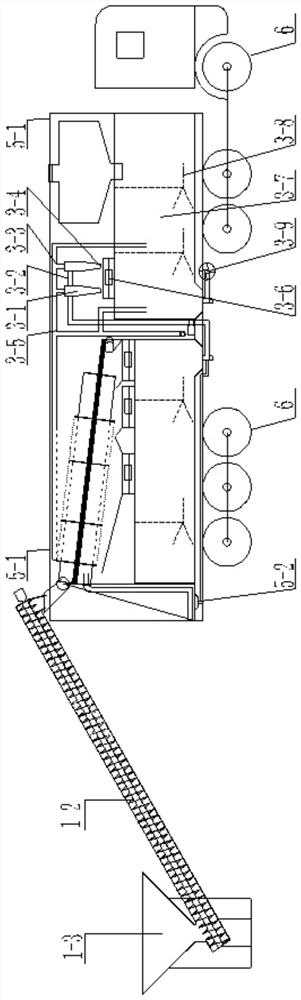

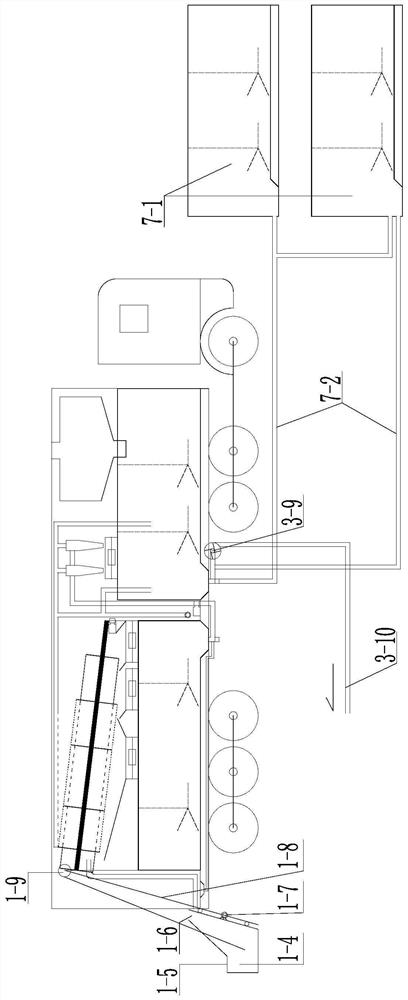

[0034] Such as figure 1 , figure 2 , image 3 As shown, a drilling slag processing vehicle includes a power locomotive, and the drilling slag conveying system 1 is connected to the drilling slag separation and dehydration system 2 provided on the walking chassis 6. The drilling slag separation and dehydration system 2 is connected to the mud treatment system 3 through the slurry discharge communication port. A mud preparation system 4 is arranged above the mud treatment system 3 .

[0035] The power locomotive of the present invention is an existing vehicle locomotive, the rear of the power locomotive is connected with the walking chassis 6, and the power locomotive drives the walking chassis 6, so that the drilling slag processing vehicle can move at any time. Compared with the existing drilling slag processing system, the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com